Method for actuating a braking system

A braking system and braking force technology, applied in the direction of braking safety systems, brakes, brake components, etc., to achieve the effect of improving driving characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

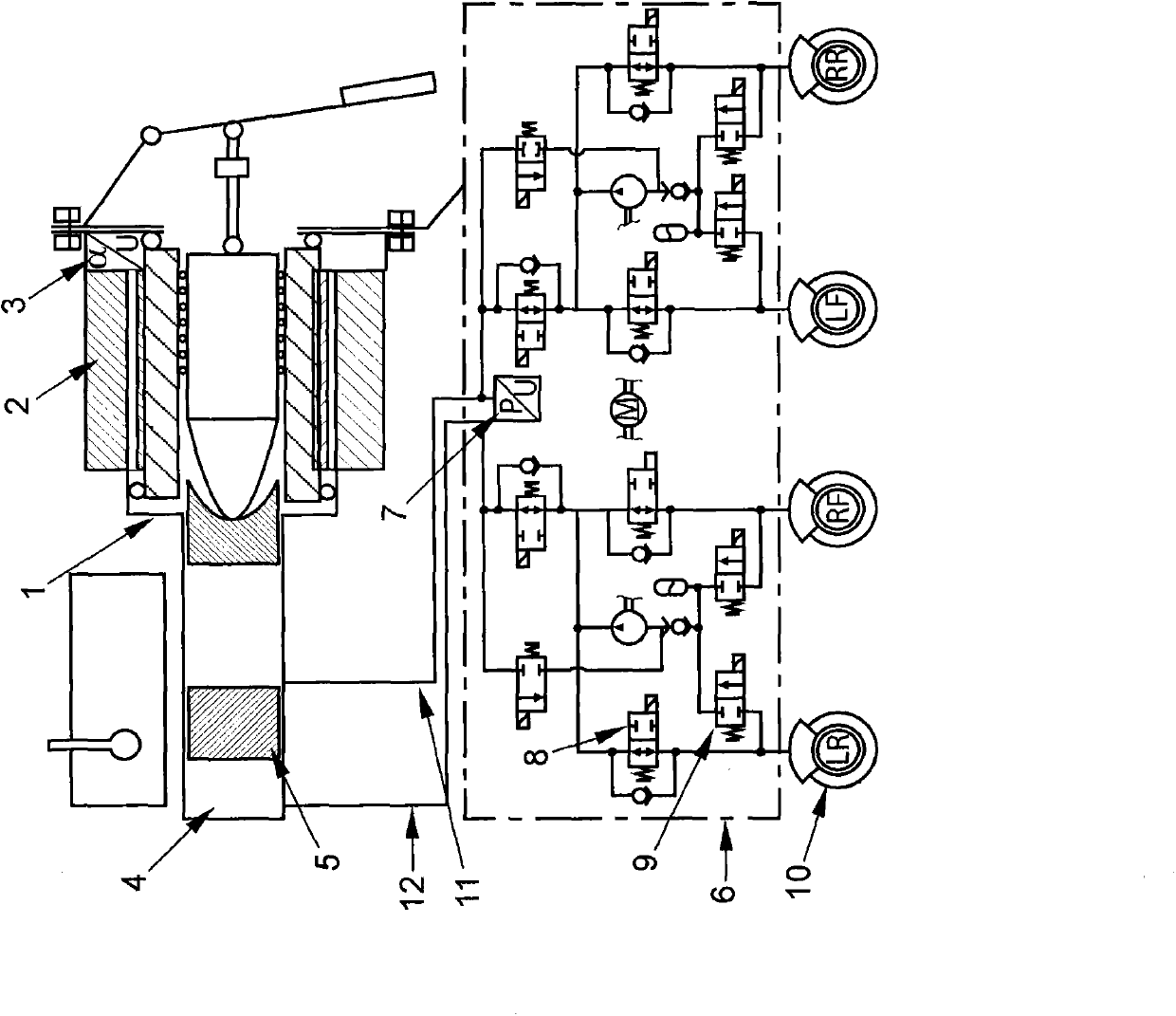

[0021] The braking system is equipped with an electric brake booster 1 having a commutator electric motor as drive 2 . In the exemplary embodiment shown, the drive mechanism 2 detects the corresponding adjustment position with an angle sensor 3 . The brake system also includes a slip control system 6 with a pressure sensor 7 with which the hydraulic pressure in one of the two brake circuits is detected. The two brake circuits are connected to each other via the floating piston 5 of the tandem master cylinder 4 . This makes the brake pressure equal in both brake circuits. In normal operating conditions, each adjustment position of the drive mechanism 2 is assigned a certain pressure in the brake circuit, so that this assignment is clearly indicated by the characteristic curve. During the test cycle, a certain drive torque is generated by correspondingly controlling the drive mechanism 2 , to which a certain pressure is assigned according to the characteristic curve. This dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com