Heavy-duty four-axle dump truck frame combined structure in integrated structure

A combined structure, dump truck technology, applied in the substructure, vehicle parts, transportation and packaging, etc., can solve the problems of increasing the curb weight of the whole vehicle, high production cost, unfavorable economy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A detailed description will be given below in conjunction with the accompanying drawings.

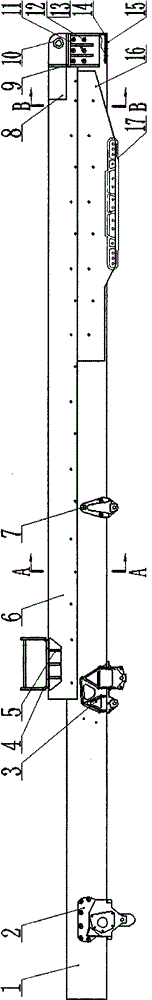

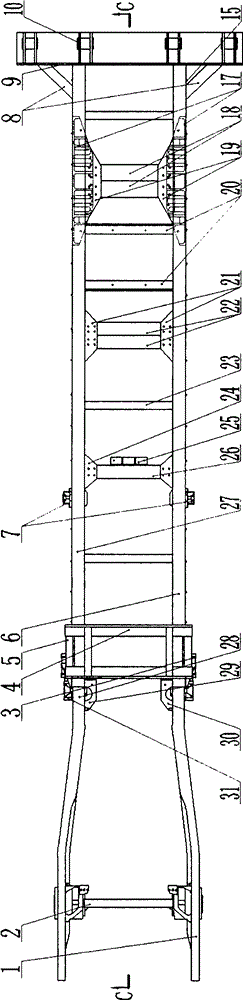

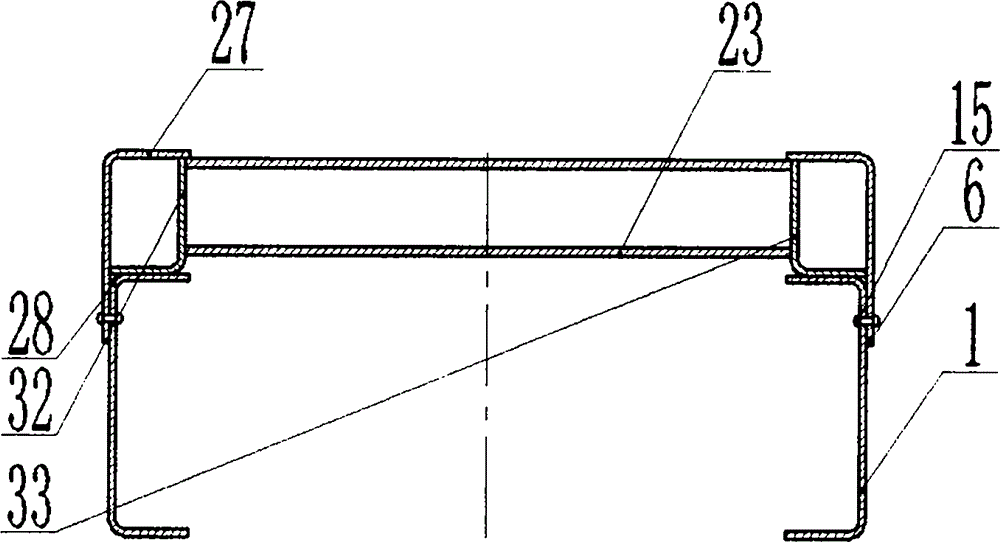

[0022] Such as Figure 1~5 Shown, the parts that need to be installed on the vehicle frame---the rear balance suspension support 17 represents with double dot dash line, does transparent processing. In the four-axle heavy-duty dump truck frame and sub-frame of the integrated structure provided by the present invention, the left longitudinal beam 1 of the vehicle frame is pressed into a groove shape with a special girder steel plate, and the outer sides of the front section and the rear section of the left longitudinal beam 1 of the vehicle frame are Not in one plane, that is, the total width of the front section frame is greater than that of the rear section, so as to ensure the installation needs of engines with larger power and size. Vehicle frame right longitudinal beam 28 is also pressed and formed with special-purpose beam steel plate, and vehicle frame left longitudinal be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com