A power system of a new energy vehicle

A technology for new energy vehicles and power systems, applied in the field of new energy vehicles, can solve problems such as long debugging cycle, and achieve the effect of saving high-voltage wiring harness, reducing volume, and shortening debugging cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

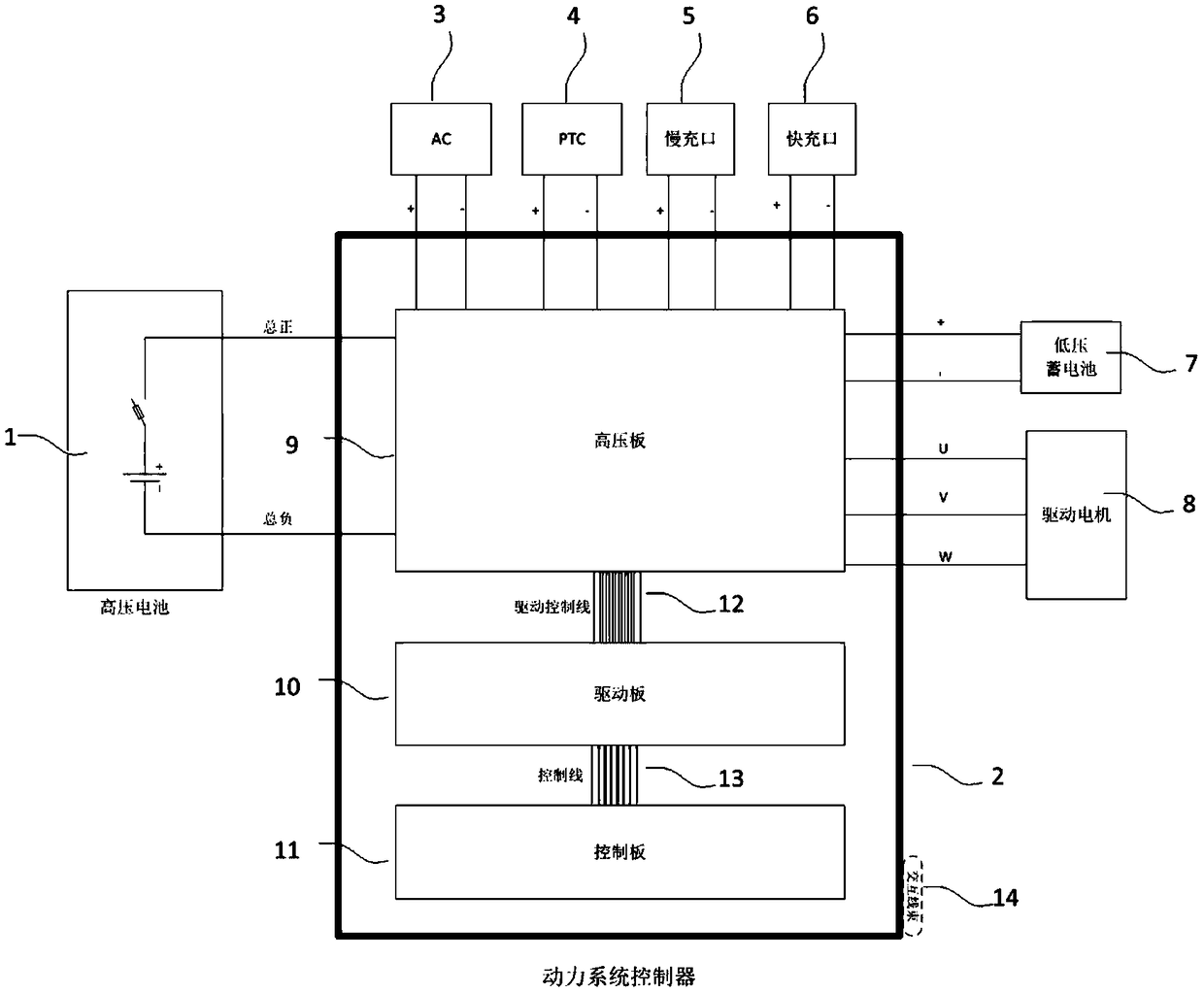

[0024] The present invention considers five independent controllers of the high-voltage system, and has disadvantages such as long R&D and debugging period, high R&D and batch costs, scattered controller strategies, and large quality ratio. According to the functional characteristics of the high-voltage system of electric vehicles. Invented a new energy vehicle power system integration scheme. To integrate five independent high-voltage control systems into a single controller, this solution uses multi-core control chips to reduce software complexity.

[0025] Such as figure 1 As shown, the new energy vehicle power system controller 2 is composed of a control board 11 , a drive board 10 , a high voltage board 9 , a signal control line 13 , a drive control line 12 , and an interactive wiring harness 14 .

[0026] Among them, the control board 11 is composed of a processing chip, which mainly realizes driver demand analysis, vehicle torque drive, vehicle high-voltage power-on / o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com