Heat-resistant battery bracket, machining die and preparation method thereof

A battery, heat-resistant technology, applied in circuits, electrical components, battery pack components and other directions, can solve problems such as easy corrosion, all-metal battery brackets increase vehicle energy consumption, affect service life, etc., to achieve extended service life, The effect of reducing curb weight and preventing rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

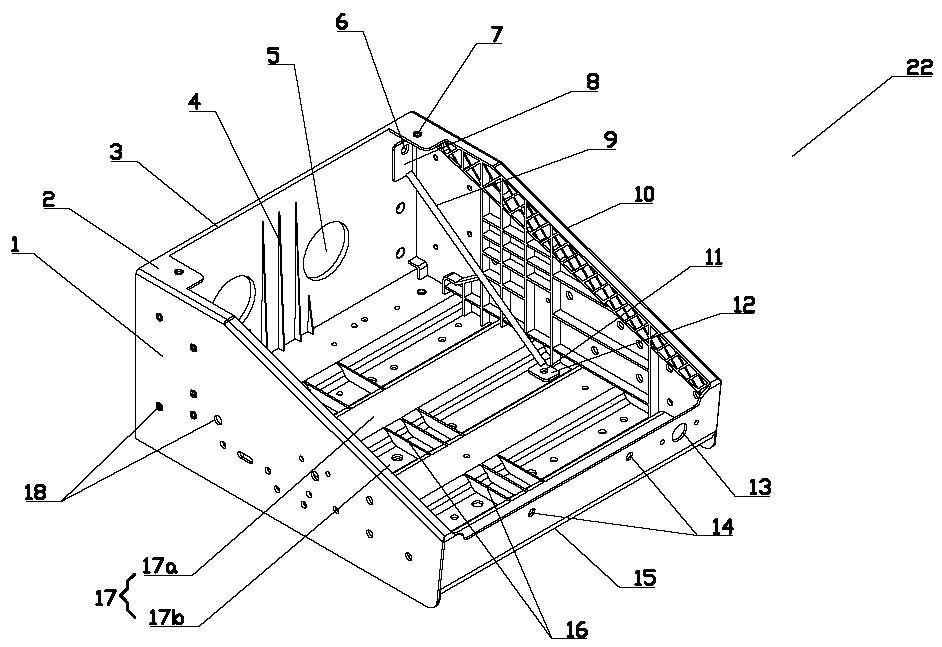

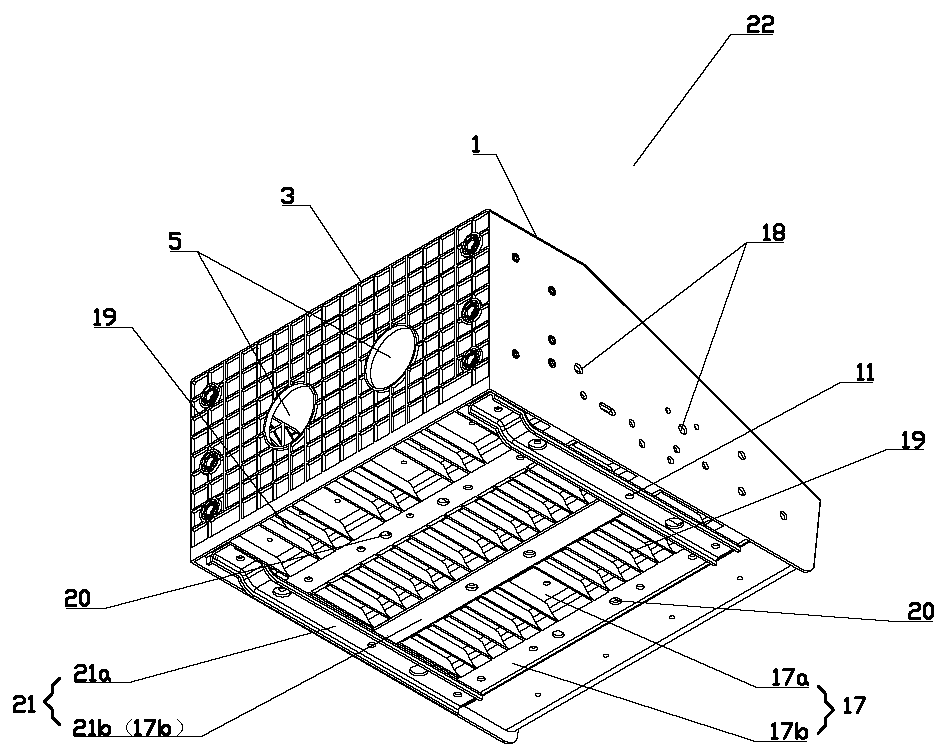

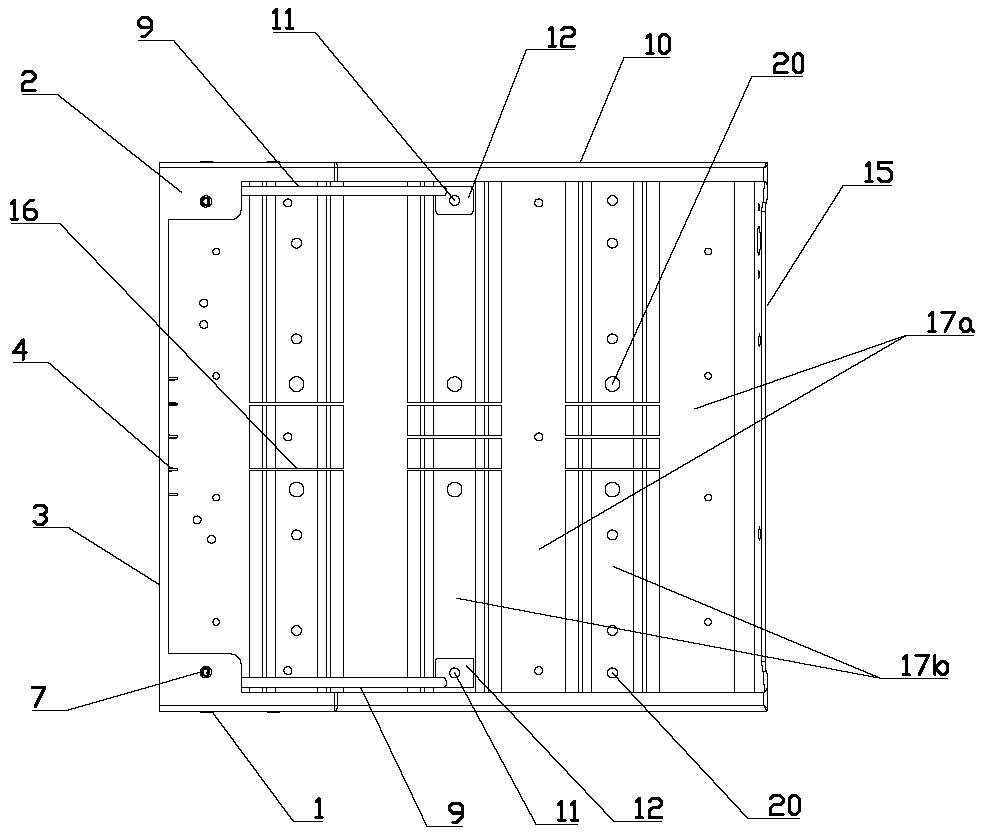

[0031] Attached below Figure 1~6 To further explain the present invention:

[0032] Such as Figure 1~4 As shown, the present invention provides a heat-resistant battery bracket, which includes a bottom plate 17, the bottom plate 17 is provided with battery mounting holes 20, along the width direction of the bottom plate 17, the two ends of the bottom plate 17 are connected with mutually parallel left plates 1 and the right side plate 10, both the left side plate 1 and the right side plate 10 are provided with electrical component mounting holes 18, along the length of the bottom plate 17, at one end of the bottom plate 17, between the left side plate 1 and the right side plate 10. A first baffle 15 is connected. The first baffle 15 is provided with a wire inlet 13 and a cover connection hole 14. At the other end of the bottom plate 17, a second baffle is connected between the left side plate 1 and the right side plate 10 Board 3, the second baffle 3 is symmetrically provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com