Novel side manhole

A new type of manhole cover technology, applied in the field of milk tankers, can solve the problems of easy entry of dust, high risk, inconvenient use, etc., and achieve the effect of reducing curb quality and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

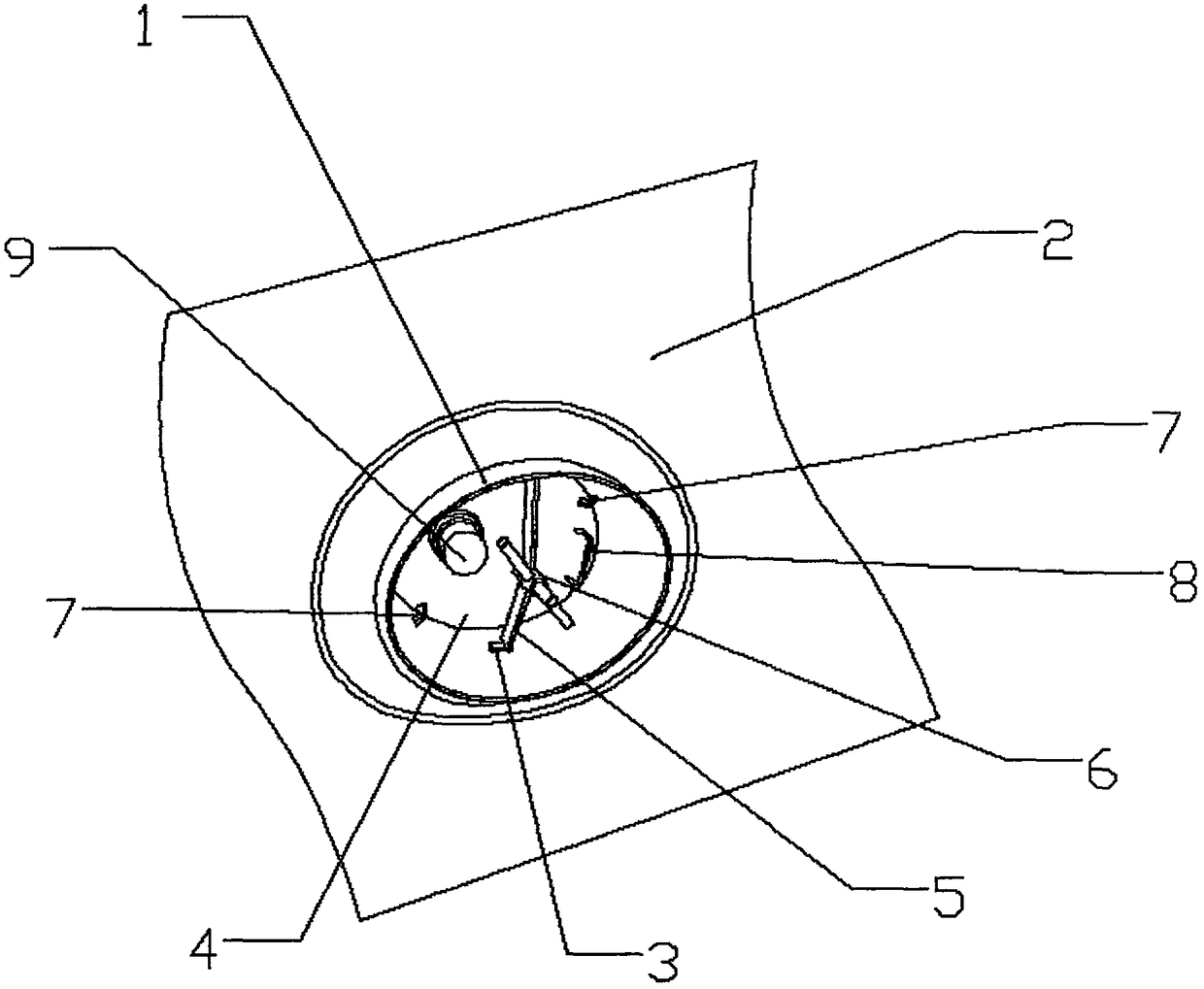

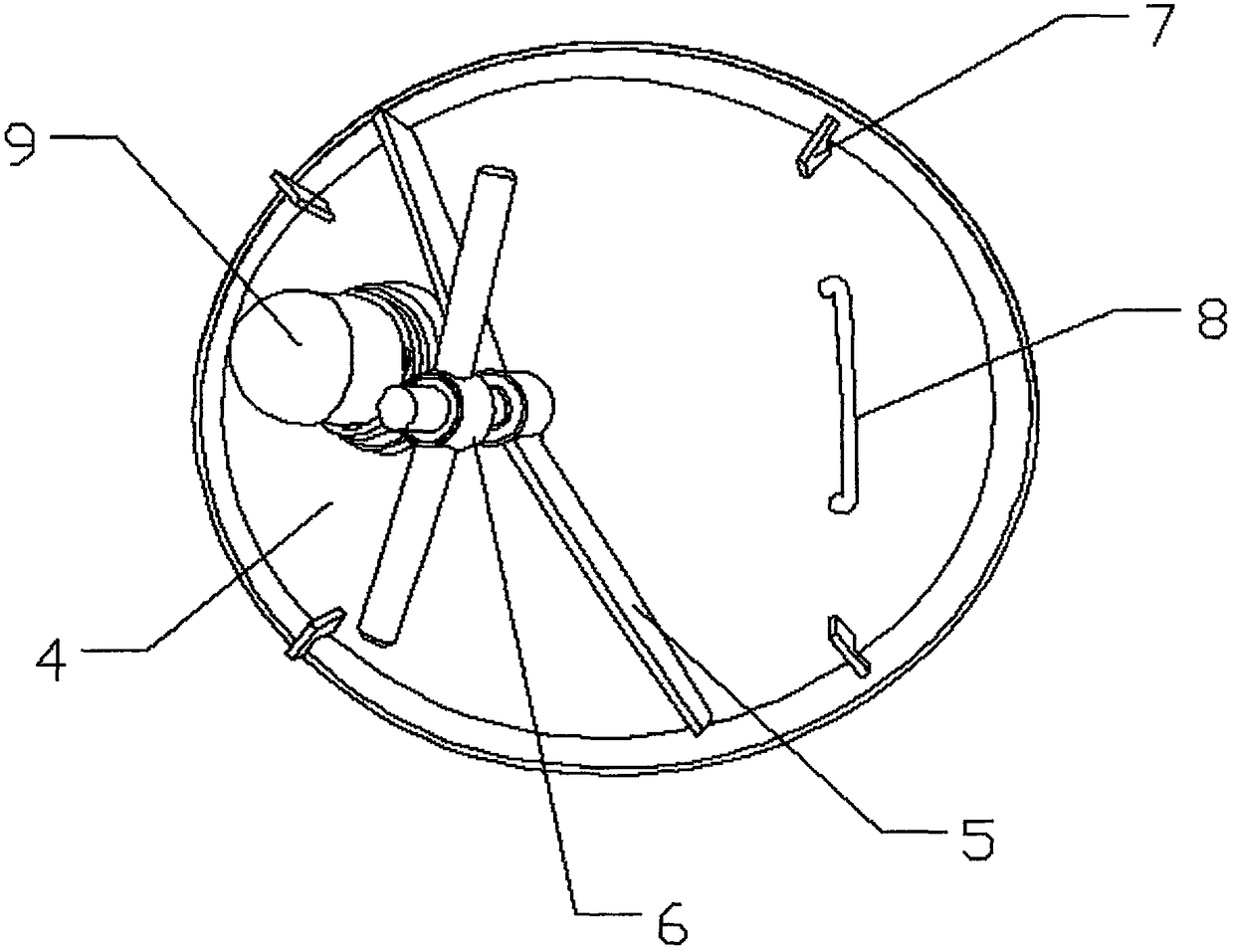

[0013] see Figure 1-2 , a new type of side manhole, including a side manhole shell 1, a milk tank car body 2, a block 3, a manhole cover 4, a support device 5, a locking device 6, a positioning plate 7, a handle 8 and a sampling device 9 The side manhole housing 1 is arranged on the side lower part of the milk tanker tank body 2, and the side manhole housing 1 is in the shape of a nozzle and communicates with the milk tanker tank body 2; the side manhole housing 1 of the The shape can be circular or oval; two blocks 3 are symmetrically arranged on the side wall of the side manhole housing 1; a manhole cover 4 is arranged inside the side manhole housing 1; A locking device 6 is provided, and the bottom of the locking device 6 is symmetrically provided with two support devices 5, and the end of the support arm of the support device 5 is against the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com