Omnidirectional Mobile Platform and Its Powered Universal Wheels

A universal wheel and power technology, applied in the field of mobile platforms, can solve the problems of discontinuous contact, vibration, slippage, etc., and achieve the effects of smooth steering motion, high motion control precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

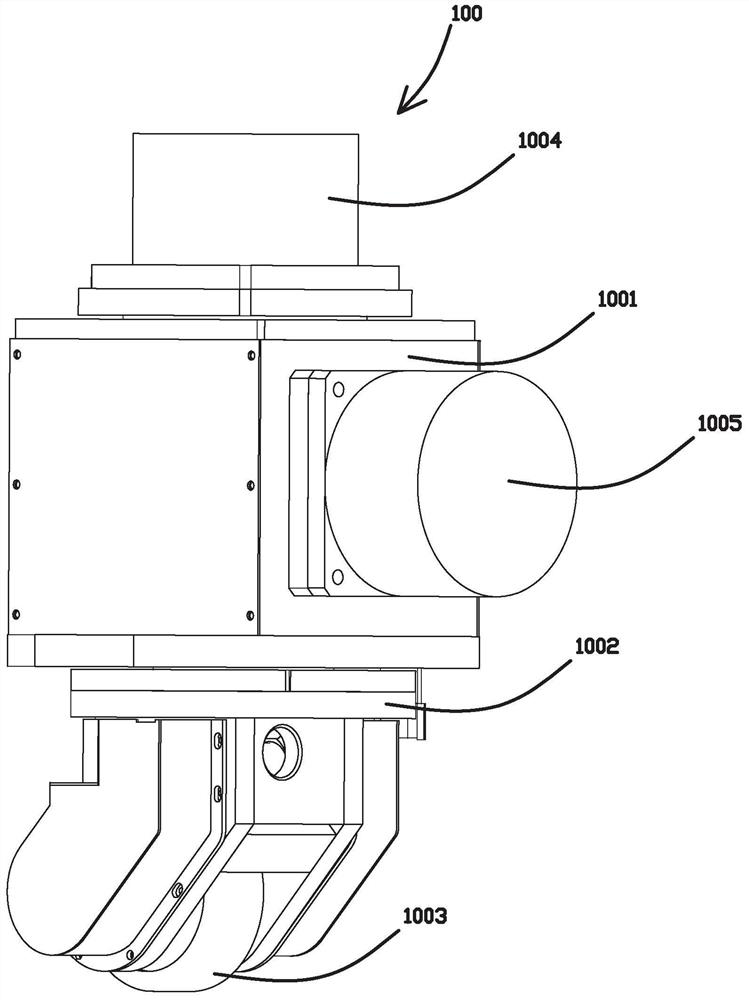

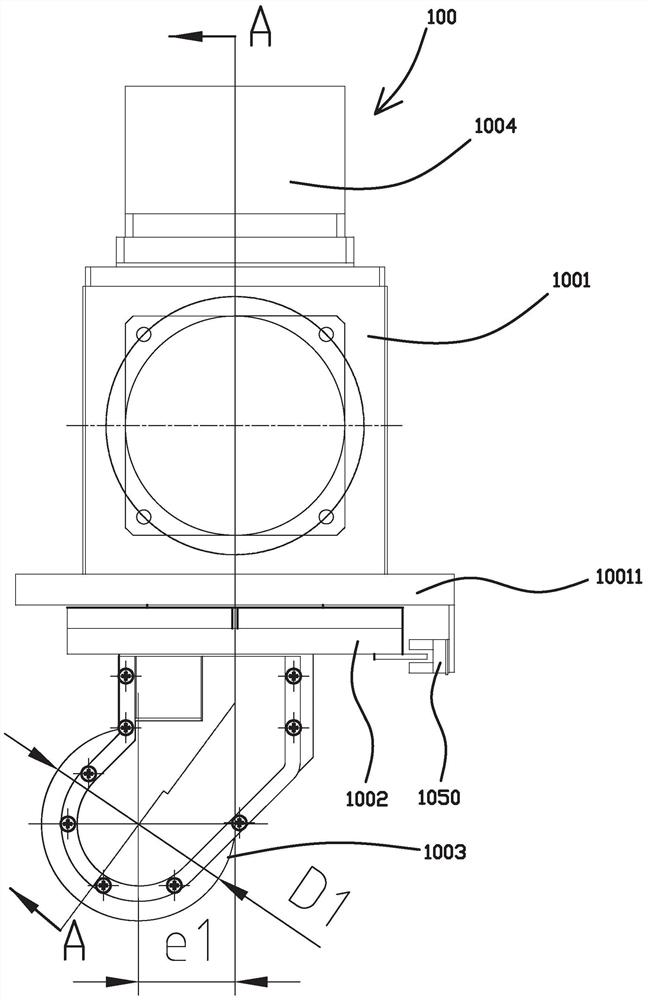

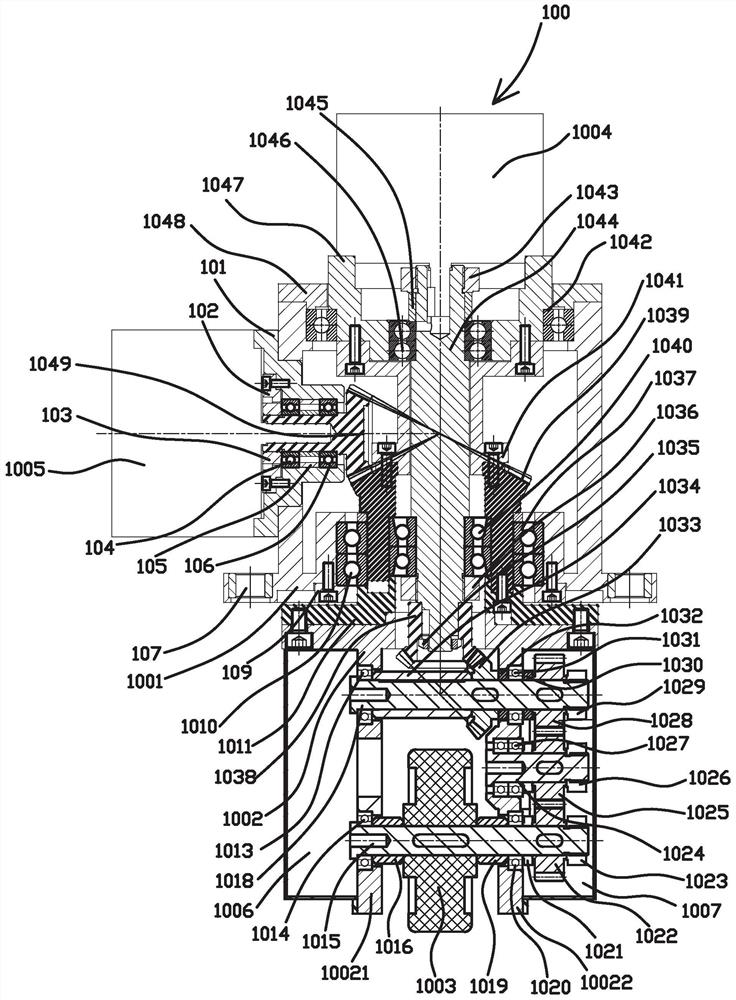

[0048] Such as Figure 1-3 As shown, the front-mounted power universal wheel 100 includes a housing 1001 (or an upper frame body), a lower frame body 1002 and a roller 1003, wherein the lower frame body 1002 is rotatably connected to the housing 1001, and the roller 1003 can rotate the lower frame Body 1002. The motor 1004 is installed on one side of the casing 1001 and drives the lower frame body 1002 to rotate through the transmission system inside the casing 1001 to realize the steering movement. The motor 1005 is installed on the other side of the casing and drives the roller 1003 to roll through a corresponding transmission system to realize translational movement.

[0049] Specifically, the front-mounted power universal wheel 100 is mainly composed of the following parts, namely: a motor base 101, a gland 102, a lock nut 103, a bearing 104, a shaft sleeve 105, a bearing 106, a bearing sleeve 107, and a housing 1001, gland 109, bearing 1010, gland 1011, lower frame body...

Embodiment 2

[0058] Figure 4-5 A schematic structural diagram of a front-mounted power universal wheel 200 according to a second embodiment of the present invention is shown. The front type power universal wheel of the present embodiment and Figure 1-3 The difference of the power universal wheel in the illustrated embodiment is that the driving motion of the power universal wheel in this embodiment is realized by the hub motor, correspondingly, the transmission system required to realize the driving motion in the above embodiment is cancelled. .

[0059] Such as Figure 4-5 As shown, the front-mounted power universal wheel 200 includes a housing 2001 (or an upper frame), a lower frame 2002 and a roller 2003, wherein the lower frame 2002 is rotatably connected to the housing 2001, and the roller 2003 is installed on the hub motor 2004 and mounted on the lower frame body 2002 together with the hub motor 2004, so that the roller 2003 rolls relative to the lower frame body 2002 to realize...

Embodiment 3

[0063] Figure 6-7 A schematic structural diagram of a front-mounted power universal wheel 300 according to a third embodiment of the present invention is shown. The front type power universal wheel 300 of the present embodiment and Figure 4-5 The difference of the power universal wheel 200 of the illustrated embodiment is that the steering movement of the power universal wheel in this embodiment is also realized by the hub motor, and correspondingly, the Figure 4-5 In the embodiment shown, the drive train required to achieve the steering movement.

[0064] Such as Figure 6-7 As shown, the front-mounted power universal wheel 300 includes a housing 3001 (or an upper frame), a lower frame 3002 and a roller 3003, wherein the lower frame 3002 is rotatably connected to the housing 3001, and the roller 3003 is installed on the hub motor 3004 and is mounted on the lower frame body 3002 together with the hub motor 3004, so that the roller 3003 rolls relative to the lower frame b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com