Wheel set handling robot

A technology for handling robots and wheel sets, which is applied in motor vehicles, transportation and packaging, etc., can solve the problems of low operation efficiency, long maintenance process lines, and high labor intensity, and achieve the effects of compact structure, high degree of automation, and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

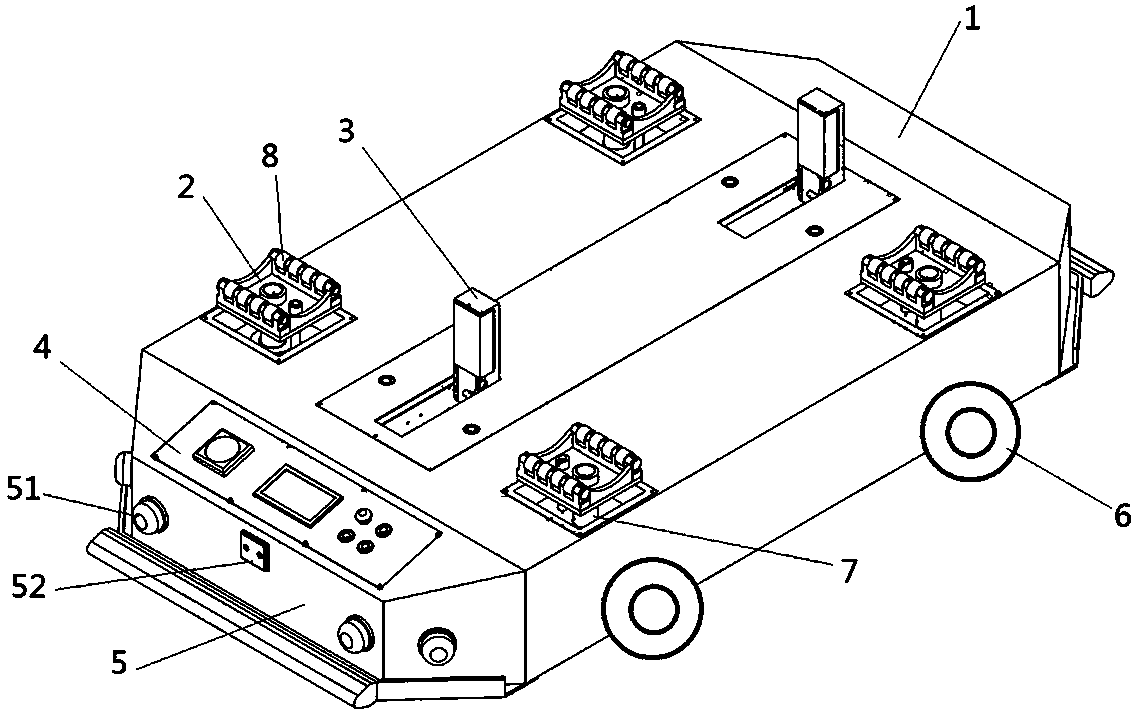

[0019] Below in conjunction with accompanying drawing, the present invention is further described:

[0020] refer to figure 1 As shown, a wheel set handling robot includes a frame 1, a drive system, a power supply, a guidance system, a hydraulic auxiliary system, a wheel set carrying mechanism 2, an axle positioning mechanism 3, a control panel 4 and a safety protection system 5. The four corners at the bottom of the frame are provided with drive wheels 6, which are driven by a drive system, and the drive system is mainly composed of a brushless DC motor and a reducer; the front end of the frame 1 is provided with a safety protection system 5 and a control system. Panel 4, safety protection system 5 is made up of anti-collision stopper 51 and distance sensor 52; Said control panel 4 includes touch screen 41, operation button 42 and emergency stop switch 43; Frame 1 upper part is provided with at least one pair of wheels Bearing mechanism 2, an axle positioning mechanism 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com