Double-cone-wheel transmission for bicycle

A double tower wheel and transmission technology, which is applied in the direction of vehicle gearboxes, vehicle components, chain/belt transmissions, etc., can solve the problem of not being able to meet the requirements of riding speed and riding movement, lack of comfort and sportiness, and riding Limited speed and other issues, to achieve a large gear ratio, easy maintenance, and reduce tooth side wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

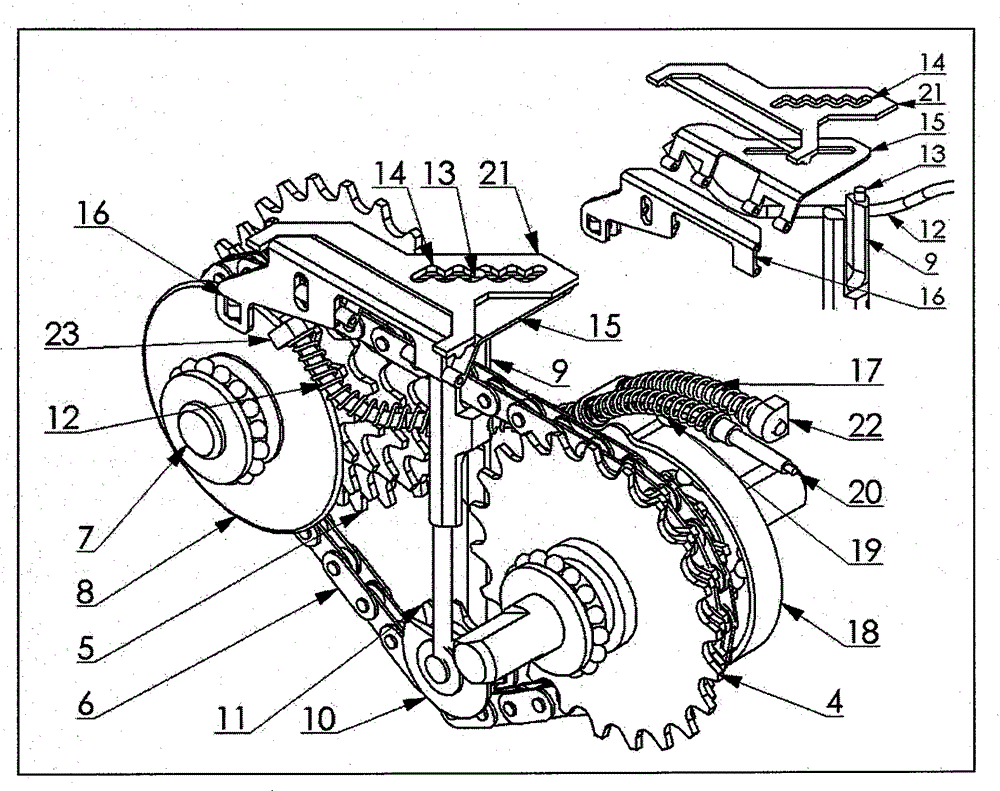

[0018] The present invention refers to the standard chain number 082C of the national standard of the People's Republic of China (ISO9633:2001, ITD) about the speed-changing bicycle chain. The pitch is 12.7mm, and the chain width is 7.4-8.2mm.

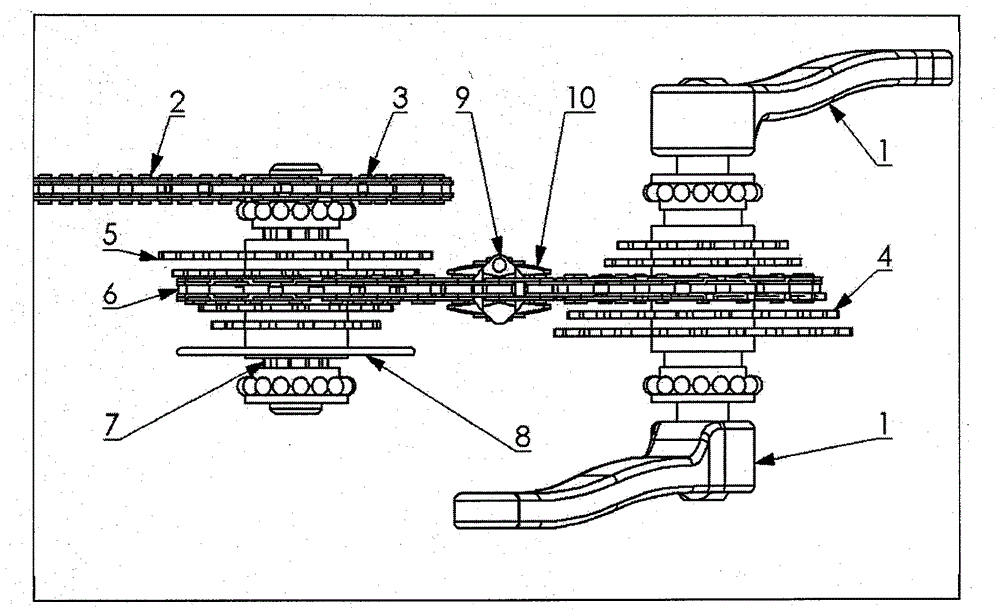

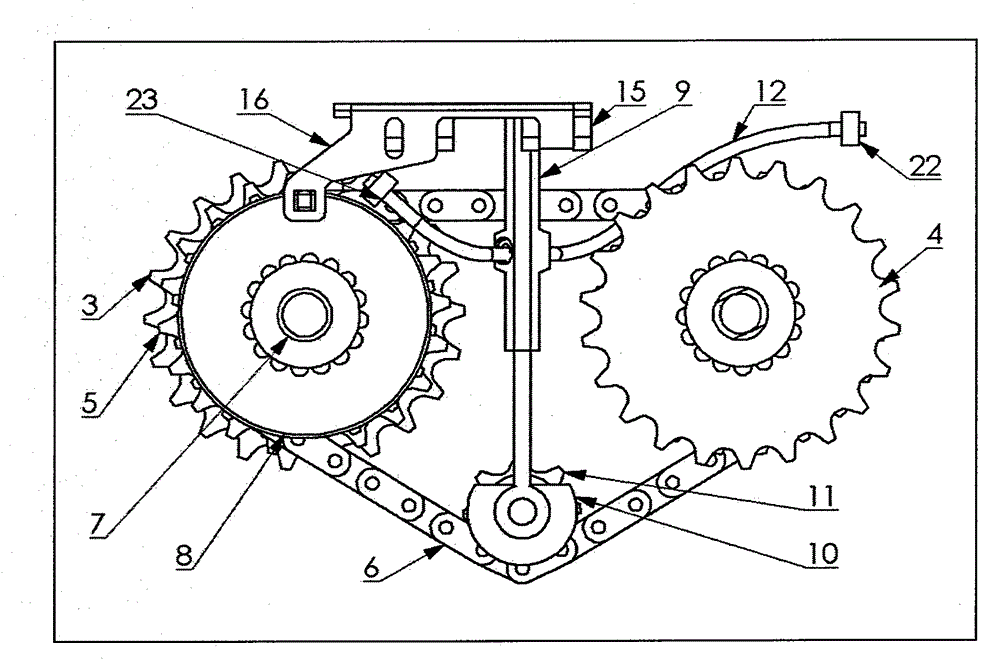

[0019] attached figure 1 , attached figure 2 They are the top view and the front view of the double tower transmission structure respectively. These include: 1 pedal lever, 2 external chain, 3 driving sprocket, 4 driving sprocket, 5 passive sprocket, 6 internal chain, 7 sliding coupling, 8 passive sprocket dial, 9 chain upper fork, 10 Chain lower shift fork, 11 tensioning wheel, 12 curved guide rail, 15 transverse paddle, 16 transverse shift fork, 22 fixed end of curved guide rail on the left side of the housing, 23 fixed end of curved guide rail on the right side of the housing. Pedal rod (1) drives driving sprocket (4), and the external large sprocket (3) on the driven wheel shaft (7) drives rear wheel to rotate through external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com