Grain conveyer special rotary disc

A technology of rotating discs and conveyors, applied in conveyors, rotary conveyors, transportation and packaging, etc., can solve the problems of ineffectiveness, small conveying range and low working efficiency of conveyors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

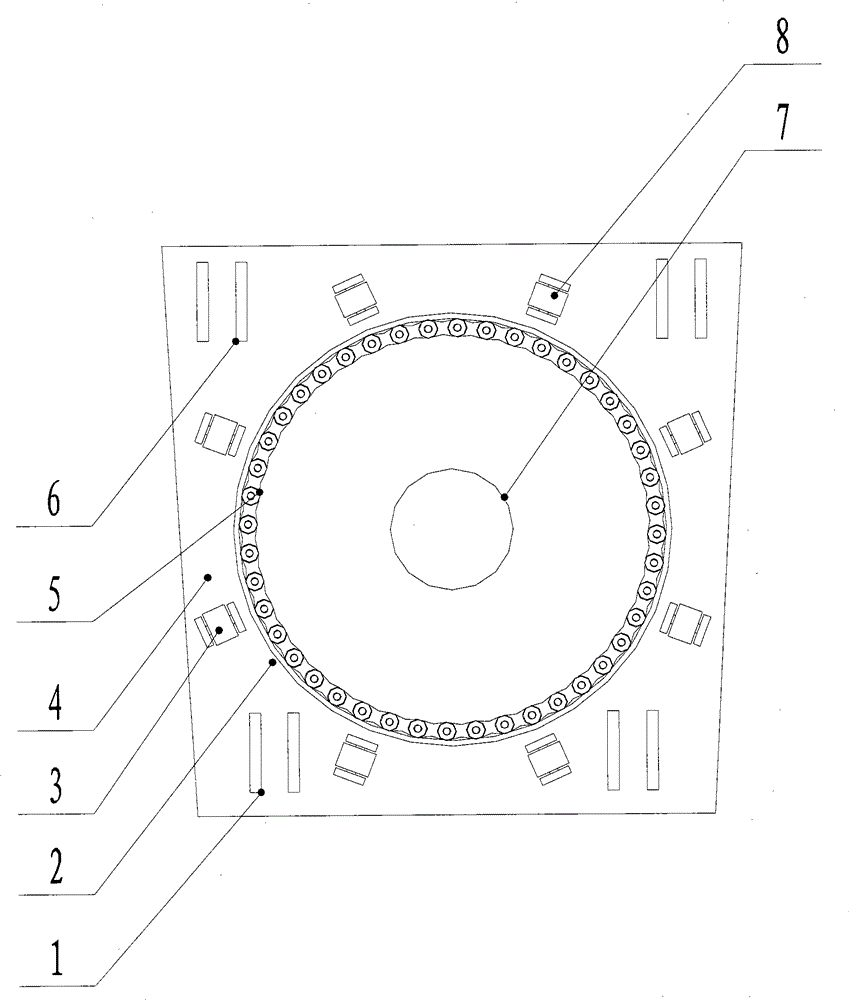

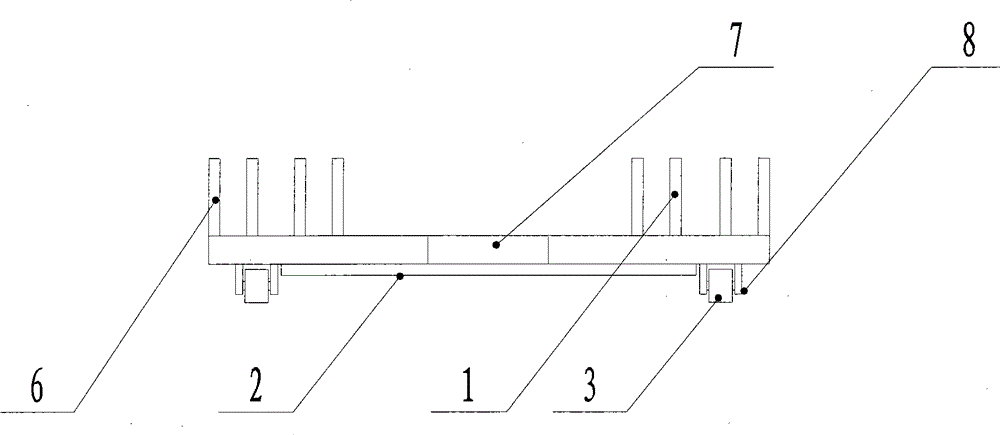

[0010] Products involved in the present invention such as figure 1 , figure 2 As shown, the double-layer rotating disk 4 is formed by welding two trapezoidal steel plates with support in the middle. A central hole 7 is provided in the center of the double-layer rotating disk 4 for installing rotating components. Two front support frame groups 6 and two rear support frame groups 1 are arranged on the top of the double-deck rotating disk 4, which are used to support the telescopic conveyor frame; the distance between the two front support frame groups 6 is larger than the distance between the two rear support frame groups 1 large, to increase the smoothness of the double-deck rotating disk 4. Eight rotating wheels 3 and passive gear rings 5 are arranged below the double-layer rotating disk 4, the rotating wheels 3 are evenly distributed in a circular array, and the rotating wheel bracket 8 is arranged under the double-layer rotating disk 4 by welding; Connect with swivel w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com