Truss type three-freedom-degree double-pneumatic-gripper grabbing device

A grabbing device and a technology of degrees of freedom, applied in the field of truss-type three-degree-of-freedom double-air gripper grabbing devices, can solve problems such as low action efficiency, burrs on blank parts, and potential safety hazards, so as to avoid manual safety hazards, movement Efficiency improvement and downtime reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

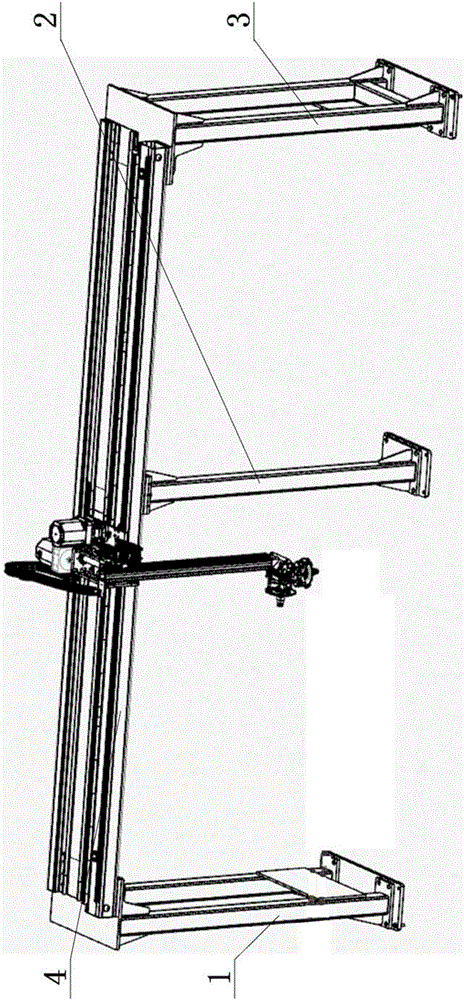

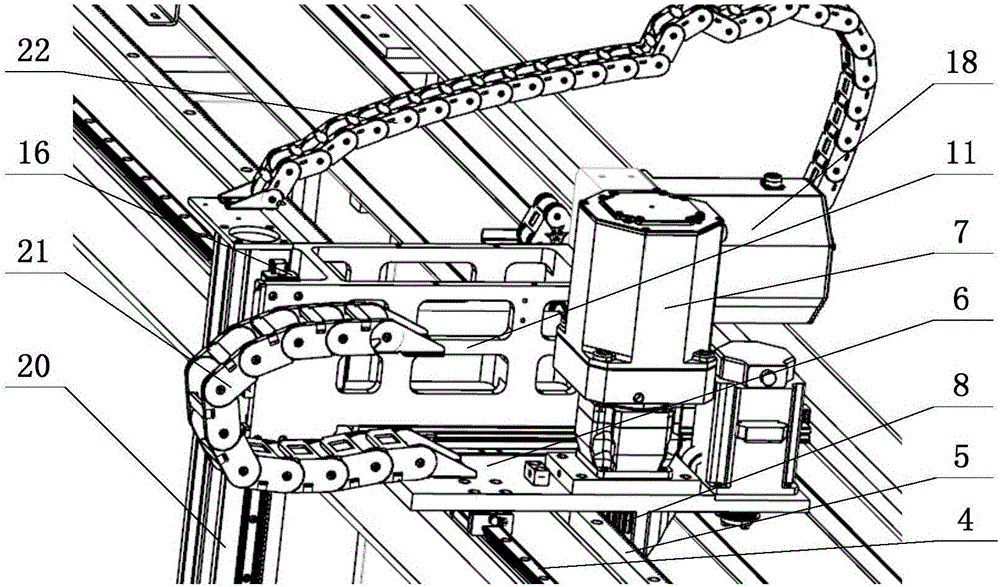

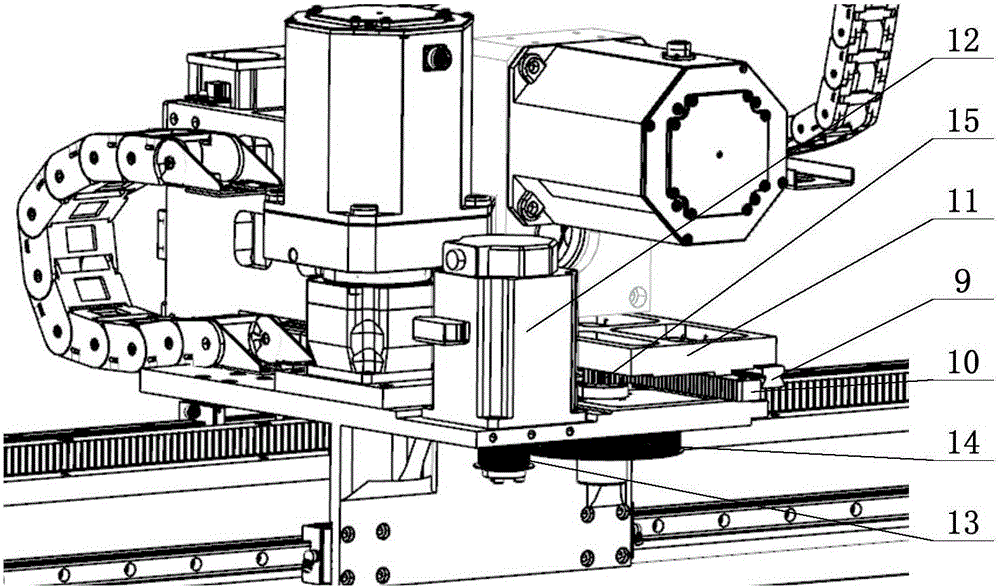

[0021] A truss-type three-degree-of-freedom double-air claw grabbing device, including a left frame 1, a middle frame 2, a right frame 3, a traverse guide rail 4, a traverse rack 5, a traverse slide plate 6, and a traverse motor 7 , horizontal gear 8, vertical guide rail 9, vertical rack 10, vertical slide 11, vertical motor 12, vertical gear 13, middle large gear 14, middle pinion 15, lifting guide rail 16, lifting rack 17 , lifting motor 18, lifting gear 19, lifting slide bar 20, rotary cylinder 23, right-angled triangle connection block 24, first pneumatic three-claw disc 25-1 and second pneumatic three-claw disc 25-2;

[0022] The traverse guide rail 4 is placed horizontally on the left frame 1, the middle frame 2 and the right frame 3, the middle frame 2 is located between the left frame 1 and the right frame 3, and the traverse rack 5 is fixedly connected to On and parallel to the traverse guide rail 4, the traverse slide plate 6 is arranged on the traverse guide rail 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com