Water purifier with turnover cover display window device

A technology for displaying windows and window devices, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. problems, to achieve the effects of intuitive inspection and maintenance, simple machine structure, and stable assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

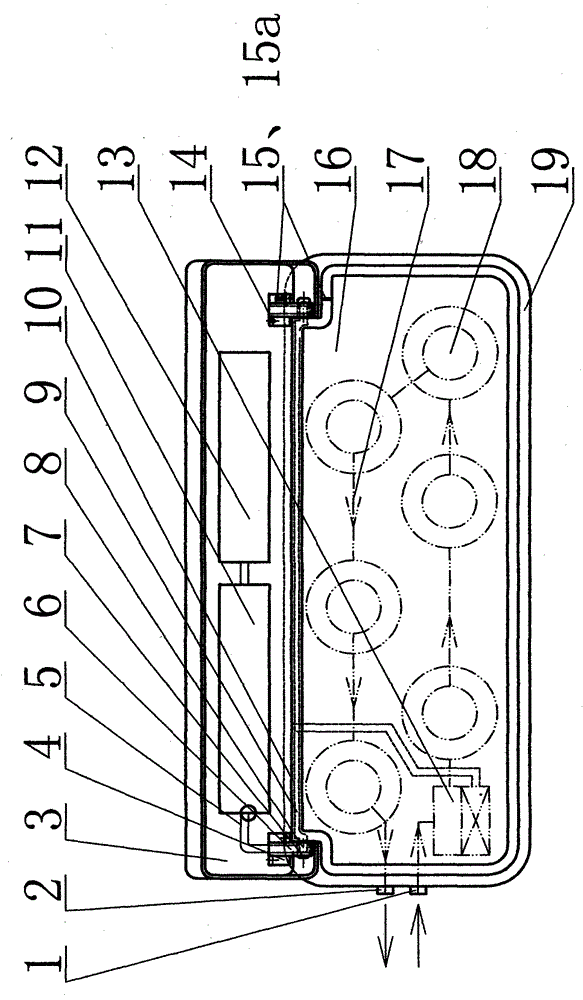

[0028] Example 1. In the accompanying drawings, three pre-closed filter gallbladders 18, and two RO reverse osmosis membrane bare gallbladders 18 adopting an open filter cartridge with a cover, and an open filter cartridge with a cover (not shown) are also used. The post activated carbon filter gallbladder 18 is connected with the water pipeline, and communicates with the machine base inlet and outlet 1,2 respectively to form the filter passage 17. The filter channel 17 is arranged on the bottom plate of the lower filter gall bin 16 . The water pipe butt joint device (not shown) connected in the filter channel 17 is provided with an upward butt joint water port and a respective downward water port of each corresponding filter bladder 18 for sealing insertion. A plurality of water passing control parts of the machine are fixedly connected under the water pipe docking device, and the water passing pipe interface of each water passing control part is connected to the correspondi...

Embodiment 2

[0041] Example 2. On the basis of Embodiment 1, the hinged swing mechanism and the swingable wire passing mechanism adopt a device in which the hollow shaft penetrates through the shaft holes of the vertical ears at both ends of the lower gallbladder bin 16 and the flip cover 3 and is hingedly matched. And the radial hole connecting the hollow shaft hole is set in the middle of the hollow shaft body; simultaneously, the lower line groove 9 and the radial hole of the hollow shaft body are set in the lower gallbladder bin 16 to form a wire passing channel correspondingly. When the vertical ear of the flip cover swings around the hollow shaft body, the wire connected to the electric control device 11 enters the hollow shaft body through one end port of the hollow shaft body, and then passes through the radial hole of the hollow shaft hole and enters the off-line of the gallbladder bin 16. The groove 9 is connected to the water control part in turn.

Embodiment 3

[0042] Example 3. On the basis of the above-mentioned embodiments, the hinged swing mechanism and the swingable wire passing mechanism adopt the flip cover 3 provided with vertical lugs with notched shaft holes and the hollow shaft body supported by the two vertical lugs of the lower gallbladder bin 16 is radially inserted and fixed. Articulated fittings. And on the shaft wall of the hollow shaft body, a radial wire-passing hole connecting the hollow shaft hole is set; at the same time, the lower line groove 9 is set in the lower gallbladder bin 16 to correspond to the radial wire-passing hole of the hollow shaft body to form a wire-passing channel . The wire connected to the electric control device 11 enters the hollow shaft body through one end port of the hollow shaft body, then passes through the radial wire hole of the hollow shaft hole and enters the downline slot 9 of the gallbladder bin 16, and then connects to the water control system. part.

[0043] As an improvem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com