A special separator and spinner for spunbonded non-woven fabrics

A technology of spun-bonded non-woven fabrics and separators, which is applied in the direction of filament generation, non-woven fabrics, textiles, and papermaking, and can solve problems such as increasing the power and flow of suction fans, increasing the number of fibers, and limited improvement, and achieves Improve the uniformity of the tow, prevent the airflow from swirling, and improve the effect of controlling the direction of the tow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

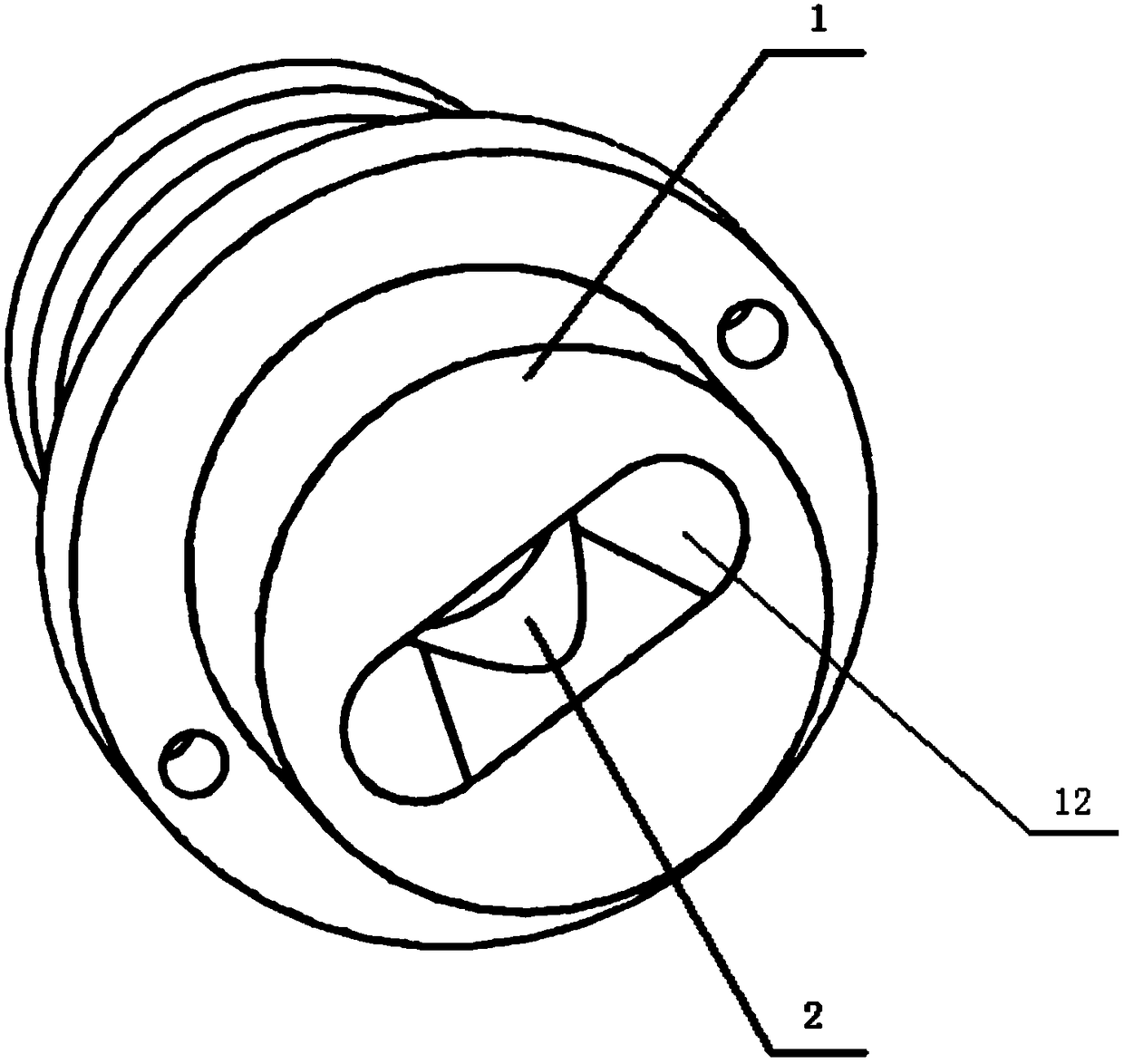

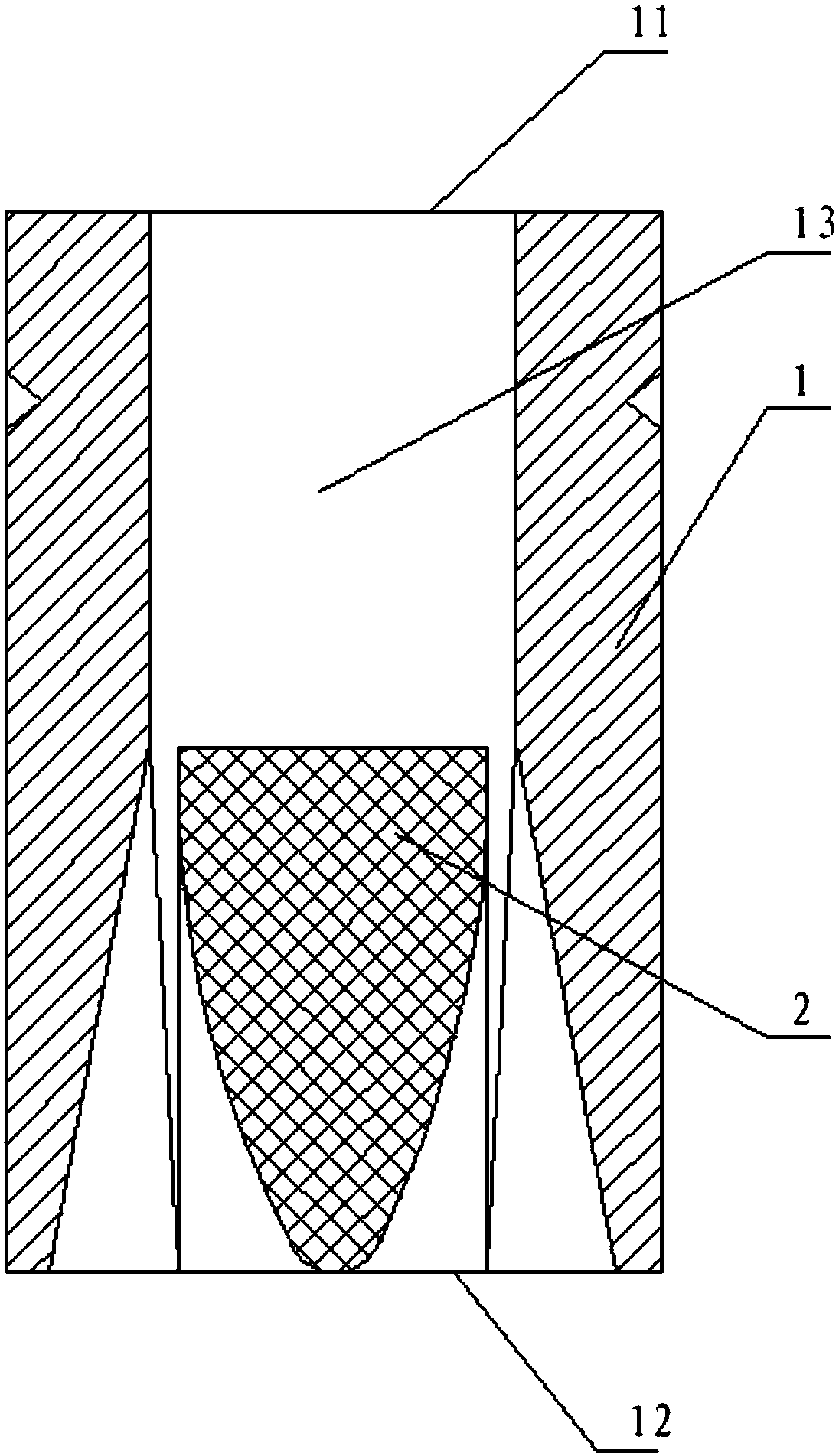

[0029] like Figure 1-2 A special spunbond non-woven fabric separator and spinner as shown, comprising a casing 1 and a shunt plug 2;

[0030] A gradual fluid channel 13 is formed inside the casing 1 from the inlet 11 end to the outlet 12 end;

[0031] The diverter plug 2 is disposed at the inner channel 13 at the end of the outlet 12 , and the cross-sectional area of the diverter plug 2 gradually increases from the end of the outlet 12 to the end of the inlet 11 , and the diverter plug 2 is streamlined.

[0032] Further, the cross-section of the inner wall at the end of the inlet 11 is circular, and the cross-section of the inner wall at the end of the outlet 12 is a U-shaped or V-shaped ring.

[0033] Further, the cross section of the inner wall at the end of the outlet 12 is an irregular and smooth shape such as an ellipse, a rectangle with rounded corners, and the like.

[0034] Further, the diverter plug 2 is streamlined. The internal channel 13 and the shunt plug 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com