Vibration isolator in floating slab track system and method for determining operating parameters of vibration isolator

A floating plate and vibration isolator technology, applied in the direction of tracks, roads, buildings, etc., can solve the problems of low natural frequency, impact of vibration isolation efficiency, rebound rise and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

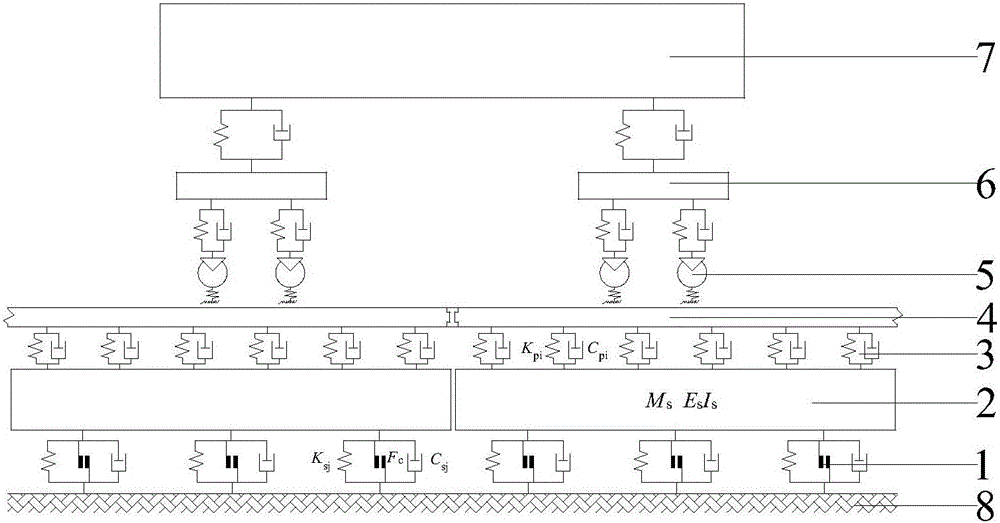

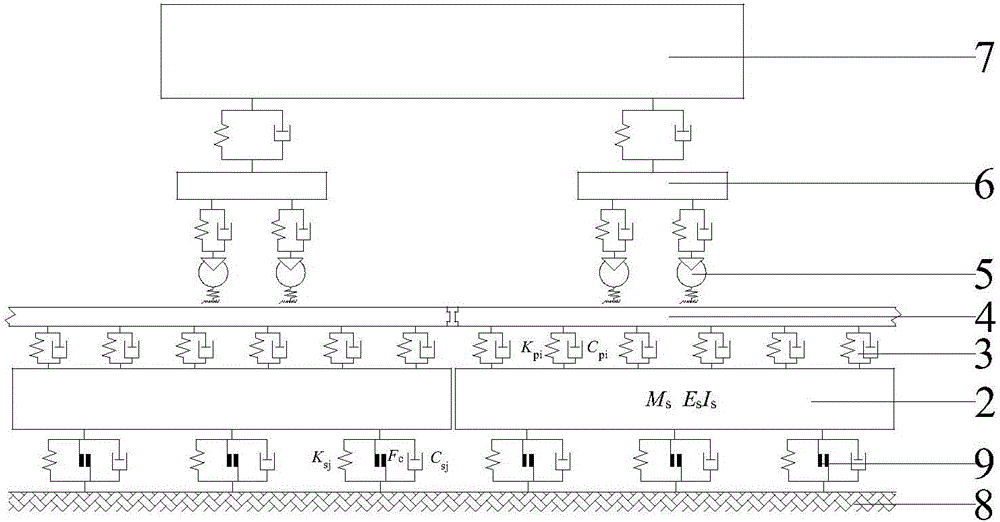

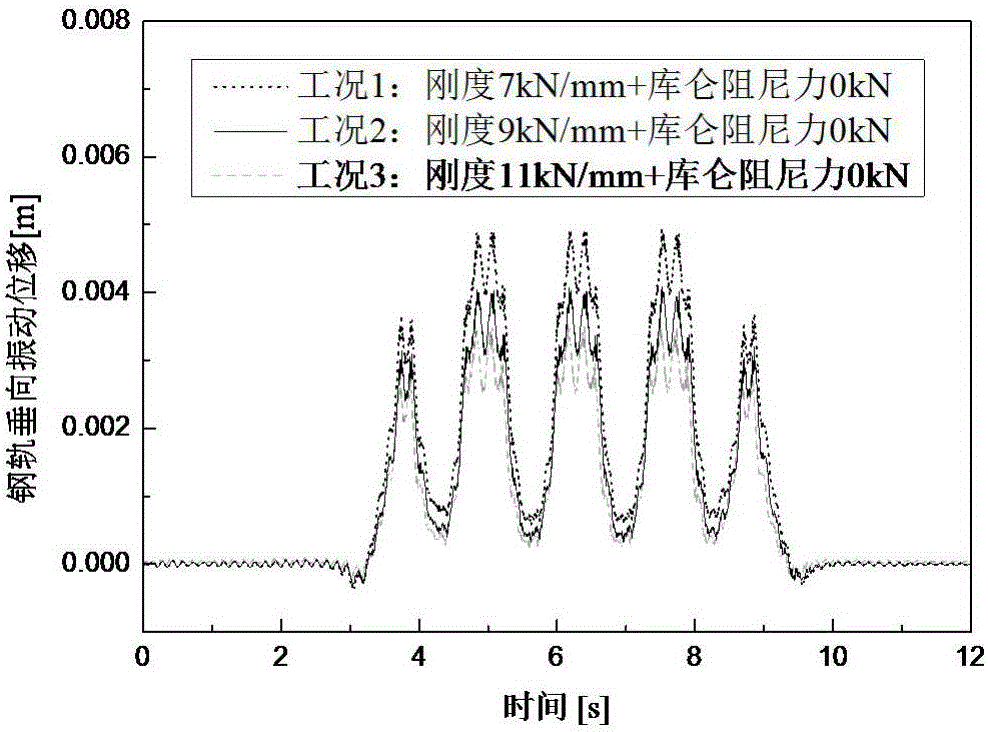

[0066] Implementation case: Taking the common steel spring floating slab track structure type in subway lines as an example, according to the method for determining the working parameters of the vibration isolator in the floating slab track system proposed by the present invention, carry out subway vehicle-controllable Coulomb damping floating Numerical simulation of the dynamic time-domain model of the slab-track coupling system, and a comparative analysis with the dynamic response of the steel spring floating slab track without Coulomb damping, to verify the feasibility and rationality of the design method for the controllable Coulomb damping working mode in the floating slab track sex.

[0067] The specific calculation conditions for the numerical simulation analysis are that the car body 7 is a type A subway car with a speed of 60km / h; the track structure includes a 60kg / m rail 4 and a rail fastener 3 (the dynamic stiffness coefficient is 60kN / mm, and the damping coefficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com