Light steel slope roof foundation layer dry tile hanging structure and construction method of changing plane roof into slope roof

A technology of sloping roof and tile structure, which is applied in the direction of roof covering layer, roof, roof using tile/slate tile, etc., can solve the problems of easy falling of tiles, increase of construction cost, unfavorable green construction and environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

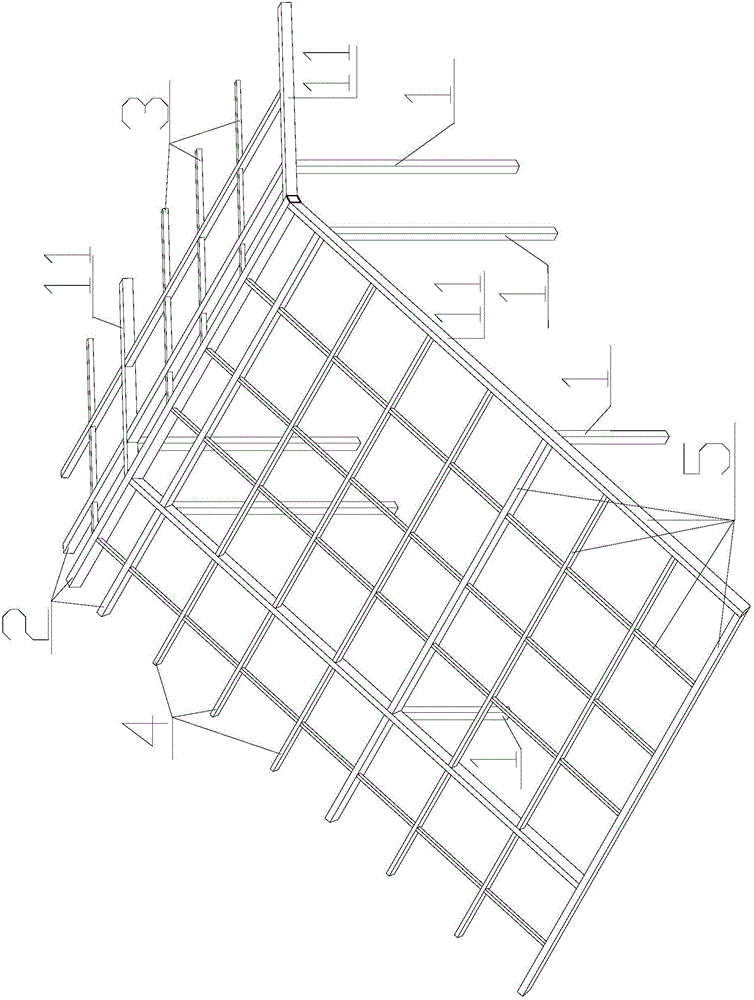

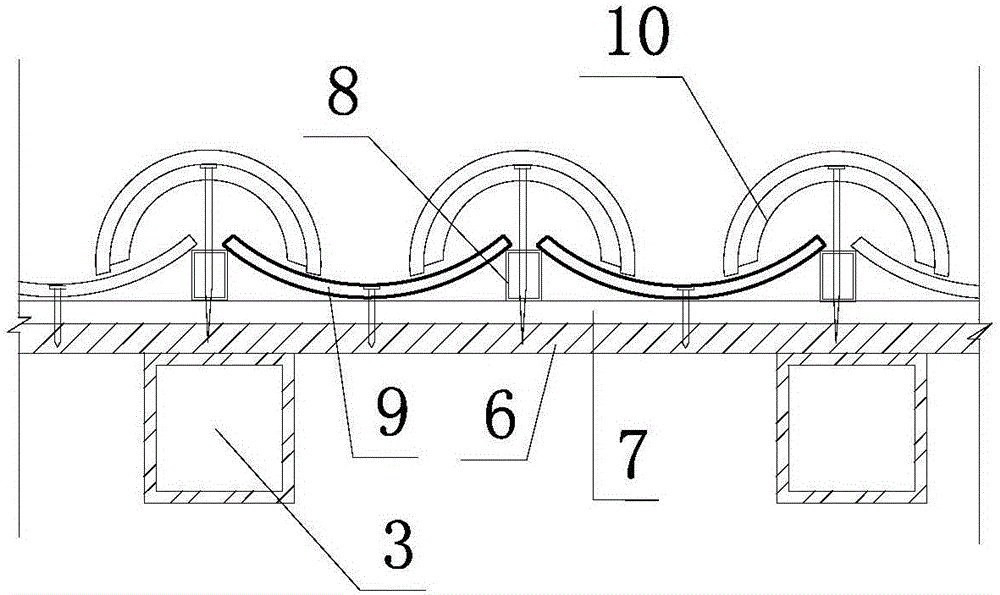

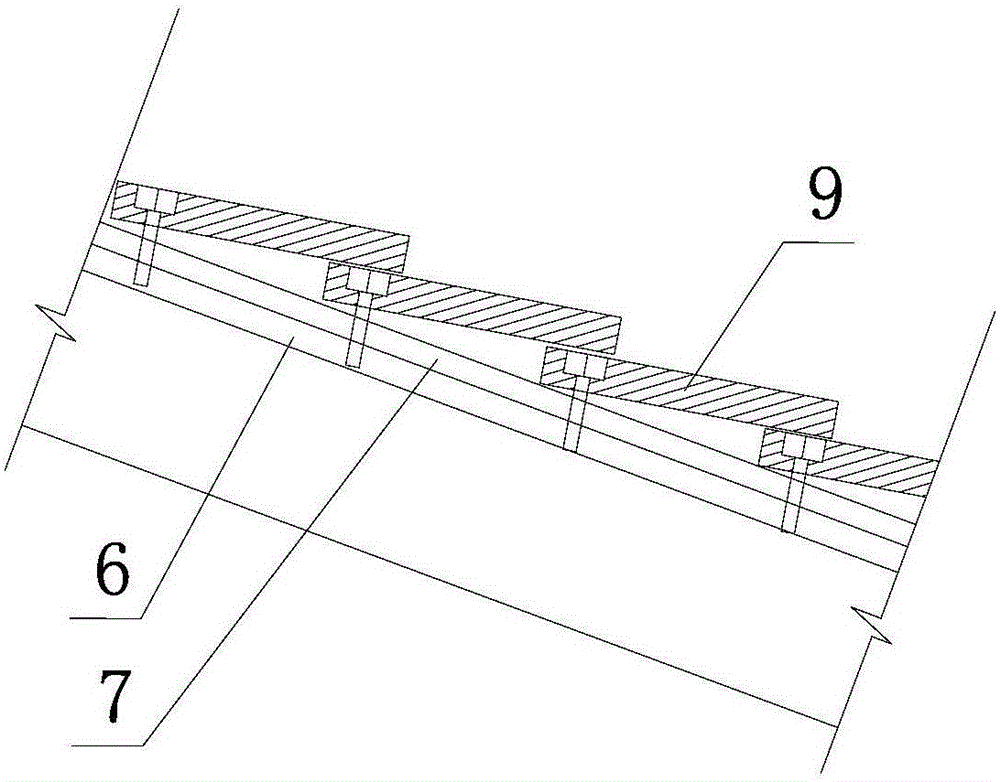

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the light steel sloping roof base dry-hanging tile structure of the present invention includes a light steel sloping roof base 5 composed of a horizontal main beam 2, an oblique main beam 11, a horizontal secondary beam 4 and an oblique connecting beam 3. And a plurality of columns supporting the base 5 of the light steel sloping roof. For the convenience of expression, first unify a concept, the horizontal direction refers to the direction parallel to the roof ridge, and the oblique direction refers to the direction perpendicular to the roof ridge, that is, the width direction of the roof. The upper surfaces of the connecting nodes of all horizontal main beams 2, oblique main beams 11, oblique connecting beams 3 and horizontal secondary beams 4 on the same ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com