a glass lifter

A glass lifter and slider technology, applied in the field of body accessories and glass lifters, can solve the problems of large friction between the lifter slider and the guide rail, affecting the service life of the slider, air drying or inhaling dust, etc., so as to improve the service life. , The effect of reducing the wear speed and reducing the friction force of the movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

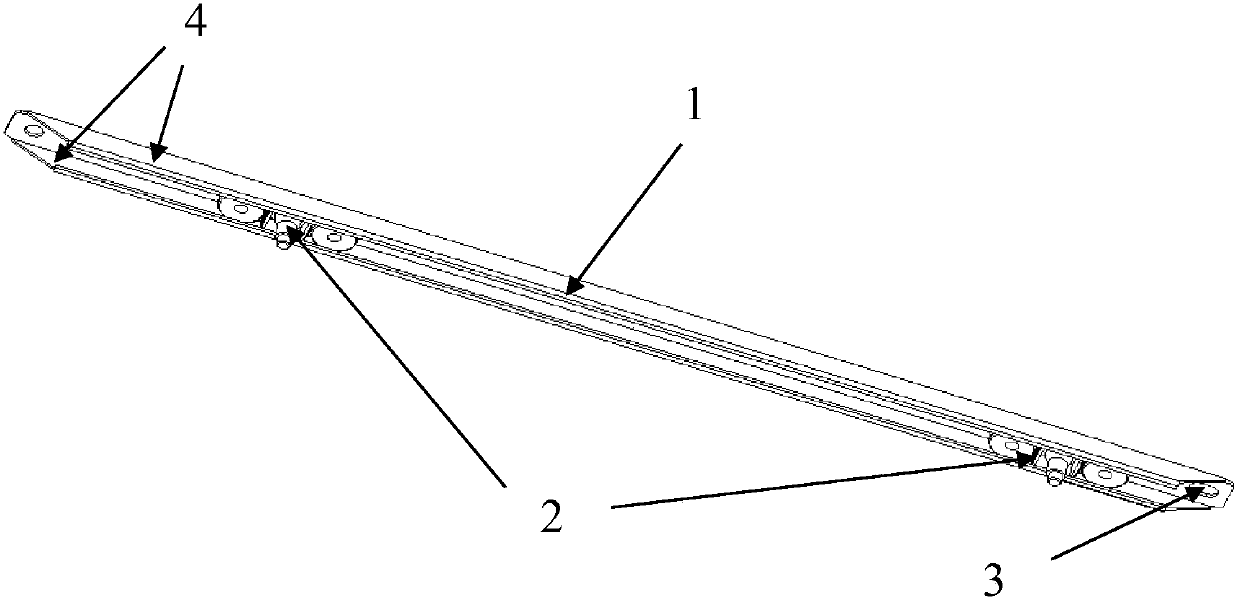

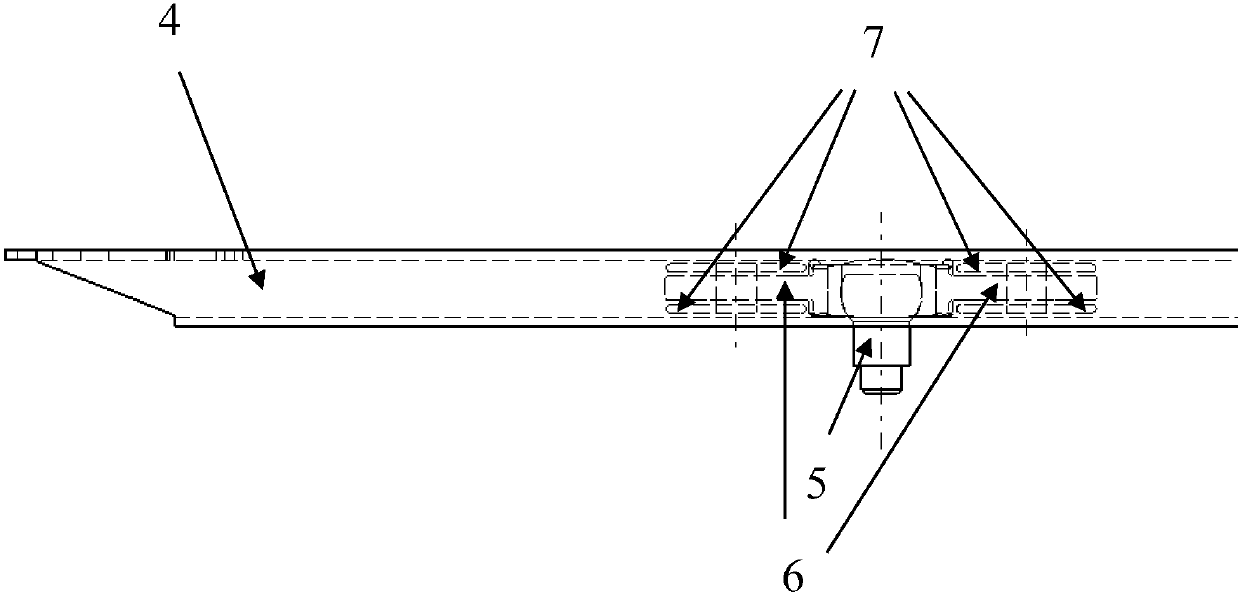

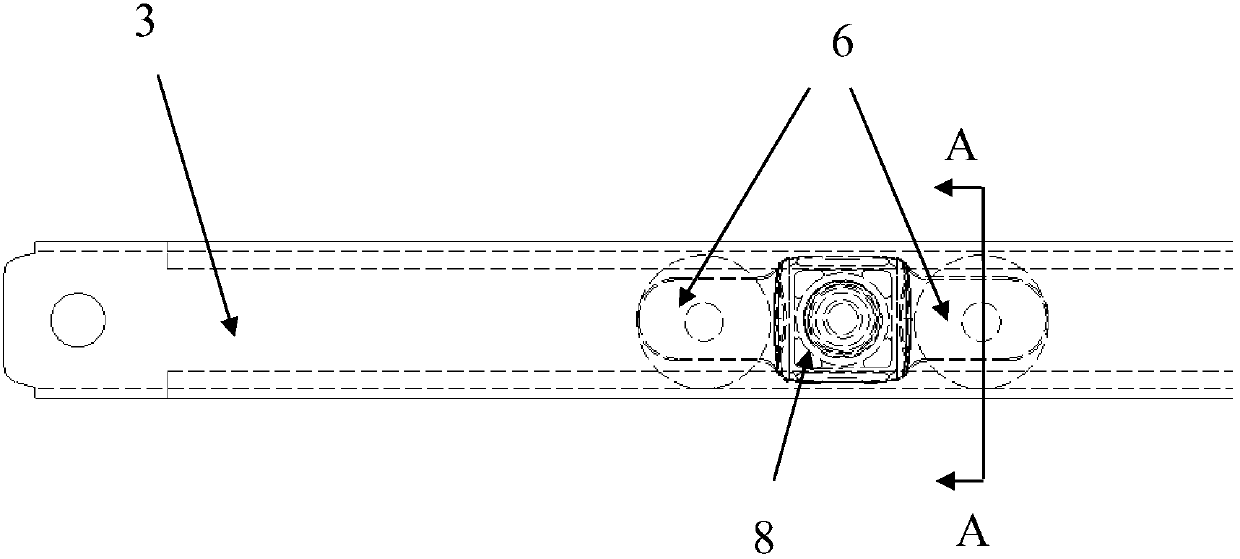

[0024] The glass regulator of the present invention, such as figure 1 , 2 , 3, including the guide rail 1 and the slider 2 located in the guide rail 1. The guide rail 1 is a long groove-shaped guide rail composed of the first guide surface 3 and the second guide surface 4 arranged on both sides of the first guide surface 3. The cross section is similar to a C-shaped structure; the slider 2 includes The contacting slider body 8 and the guide wheel 7 correspondingly contacting with the second guide surface 4 , the slider is connected with the lifting mechanism through the connecting shaft 5 . The structure of the new glass regulator changes the contact mode between the traditional slider and the guide rail. Through the horizontal and vertical guide rails and the cooperation with the slider body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com