Pressure relief method capable of satisfying parallel operation of tunneling and pressure relieving

A technology of parallel operation and pressure relief holes, which is applied in earthwork drilling, ground mining, mining equipment, etc., can solve the problems affecting the excavation efficiency and prolong the completion time of excavation projects, and achieve the effect of improving tunnel excavation efficiency and increasing excavation footage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

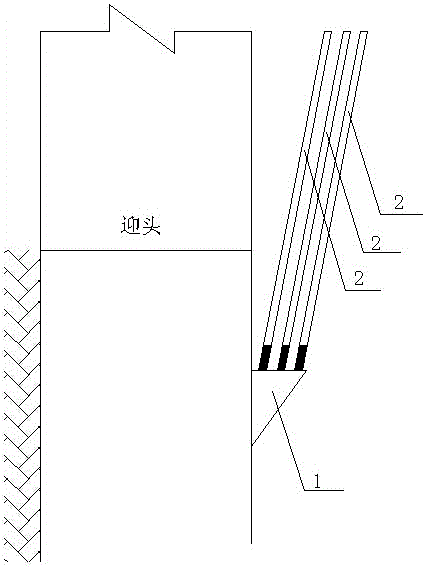

[0018] Below in conjunction with accompanying drawing this design is described in detail:

[0019] see figure 1 : a kind of step that can satisfy the pressure relief method of digging and unloading parallel operation comprises:

[0020] 1) Construction drilling site: a triangular drilling site 1 is constructed on the right side of the excavation roadway. The height of the drilling site 1 is consistent with the height of the roadway. The length of the side of the drilling site 1 connected with the roadway is 7m, and the other side is parallel to the head The length is 5m, and the length of the third side is 9m;

[0021] 2) Fix the drilling rig: move the high-power deep-hole hydraulic drilling rig to the drilling site 1, and the model of the high-power deep-hole hydraulic drilling rig 2 is ZDY4000LR; fix the drilling rig in the drilling site 1, adjust the drilling position and height of the drilling machine, and the drilling position and The included angle on the right side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com