Method for constructing super-shallow-burial subway station under transverse canopy erected inside micro pilot tunnel

A technology of subway station, shallow burial and underground excavation, which is applied in underground chambers, earthwork drilling, wellbore lining, etc. Low efficiency and other problems, to achieve the effect of simplifying the jacking process and jacking equipment, avoiding breaking the road surface modification pipeline, and reducing the section size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

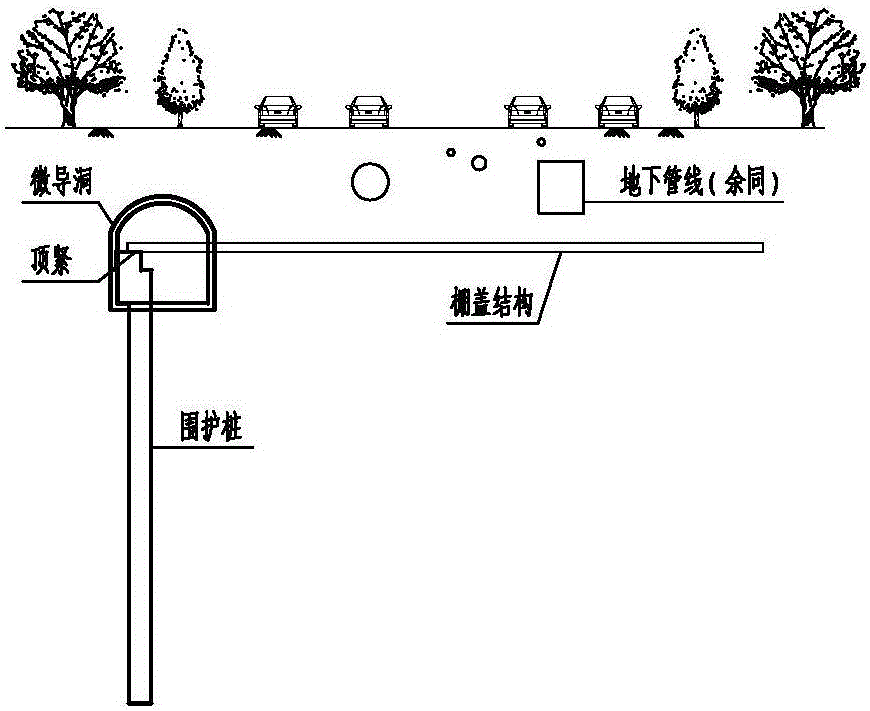

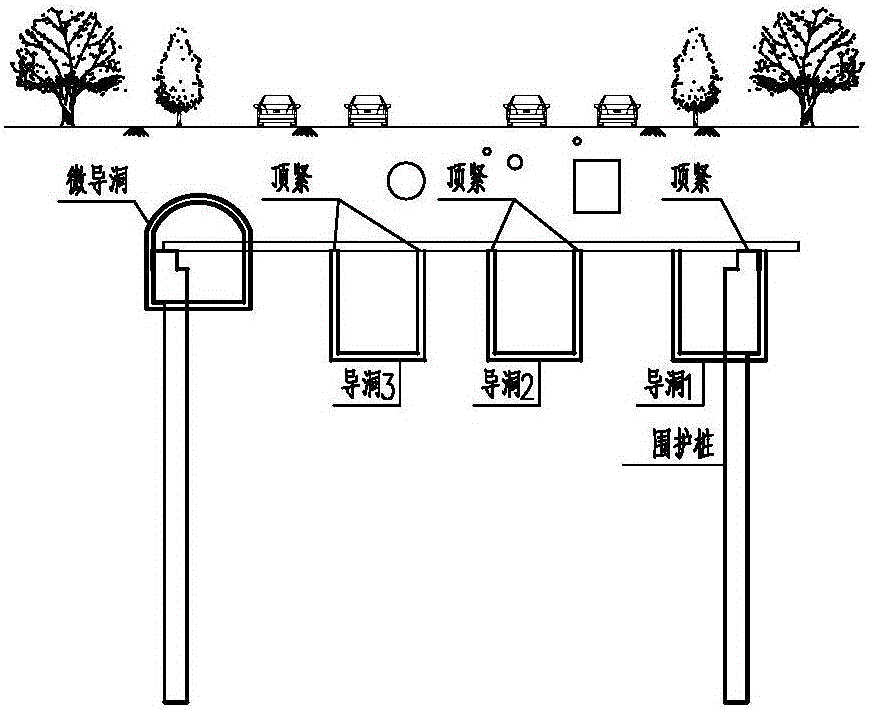

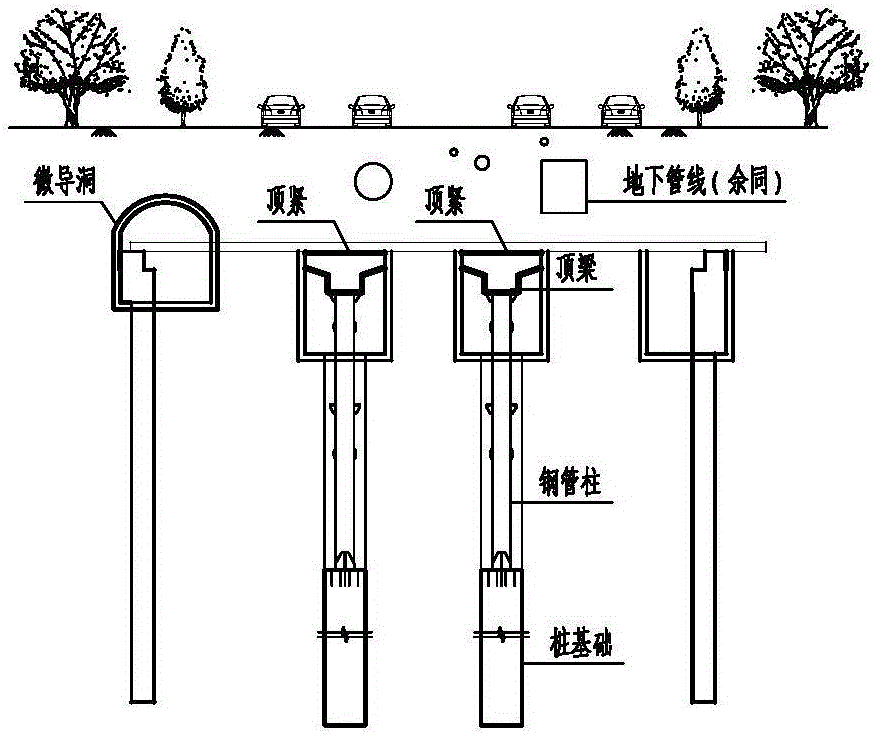

[0052] Construction method of ultra-shallow underground excavation subway station under horizontal shed cover in micro-pilot tunnel—shelf cover inversion method is a construction method for ultra-shallow buried flat-roof large-scale subway station structure under underground excavation, and it is also suitable for underground excavation For the excavation of other long strip-shaped large-scale underground space structures, the specific implementation methods are as follows:

[0053] see figure 1 Shown: The construction shaft and cross channel structure are excavated through the green space beside the road, the parking lot and other available sites, and the micro pilot tunnel structure is excavated by the cross channel, and the covering soil of the micro pilot tunnel is controlled at about 3m. After the excavation of the micro-pilot structure is completed, the enclosure piles to withstand horizontal and vertical forces will be constructed in the micro-pilot, and then the "shed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com