Assembly type movable machine frame easy to detach and assemble

A movable frame and assembled technology, which is applied in the direction of mechanical equipment, linear motion bearings, bearings, etc., can solve the problems of thin structure, difficult to disassemble freely, and occupy a large space, so as to achieve simple and reasonable device structure design, easy operation and Easy to disassemble and take up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

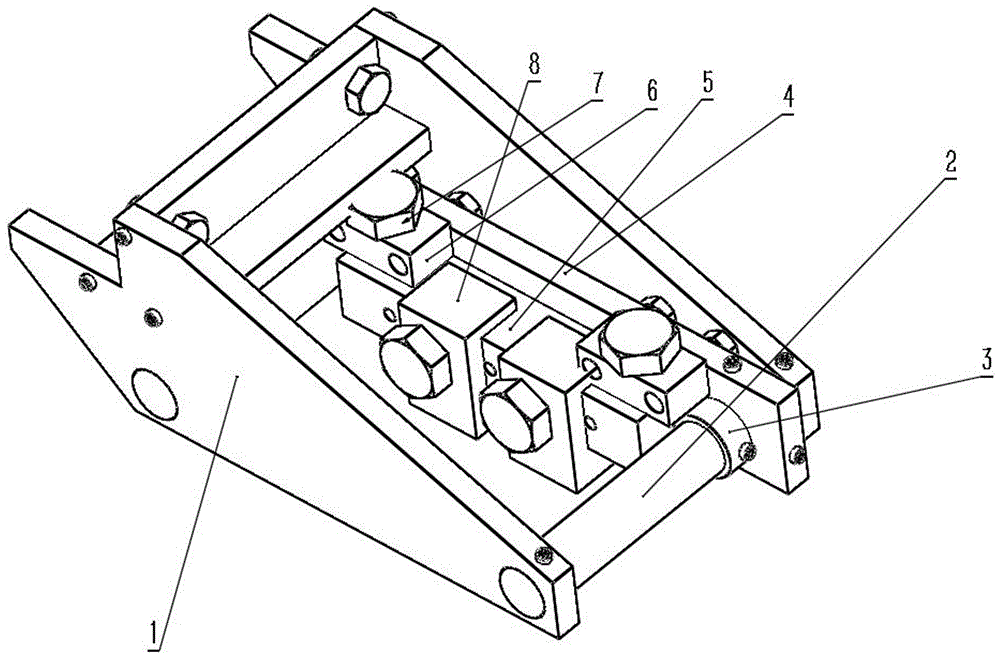

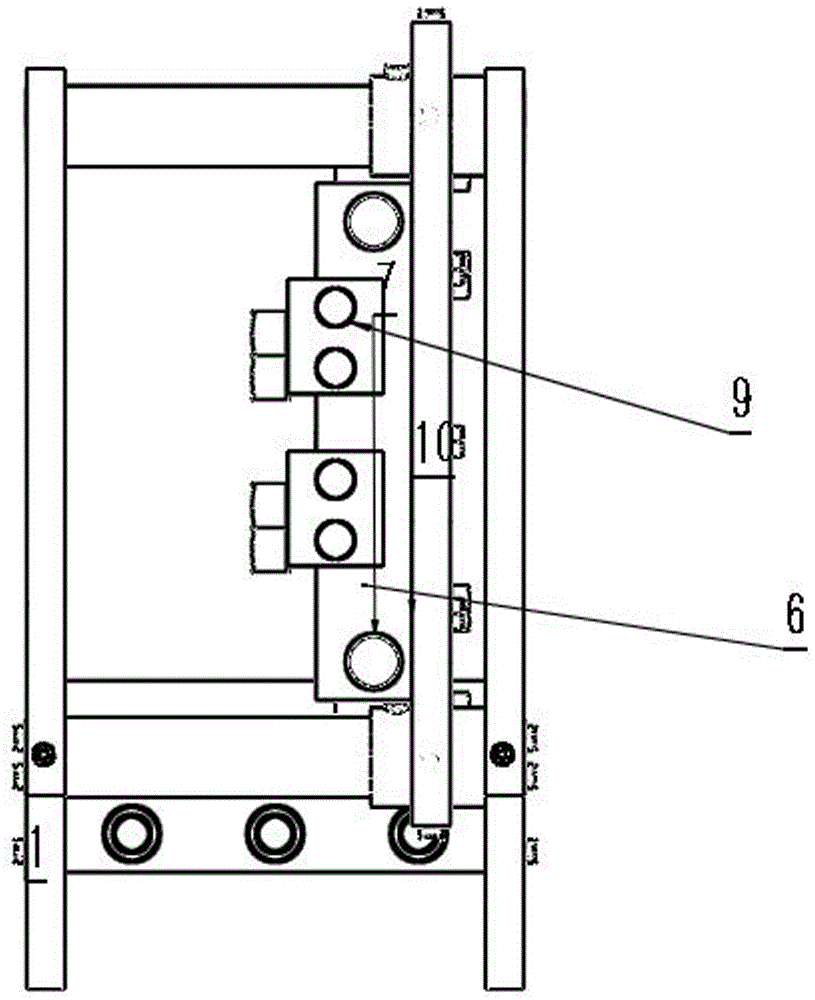

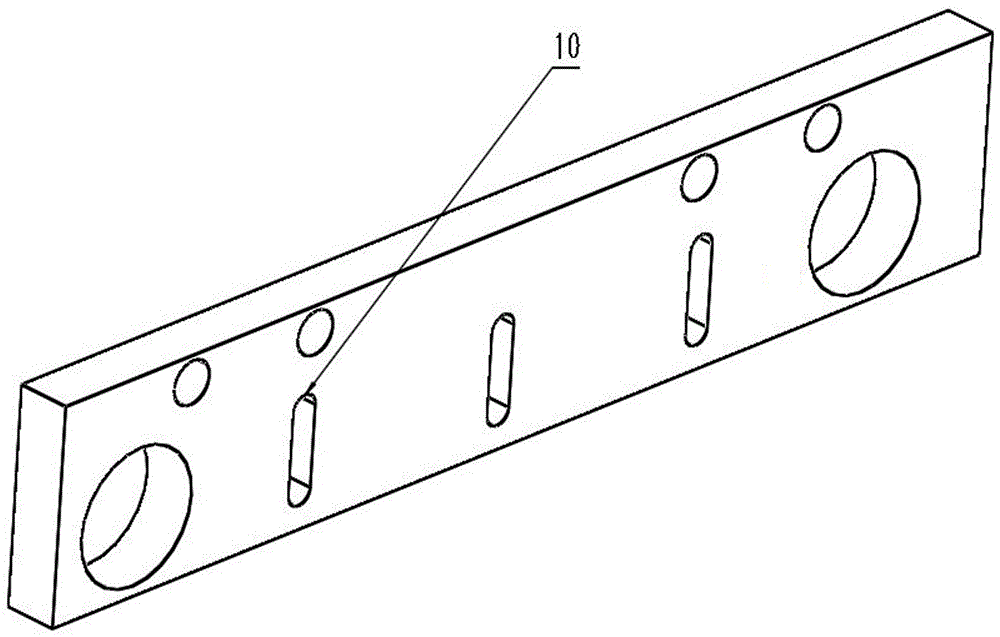

[0020] Such as figure 1 , 2 As shown, an easily disassembled assembled movable frame includes a fixed seat 1, a rotating shaft 2, a shaft sleeve 3, a support rod 4, a movable rod 5, a positioning bearing 6, a screw assembly 7, and a positioning groove 8. The fixed A pair of rotating shafts 2 are inserted into the through holes on both sides of the seat 1 and fixed with set screws. The shaft sleeve 3 is sleeved on the shaft 2 and fixed with set screws. The support rod 4 is inserted into the outside of the shaft sleeve 3 and fixed with set screws. , the support rod 4 is bolted to the movable rod 5, and the upper end of the supported rod 4 is bolted to fix two positioning bearings 6, and the positioning bearing 6 is connected and fixed to the movable rod 5 by a screw rod 11, and the movable rod 5 Two locating slots 8 are fixed on the sides with bolts, and two th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap