Fully automatic ball bearing assembly machine with seat

A technology of outer spherical surface and ball bearings, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of difficulty in ensuring the mutual position, large amount of labor, and high labor intensity, so as to reduce labor intensity, reduce labor amount, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

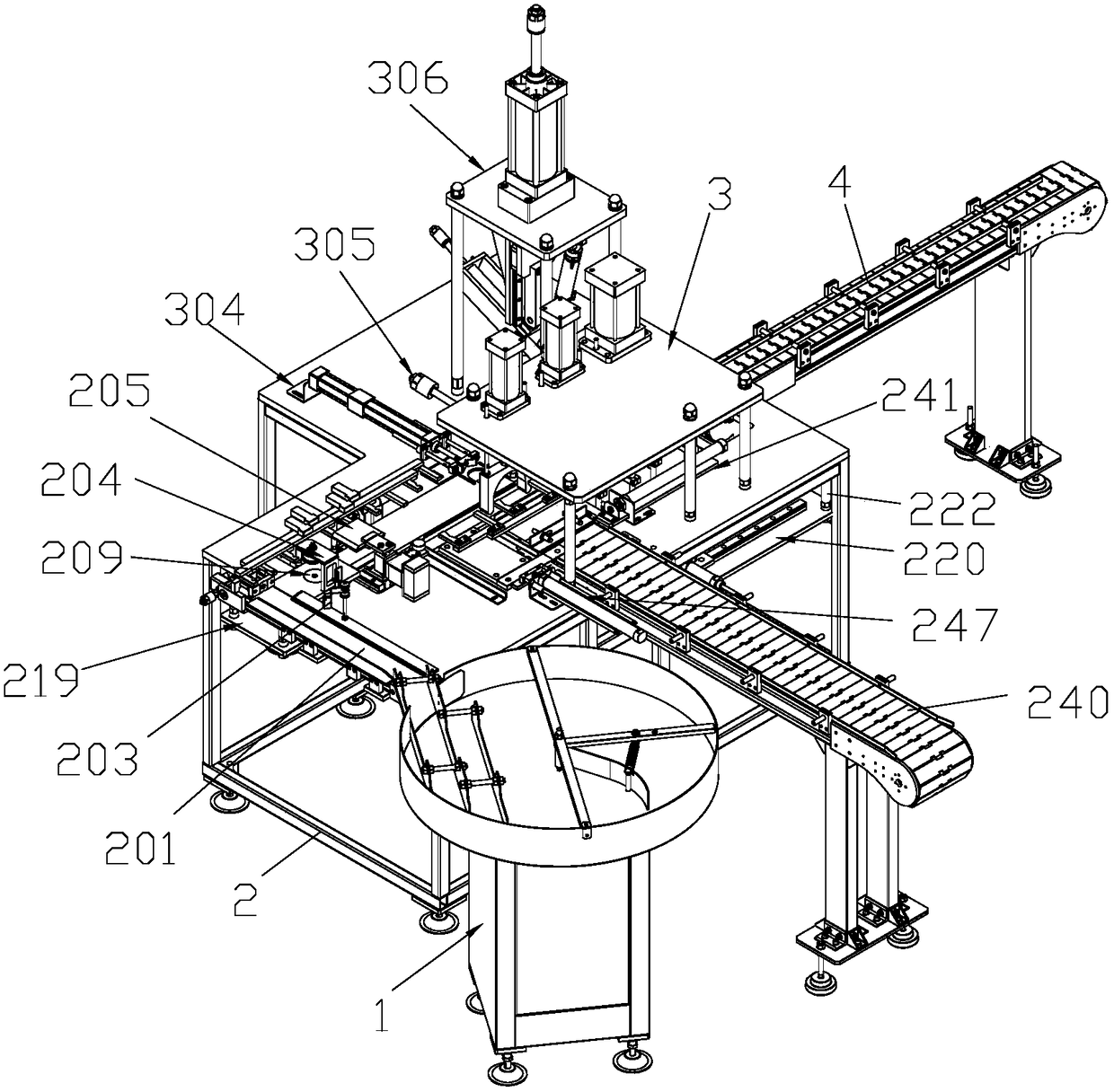

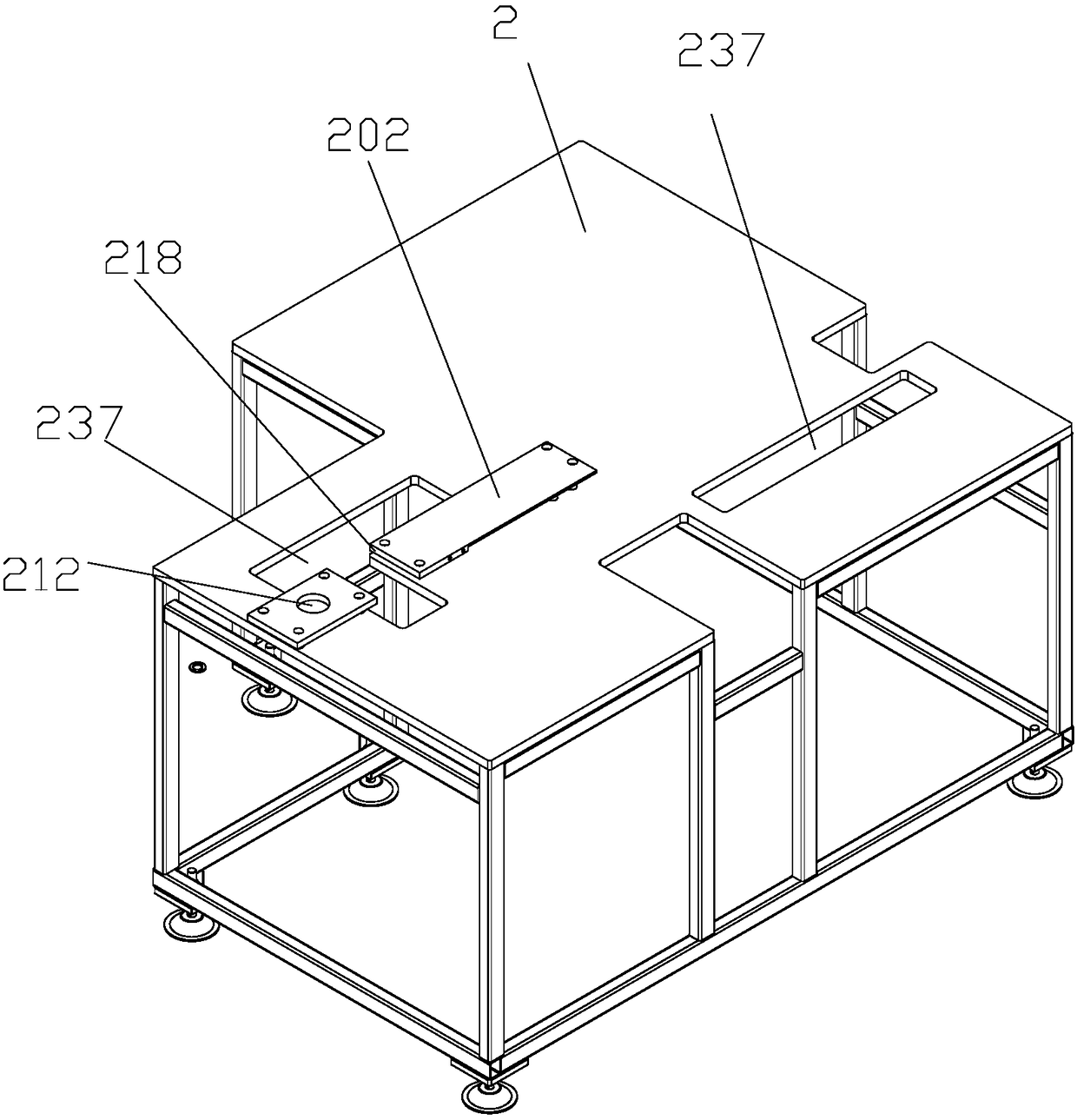

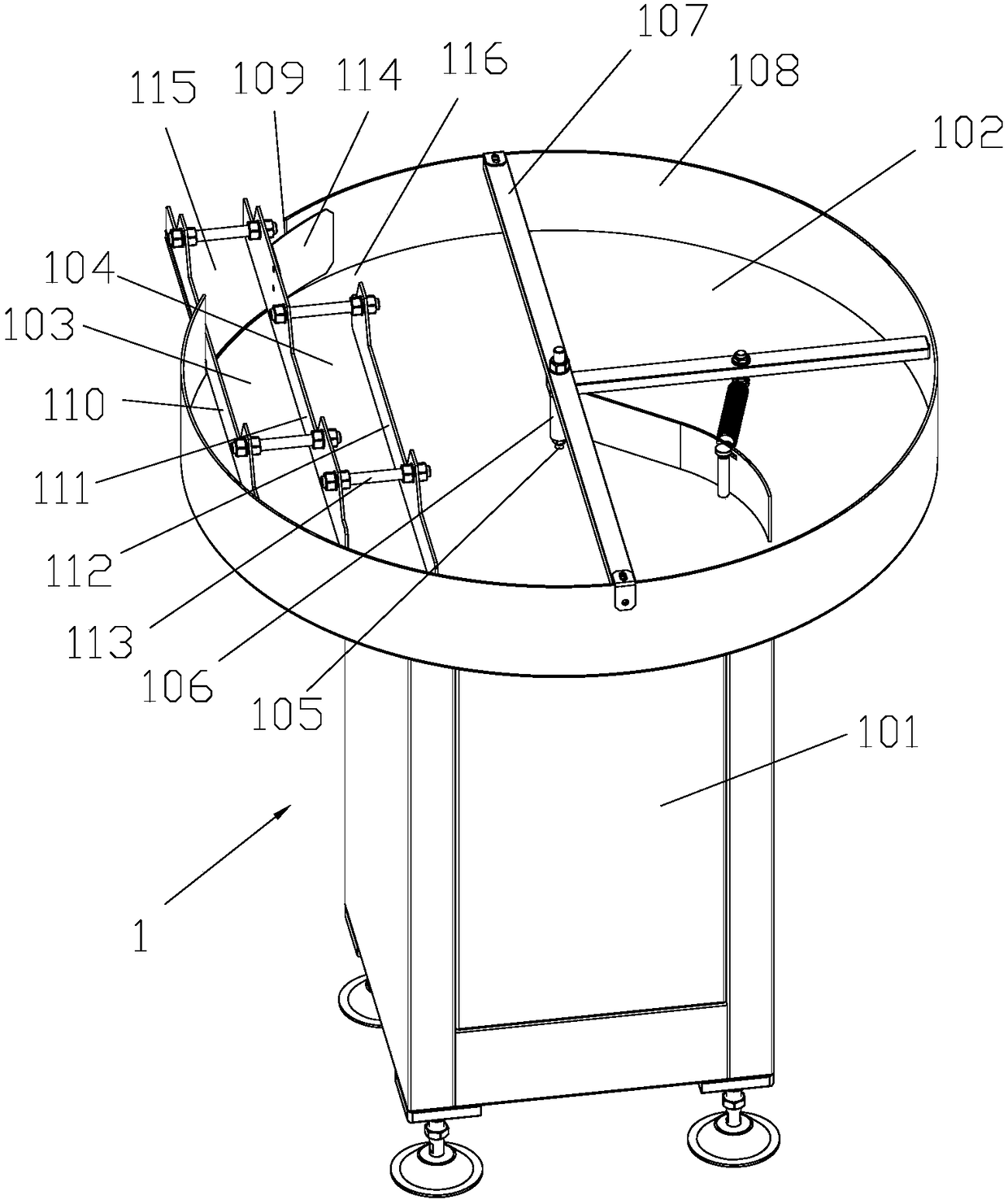

[0031] Such as Figure 1 to Figure 13 As shown, a fully automatic outer spherical ball bearing assembly machine with seat includes a feeding device 1, a frame 2 and a workbench 3, one end of the frame 2 is provided with a conveyor belt 201, and the feeding device 1 is connected to the conveyor The belt 201 is connected, and a supporting plate 202 is provided between the end of the conveying belt 201 and the workbench 3. The side wall of the conveying belt 201 is provided with an induction device 203, and the outer spherical ball bearing moves from the feeding device 1 to the conveying After the belt 201 is on, when the sensing device 203 does not sense the outer spherical ball bearing, the feeding device 1 works to deliver the outer spherical ball bearing to the conveyor belt 201, otherwise, the feeding device 1 stops operating, and the feeding device 1 The feeding device 1 includes a cabinet 101, a turntable 102, a feed channel 103 and a runner 104, the turntable 102 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com