Combined water level control valve without power source

A water level control, combined technology, applied in valve details, diaphragm valves, valve devices, etc., can solve the problems of easy to forget to turn off the water, labor and time consuming, water loss, etc., to achieve the effect of no power supply, sensitive response, and clever design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further illustrate the present invention, it is introduced below in conjunction with the description:

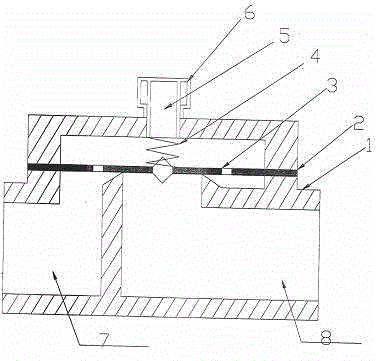

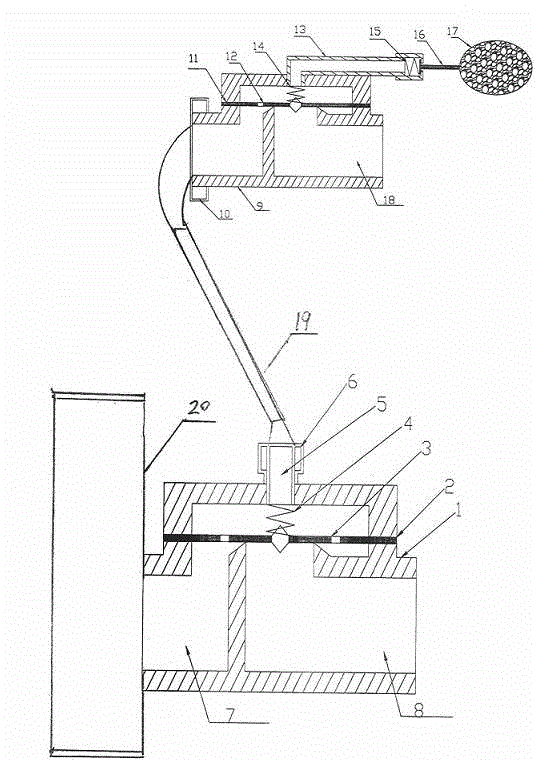

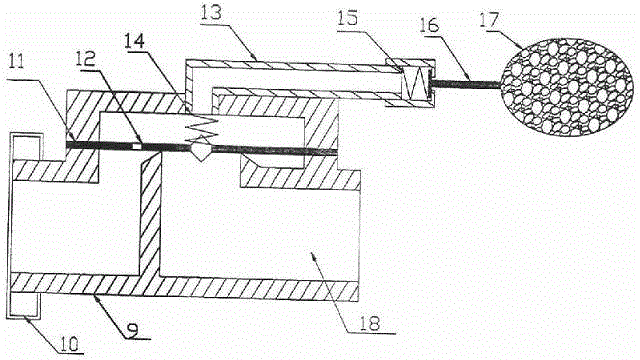

[0014] Refer to the attached figure 1 and figure 2 , image 3 , Combined water level control valve without power supply, the main valve includes valve body 1, diaphragm 2, equalizing pressure hole 3, return spring 4, pressure relief hole 5, union nut 6, water inlet 7, water outlet 8, secondary valve It includes valve body 9, union nut 10, die plate 11, pressure equalization hole 12, pressure relief conduit 13, return spring 14, pilot return spring 15, eccentric ejector rod 16, float 17, water outlet 18, connecting hose 19. In the inner cavity of the main valve 1, a diaphragm 2 is placed above the annular outlet. There are pressure equalization holes 3 on both sides of the diaphragm 2, and a return spring 4 is arranged in the hollow cavity between the diaphragm 2 and the valve cover. The center is provided with a pressure relief hole 5, a union nut 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com