Electric steamer and control method thereof

A control method and technology for an electric steamer, applied in the field of kitchen appliances, can solve problems such as waste of energy efficiency, inconvenient sterilization, etc., and achieve the effects of improving energy efficiency, ensuring water quality, and avoiding dry burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

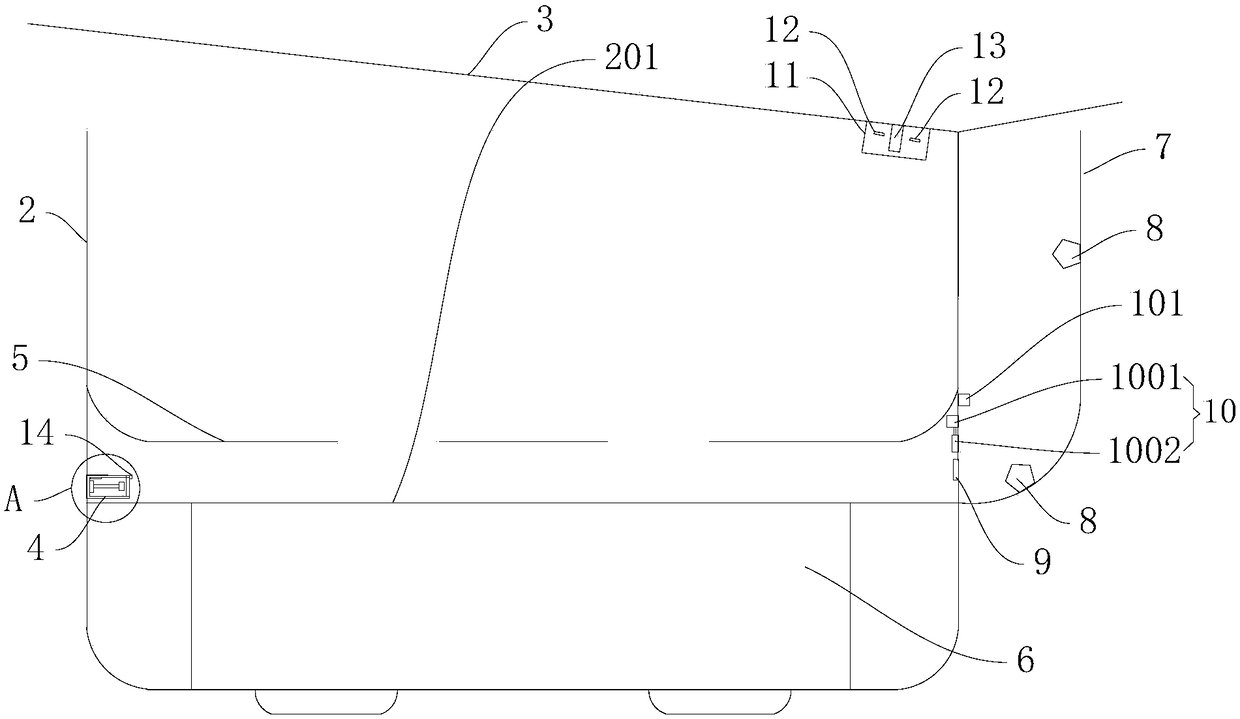

[0064] Further, as a specific implementation of the electric steamer control method provided in the present invention, when the wiper 11 and the second ultraviolet unit 12 are provided, the method further includes the following steps:

[0065] After the steaming is finished, the main control unit controls the second driving unit 13 to drive the wiper 11 to move to clean the pot cover 3, and at the same time controls the second ultraviolet unit 12 to emit light.

[0066] It can clean, disinfect and sterilize the remaining distilled water on the lid 3, prevent the wiper 11 from breeding bacteria, and prevent the water droplets on the lid 3 from contacting the bacteria that enter the air through the steam hole on the lid 3 quickly. It becomes a breeding ground for bacteria and prolongs the preservation time of food in the pot.

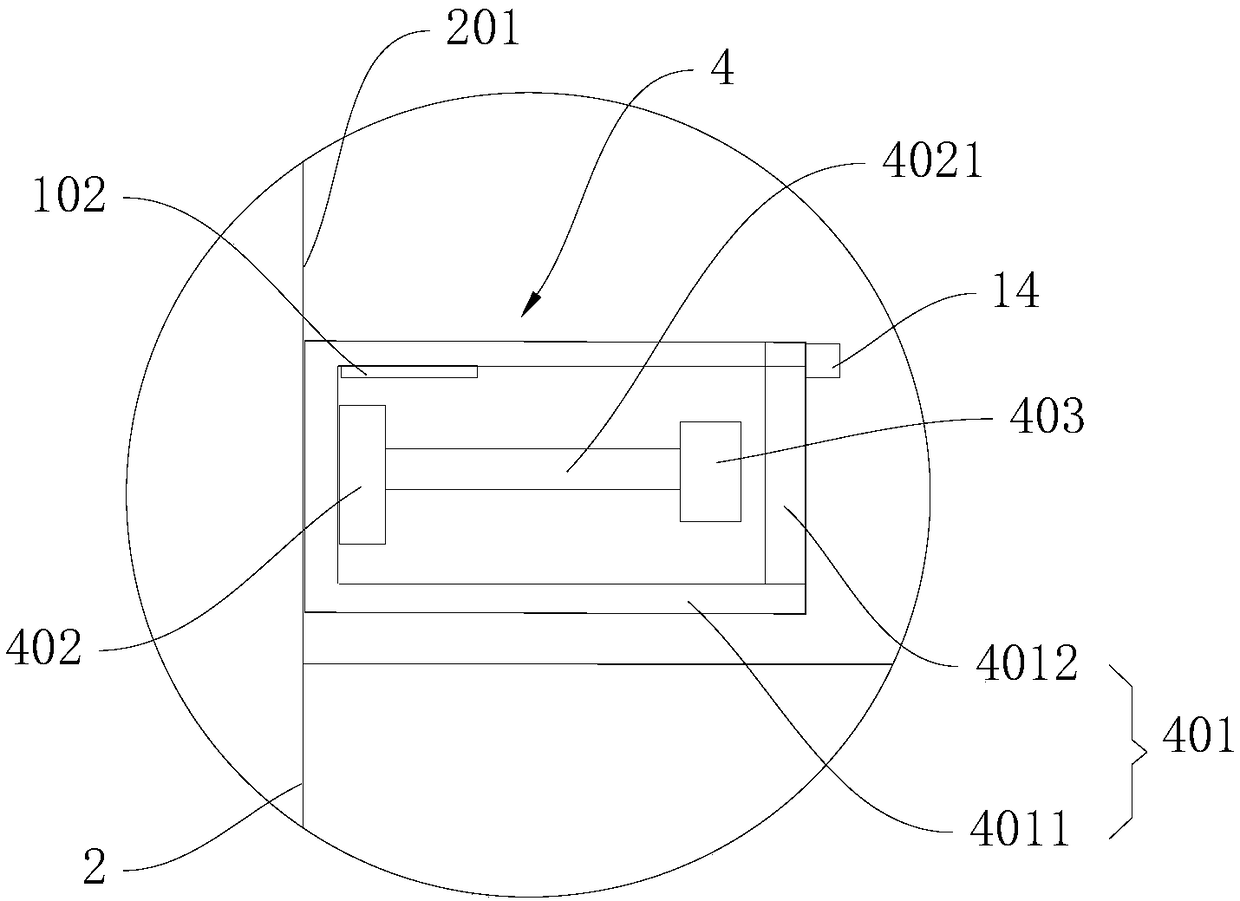

[0067] Specifically, when the first ultraviolet unit 8, the second ultraviolet unit 12, or the third ultraviolet unit 403 (if corresponding structures are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com