Connector for draining pipeline

A technology for drainage pipes and connectors, which is used in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc. It can solve the problems of cracks in the joints of corrugated pipes and no connectors yet, and avoid opening the mouth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

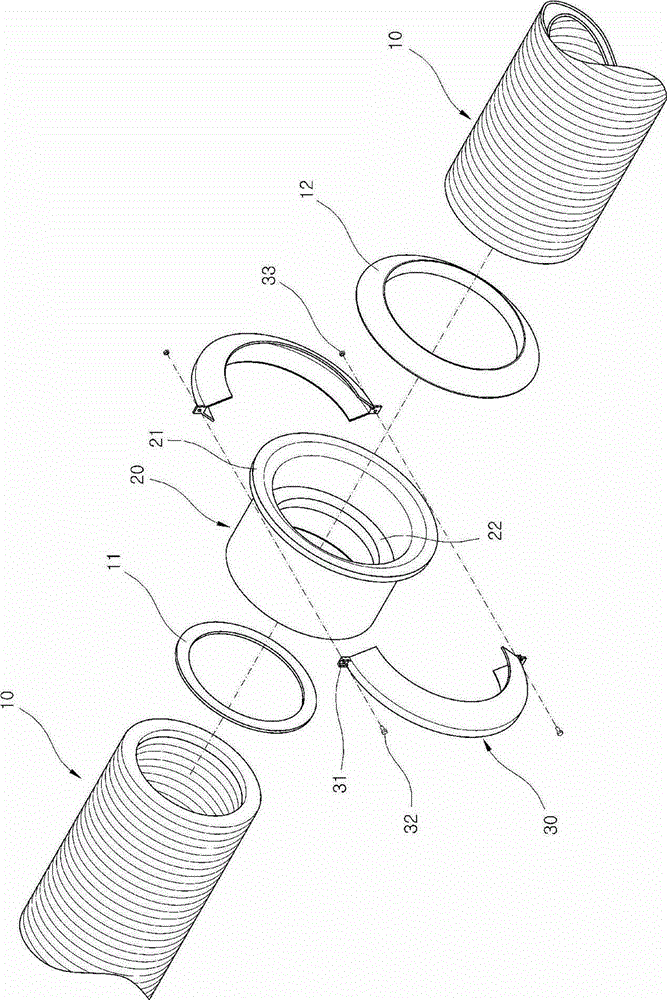

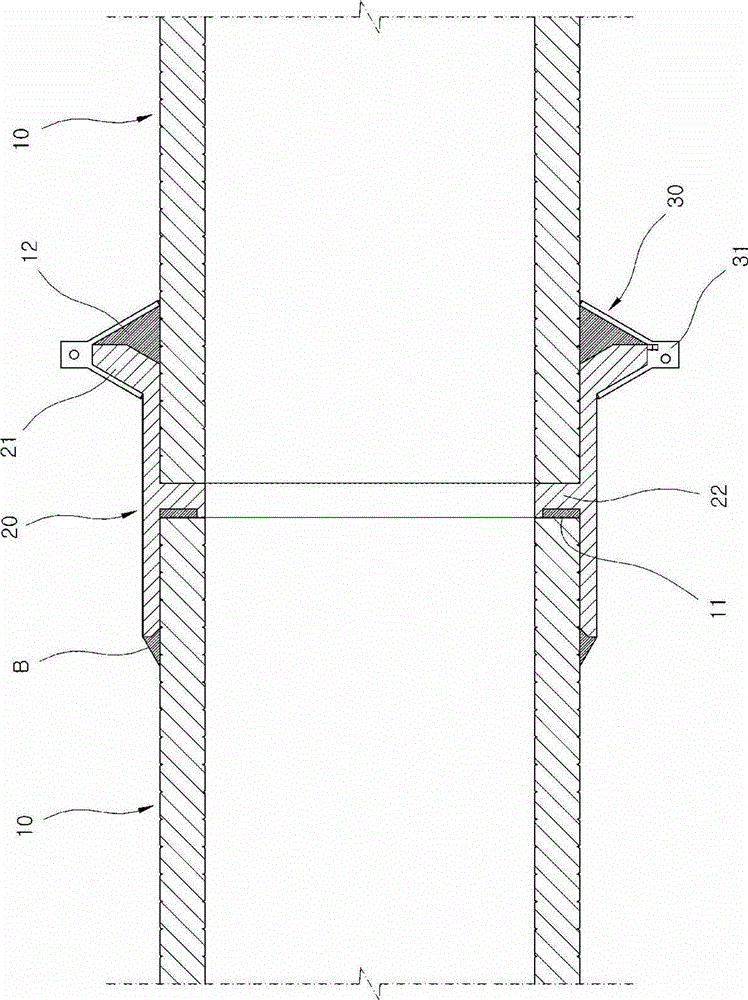

[0023] The reference signs in the drawings of the description include: collar 30, sleeve 20, ring block 22, flared end 21, rubber sealing ring 11, hot-melt belt B, bolt 32, nut 33, ear plate 31, ring body 12 .

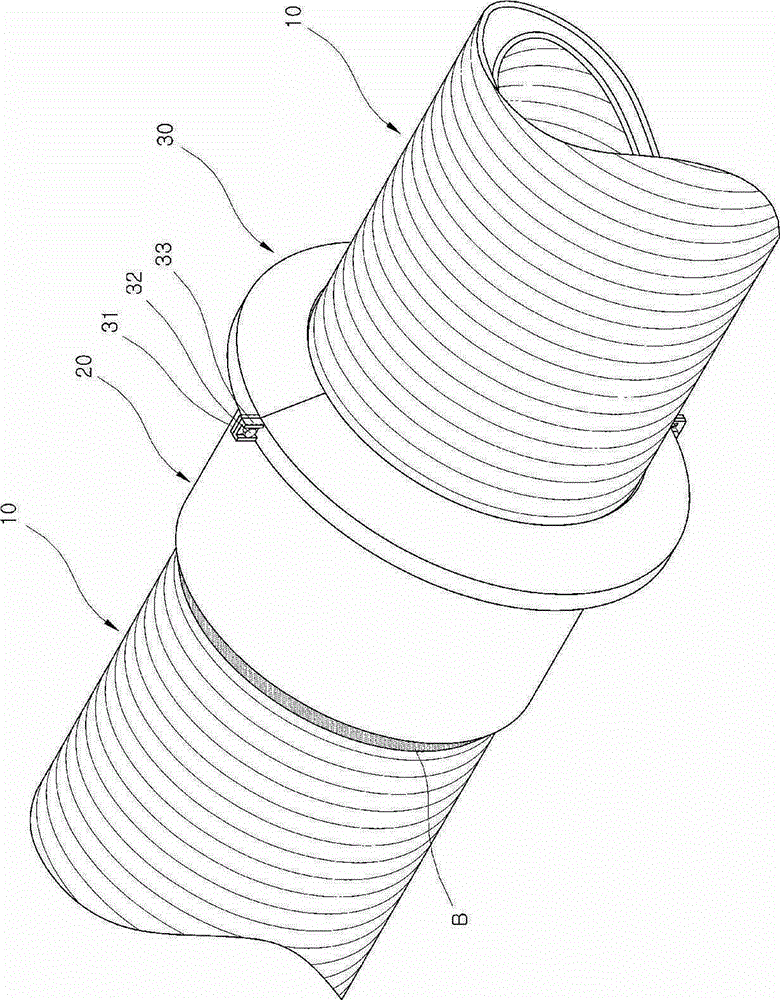

[0024] Such as figure 1 and figure 2 As shown, the drainage pipe connector of this embodiment is used for connecting at the junction of two spiral corrugated pipes. As is well known to the public, the outer wall of the threaded corrugated pipe is provided with several sections of corrugation, and the corrugations include indentations and protrusions.

[0025] The drainage pipe connector in this embodiment includes a sleeve 20, and the inner wall of the sleeve 20 is provided with an annular block 22, and the two sides of the annular block 22 are respectively used for docking with the corrugated pipe, and one end of the sleeve 20 is a flaring end 21; if figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com