Refrigerator with air cooling double-system

A refrigeration system and dual-cooling technology, which is applied in the direction of household refrigerators, coolers, household appliances, etc., can solve the problems of small volume in a single small space, inability to store food, uneven refrigeration, etc., and achieve compact structure, uniform refrigeration, and high performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

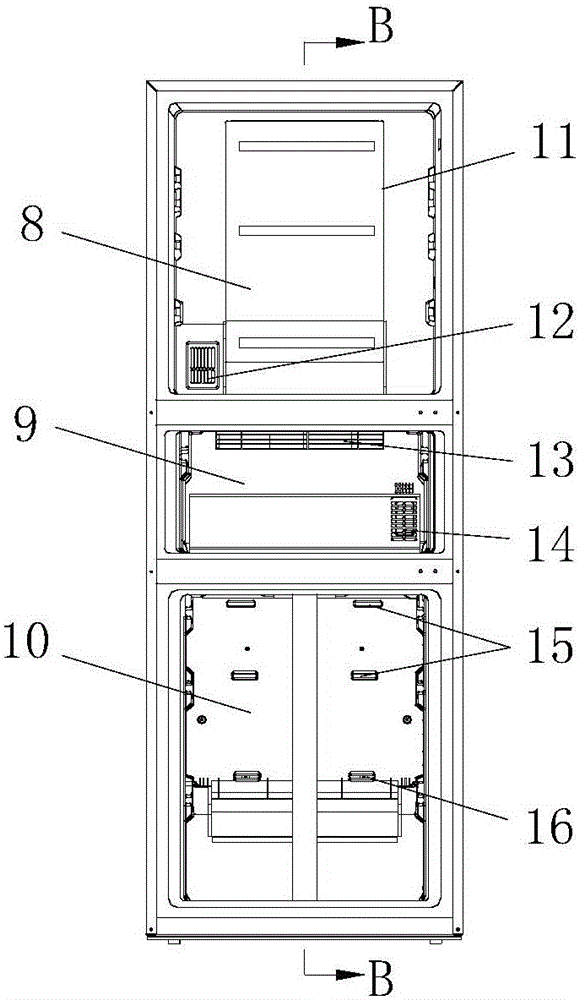

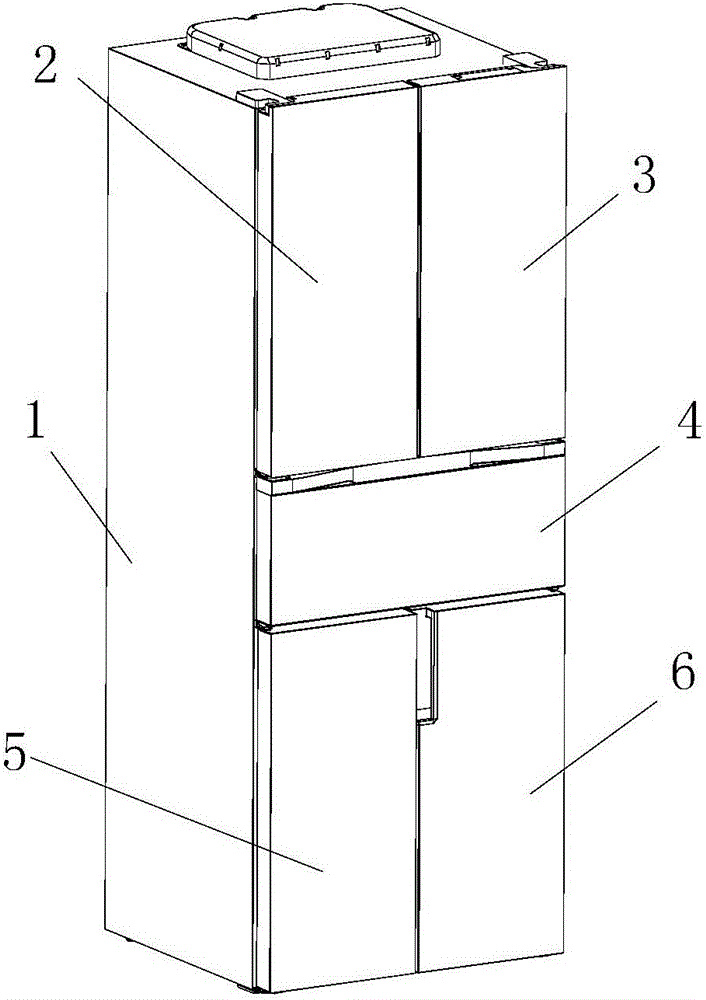

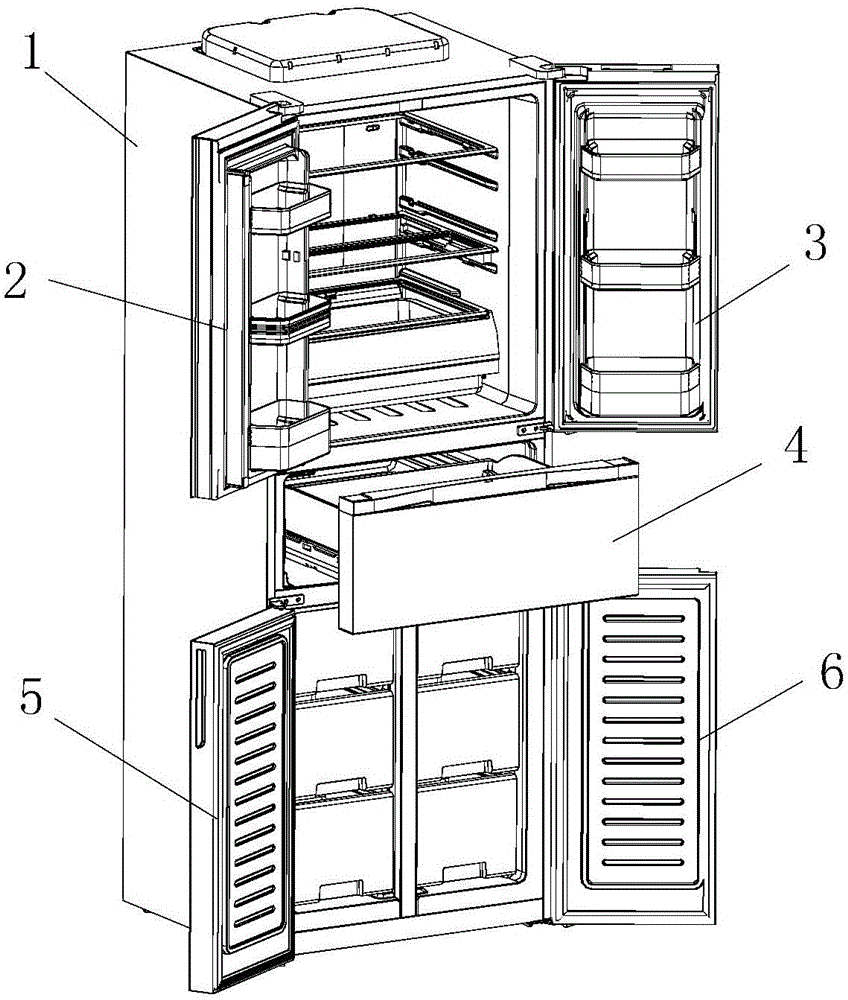

[0034] like Figure 1 to Figure 6 As shown, a refrigerator with dual air-cooling systems includes a box body 1, and the box body 1 is provided with a refrigerating zone 8, a temperature-variable zone 9 and a freezing zone 10. There is a temperature-changing room, and a freezing room is arranged in the freezing area 10. The temperature-changing room and the freezing room are integrally injection-molded, and a foam partition 20 is arranged between the changing room and the freezing room; the refrigerating area 8 is provided with two first The door bodies are the left door body 2 of the refrigerator and the right door body 3 of the refrigerator respectively. Both the left and right doors of the refrigerator are connected to the box body 1 in rotation, and the left and right doors of the refrigerator are of a split structure; the variable temperature zone 9 is provided with The variable temperature door body 4, the variable temperature door body 4 is a drawer type structure, and t...

Embodiment 2

[0037] like Figure 7 to Figure 9 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that: the temperature-changing room and the freezing room are injection-molded independently, and the foaming material 7 for integral injection molding of the box is between the changing room and the freezing room.

[0038] The parts not mentioned in the present invention can be realized by adopting or referring to the existing technology.

[0039] In addition, the terms "first" and "second" are used for descriptive purposes only, and should not be understood as indicating or implying relative importance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com