Test device and method for acquiring impact crater samples different in size and distribution at time

A test device, a one-time technology, applied in the direction of using a single impact force to test the strength of materials, measuring devices, sampling, etc., can solve the problems of high test cost and long cycle, achieve short test time, shorten test cycle, and reduce energy consumption and the effect of trial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

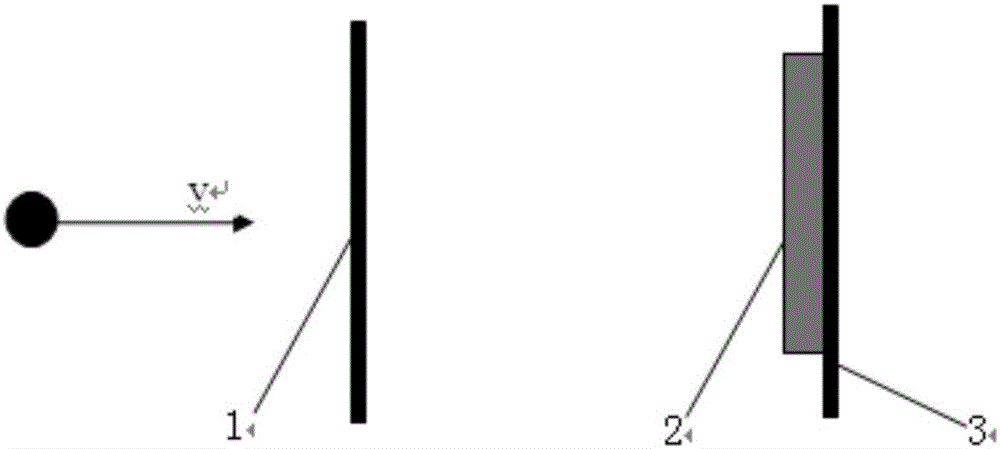

[0023] Embodiment 1: A test device for obtaining impact crater samples of different sizes and different distributions at one time, the device includes a vertical plate 1, a sample 2 and a vertical plate 2 3;

[0024] One side of the vertical plate 1 is facing the incident projectile, the other side is provided with the vertical plate 2 3, and the sample 2 is installed on the side of the vertical plate 2 3 facing the vertical plate 1, and the vertical plate 1 is relatively parallel to the vertical plate 2 3.

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that: the vertical plate 1 (priority) adopts an alloy plate, and the vertical plate 2 3 has the same order of magnitude of dynamic stiffness as the sample 2.

[0026] The vertical plate 23 plays the role of fixing the sample, and at the same time ensures that the pit forming process of the sample 2 is complete, and its dynamic stiffness should be close to that of the sample 2.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the number of samples 2 is 1-50.

[0028] The sample 2 can be single or multiple, and the shape and size of multiple samples 2 can be the same or different, and the shape of the sample 2 can be plate-shaped or other shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com