Particle spreading device based on measurement of flow field inside piv ventilated cavity

An internal flow field and particle technology, applied in measuring devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve problems such as blockage of ventilation pipelines, particle accumulation, and inability to use gas flow fields, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

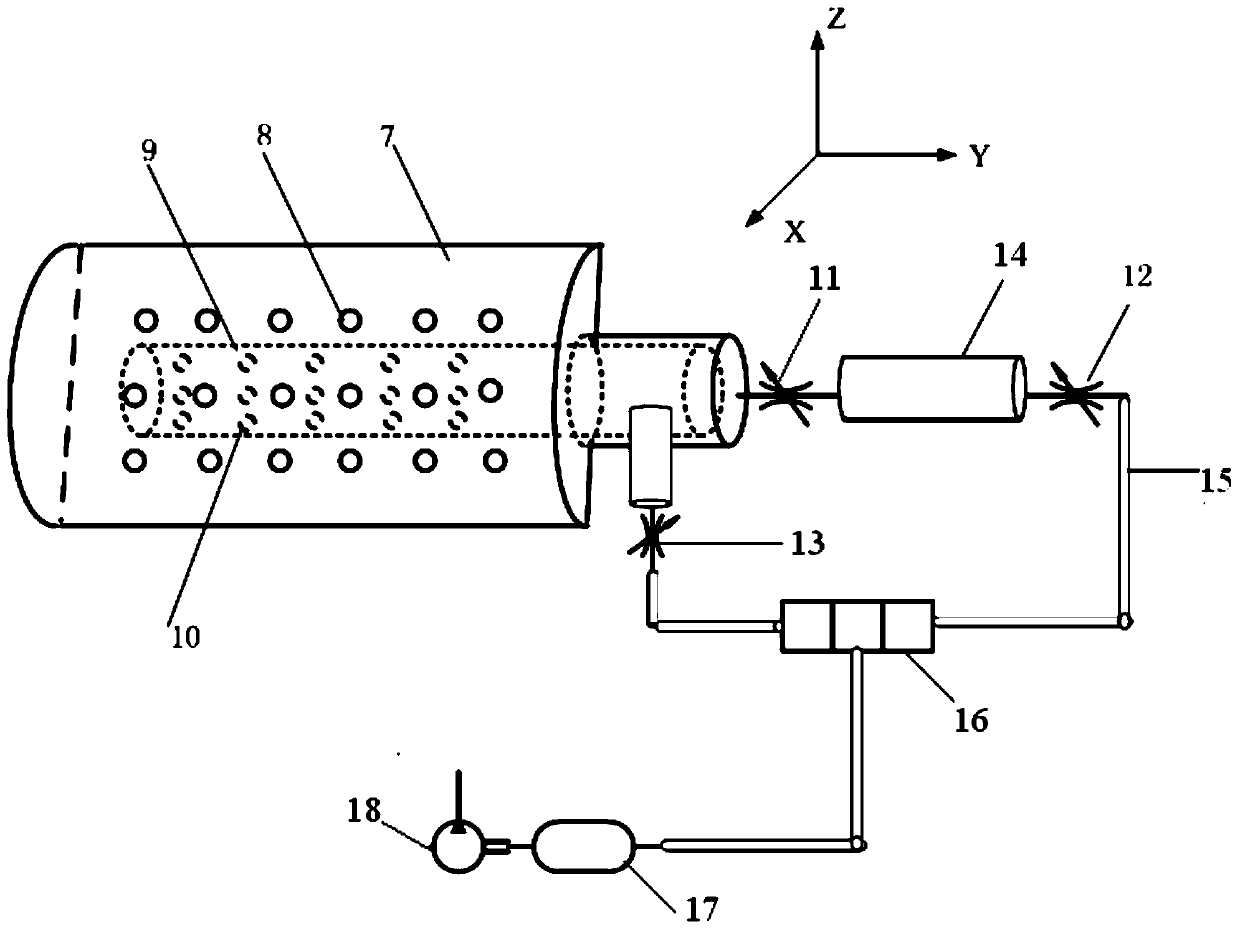

[0019] as attached figure 1 As shown, the present invention provides a particle spreading device based on the measurement of the internal flow field of the PIV ventilation cavity, the spreading device includes a cavitator 7, a particle storage pipe 14, a particle buffer pipe 9, a connecting pipe 15, and a three-way valve 16 , control valve Ⅰ11, control valve Ⅱ12, control valve Ⅲ13, gas storage tank 17 and air compressor 18;

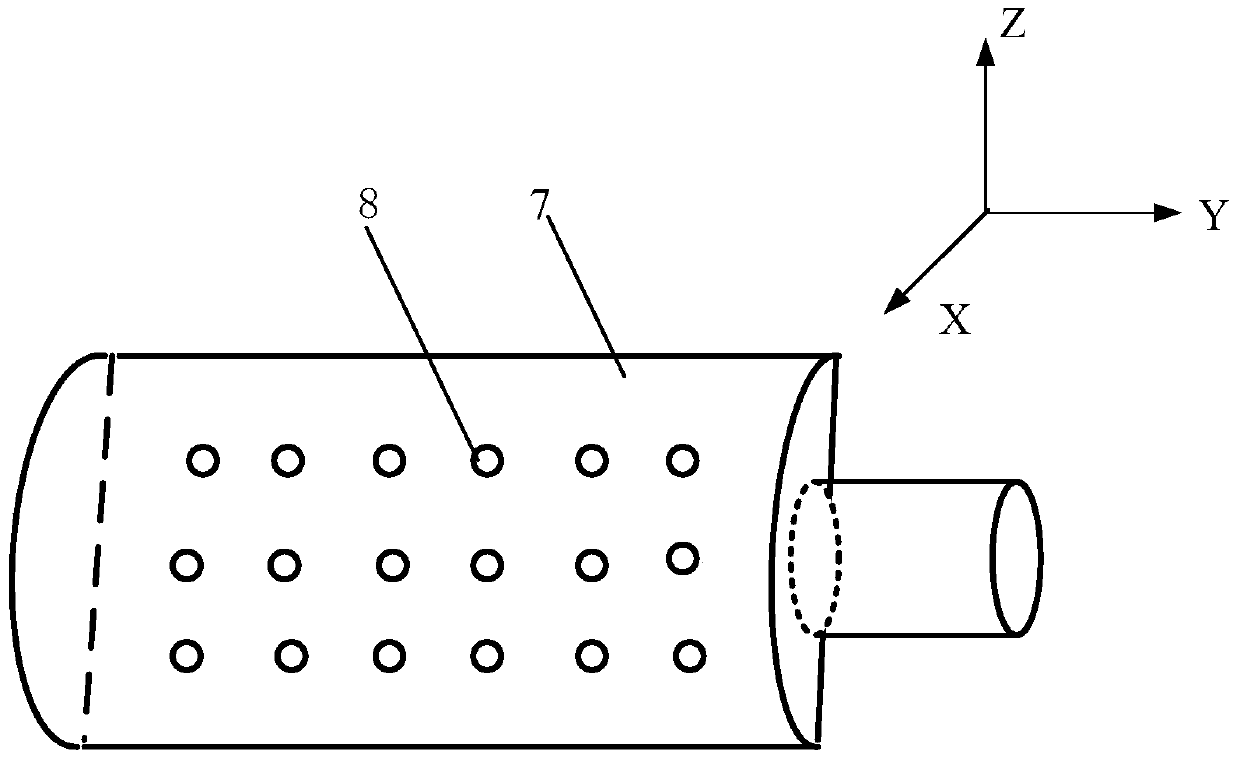

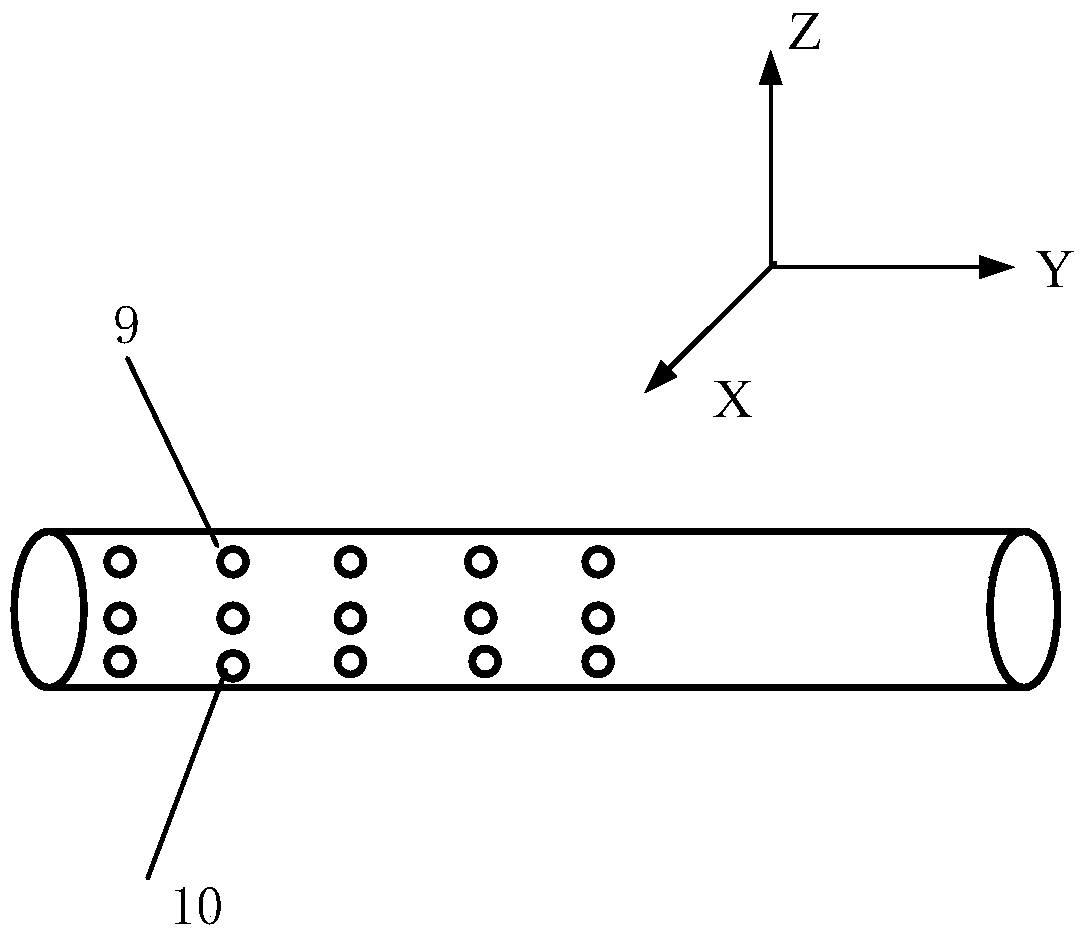

[0020] as attached figure 2 As shown, the cavitator 7 is a closed shell with a vent hole 8 processed on its side, and a connection end is provided on the end surface of one side of the cavitator 7, and the connection end has two interfaces and an internal cavity The left side and the right side of the cavitator 7 are parallel to each other, the upstream surface is perpendicular to the water flow direction, and the vent hole 8 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com