Linkage mechanism and dual-axis solar tracking system having the same

A technology of tracking system and linkage mechanism, which is applied in the field of mechanical equipment, can solve the problems that multiple parallel parts cannot rotate synchronously, difficult linkage, complex control mechanism, etc., and achieve the effect of easy installation and maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

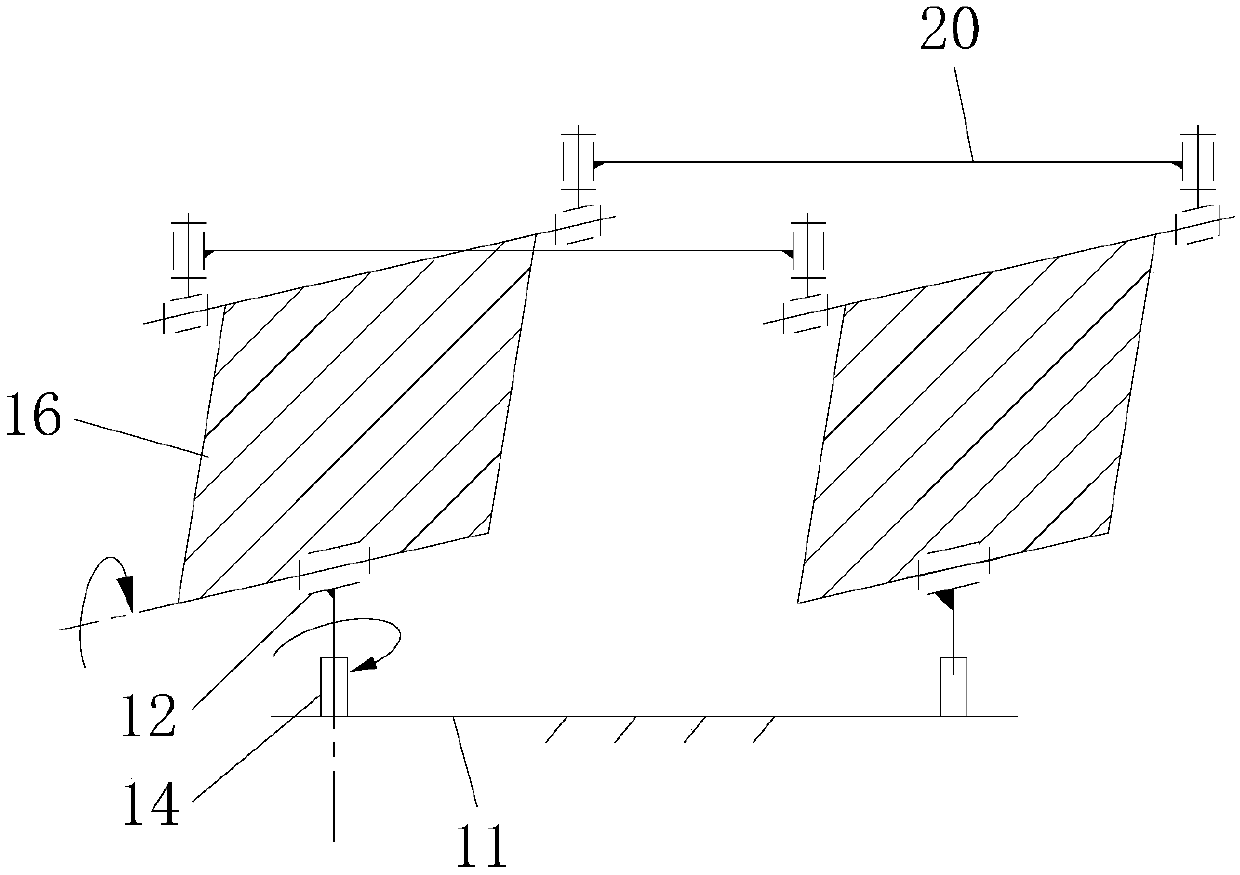

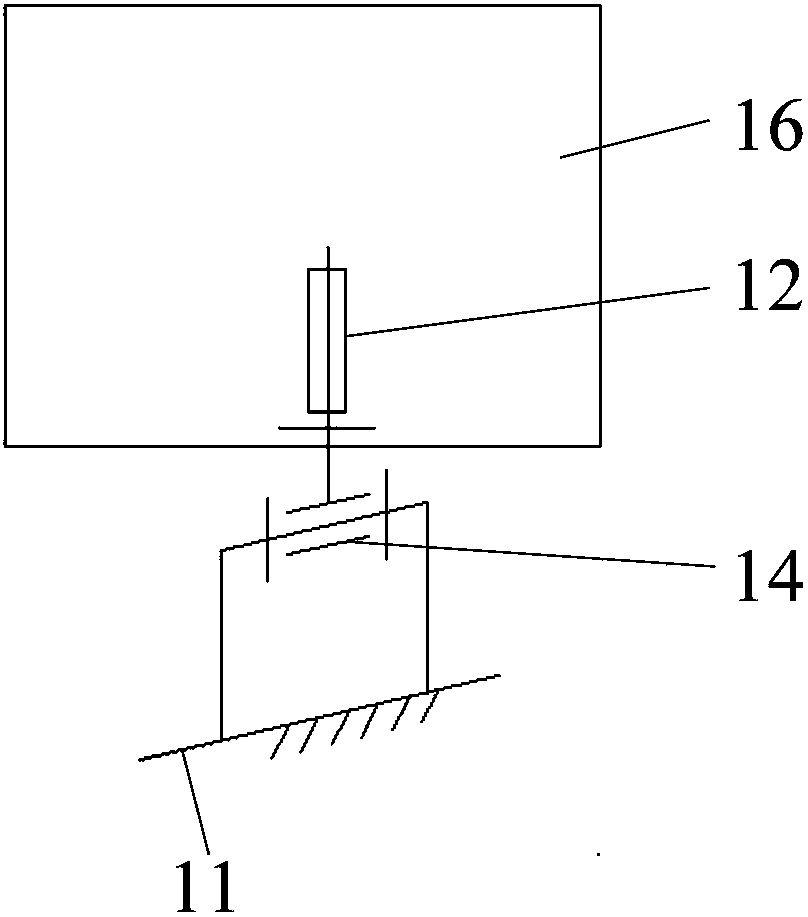

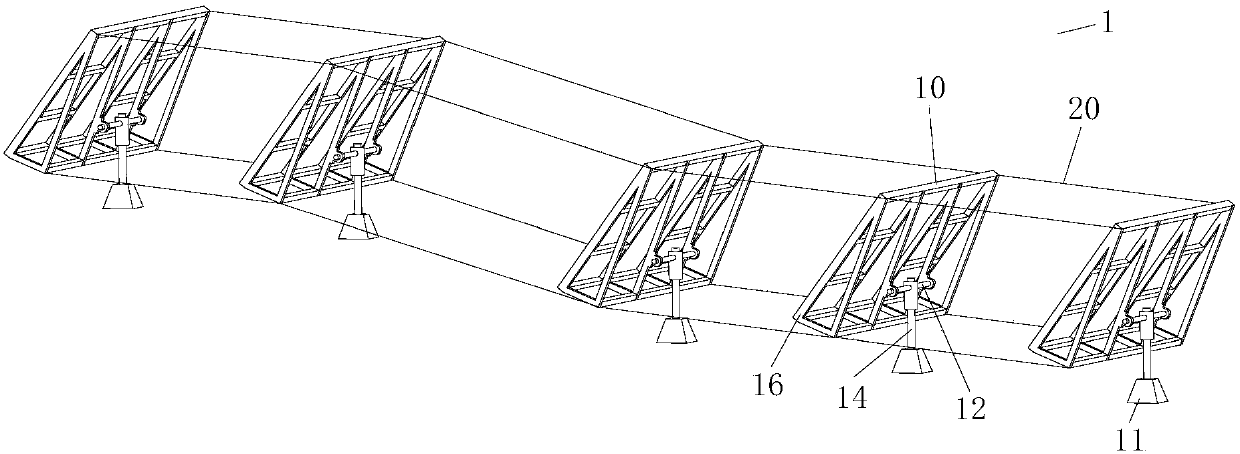

[0030] see figure 1 As shown, the present invention proposes a linkage mechanism 1 , which includes at least two parallel and spaced support assemblies 10 , at least one traction member 20 , and a drive assembly connected to part of the support assemblies 10 . The supporting assembly 10 includes a body 16 , a first rotating shaft 12 , a second rotating shaft 14 perpendicular to the first rotating shaft 12 and a base 11 . The first rotating shaft 12 is used as a rotating pair to connect the body 16 and the second rotating shaft 14 , and the second rotating shaft 14 is used as a rotating pair to connect the first rotating shaft 12 and the base 11 . The puller 20 is connected between adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com