A high-voltage flexible circuit board and multilayer flexible circuit board

A flexible circuit board, high-voltage technology, used in printed circuits, printed circuits, printed circuit components, etc., can solve problems such as shortening the service life and short-circuiting at the welding point of LED lamps, improving production efficiency, reducing overall thickness, and reducing manufacturing. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

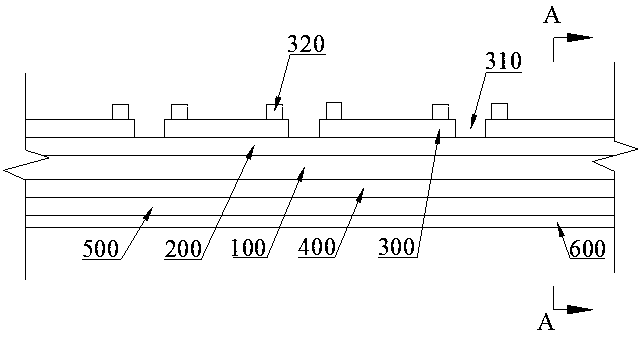

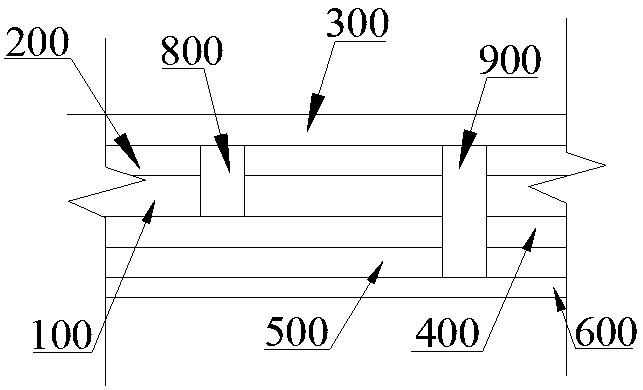

[0027] Such as figure 1 and 2 As shown, a high-voltage flexible circuit board includes an insulating base layer 100, one side of the insulating base layer 100 is provided with a first copper foil circuit layer 200, and the other side is sequentially provided with a second copper foil circuit layer 400, a first PET The film layer 500 and the third copper foil circuit layer 600, the first through hole 800 is provided between the first copper foil circuit layer 200 and the insulating base layer 100 to realize the first copper foil circuit layer 200 and the second copper foil circuit layer 400 conduction, a second through hole 900 is provided between the first copper foil circuit layer 200, the insulating base layer 100, the second copper foil circuit layer 400 and the first PET film layer 500 to realize the first copper foil circuit layer 200 and the third copper foil circuit layer 600.

[0028] The second PET film layer 300 is disposed on the first copper foil circuit layer 20...

Embodiment 2

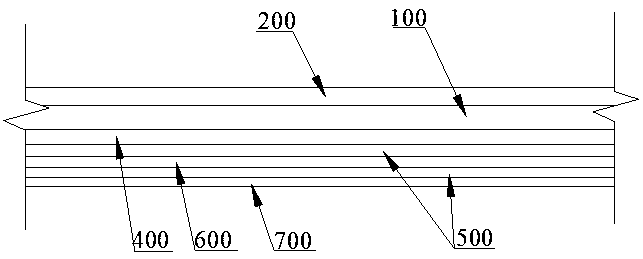

[0030] Such as image 3 As shown, a high-voltage multilayer flexible circuit board includes an insulating base layer 100, one side of the insulating base layer 100 is provided with an upper copper foil circuit layer 200, and the other side is provided with three lower layers of copper foil circuit layers, which are respectively the first The lower copper foil circuit layer 400, the second lower copper foil circuit layer 600 and the third lower copper foil circuit layer 700, and a PET film layer 500 is arranged between the three lower copper foil circuit layers, and the upper copper foil circuit layer The connection between 200 and the lower copper foil circuit layer is realized through the through hole penetrating through the insulating base layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com