A kind of preparation method of nanocrystalline cellulose magnetic particle

A nanocrystalline cellulose, magnetic particle technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of low adsorption capacity, affecting adsorption selectivity and adsorption capacity, and not suitable for range and other issues, to achieve the effect of large adsorption capacity, low cost and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

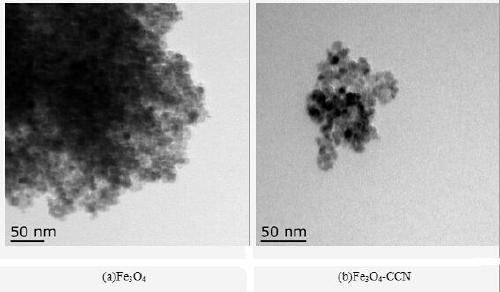

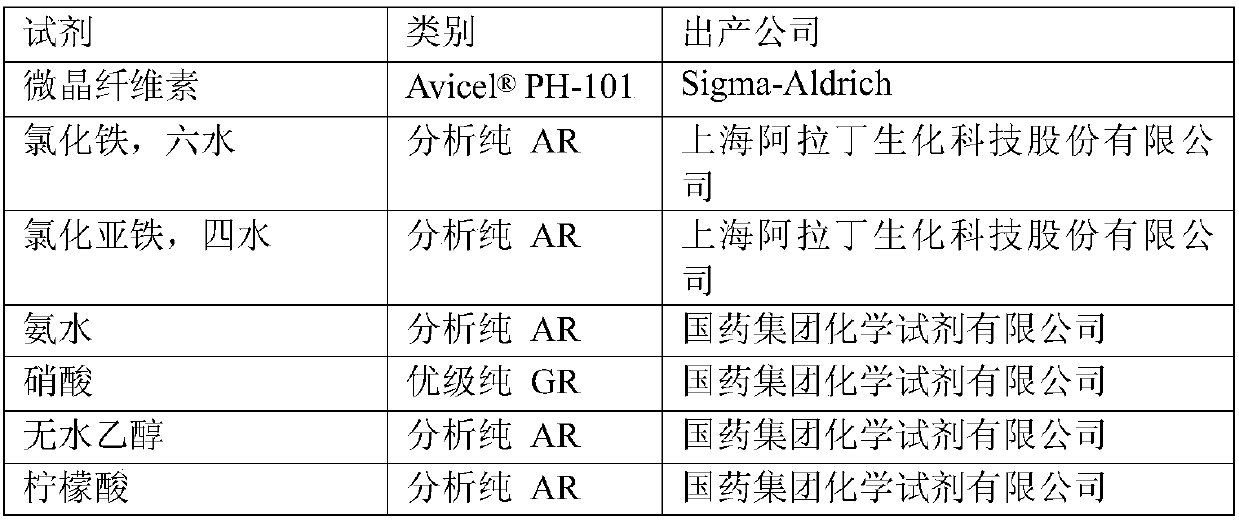

[0025] A method for preparing nanocrystalline cellulose magnetic particles, the preparation method is to prepare nanocrystalline cellulose from microcrystalline cellulose, then prepare semi-finished products of nanocrystalline cellulose magnetic particles through graft modification, and finally prepare nanocrystalline cellulose magnetic particles Wrapped in microcapsules to obtain nanocrystalline cellulose magnetic particles.

[0026] The preparation method of microcrystalline cellulose to prepare nanocrystalline cellulose is: 6gMCC plus 200mL of 2mol / L ammonium persulfate solution, mix well, soak for a period of time, place in an ultrasonic 70KHz reactor, stir and react at 60°C, after the reaction To obtain a suspension, place the suspension in a high-speed centrifuge at 9000r / min for repeated centrifugation and washing to near neutrality, dissolve the prepared colloidal substance with 200mL1mol / L citric acid solution, and continue to stir and react in an ultrasonic reactor at...

Embodiment 2

[0031]A method for preparing nanocrystalline cellulose magnetic particles, the preparation method is to prepare nanocrystalline cellulose from microcrystalline cellulose, then prepare semi-finished products of nanocrystalline cellulose magnetic particles through graft modification, and finally prepare nanocrystalline cellulose magnetic particles Wrapped in microcapsules to obtain nanocrystalline cellulose magnetic particles.

[0032] The preparation method of microcrystalline cellulose to prepare nanocrystalline cellulose is: 6gMCC plus 200mL of 2mol / L ammonium persulfate solution, mix well, soak for a period of time, place in an ultrasonic 80KHz reactor, stir and react at 60°C, after the reaction To obtain a suspension, place the suspension in a high-speed centrifuge at 9000r / min for repeated centrifugation and washing to near neutrality, dissolve the prepared colloidal substance with 200mL1mol / L citric acid solution, and continue to stir and react in an ultrasonic reactor at ...

Embodiment 3

[0037] A method for preparing nanocrystalline cellulose magnetic particles, the preparation method is to prepare nanocrystalline cellulose from microcrystalline cellulose, then prepare semi-finished products of nanocrystalline cellulose magnetic particles through graft modification, and finally prepare nanocrystalline cellulose magnetic particles Wrapped in microcapsules to obtain nanocrystalline cellulose magnetic particles.

[0038] The preparation method of microcrystalline cellulose to prepare nanocrystalline cellulose is: 6gMCC plus 200mL of 2mol / L ammonium persulfate solution, mix well, soak for a period of time, place in an ultrasonic 90KHz reactor, stir and react at 60°C, after the reaction To obtain a suspension, place the suspension in a high-speed centrifuge at 9000r / min for repeated centrifugation and washing to near neutrality, dissolve the prepared colloidal substance with 200mL1mol / L citric acid solution, and continue to stir and react in an ultrasonic reactor at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com