A screening type reloading crusher

A crusher and loader technology, which is applied in conveyors, grain processing, transportation and packaging, etc., can solve the problems of large installation equipment transportation and crushing space, large dust and noise, and many structural equipment, and achieves compact and novel structure. The effect of reducing space and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

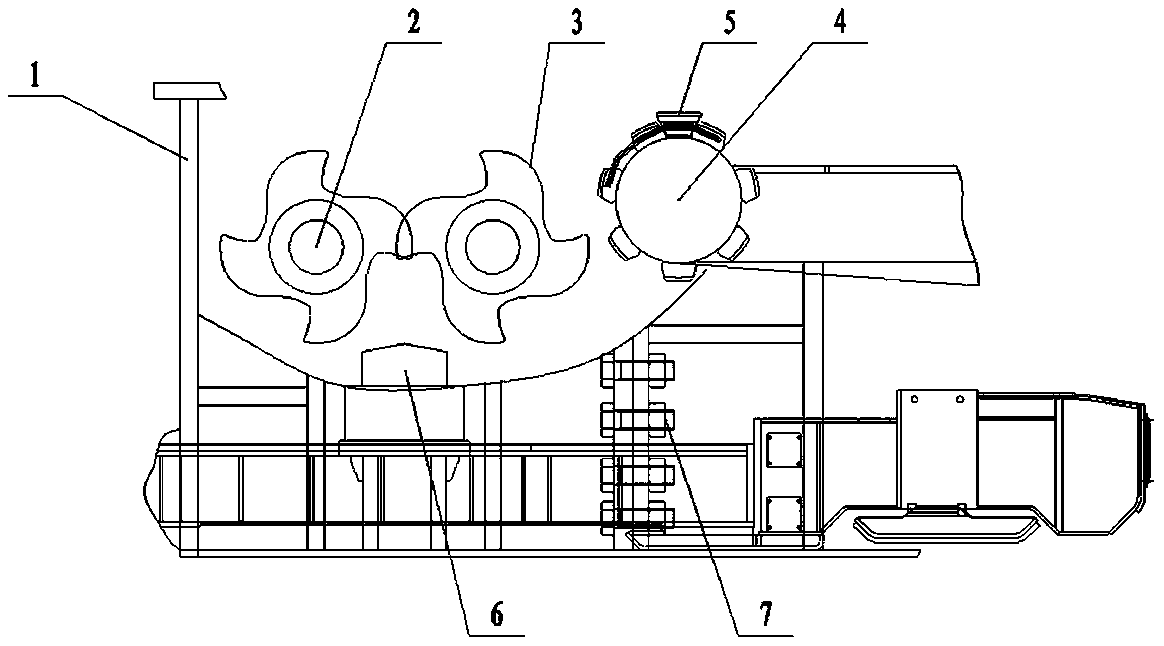

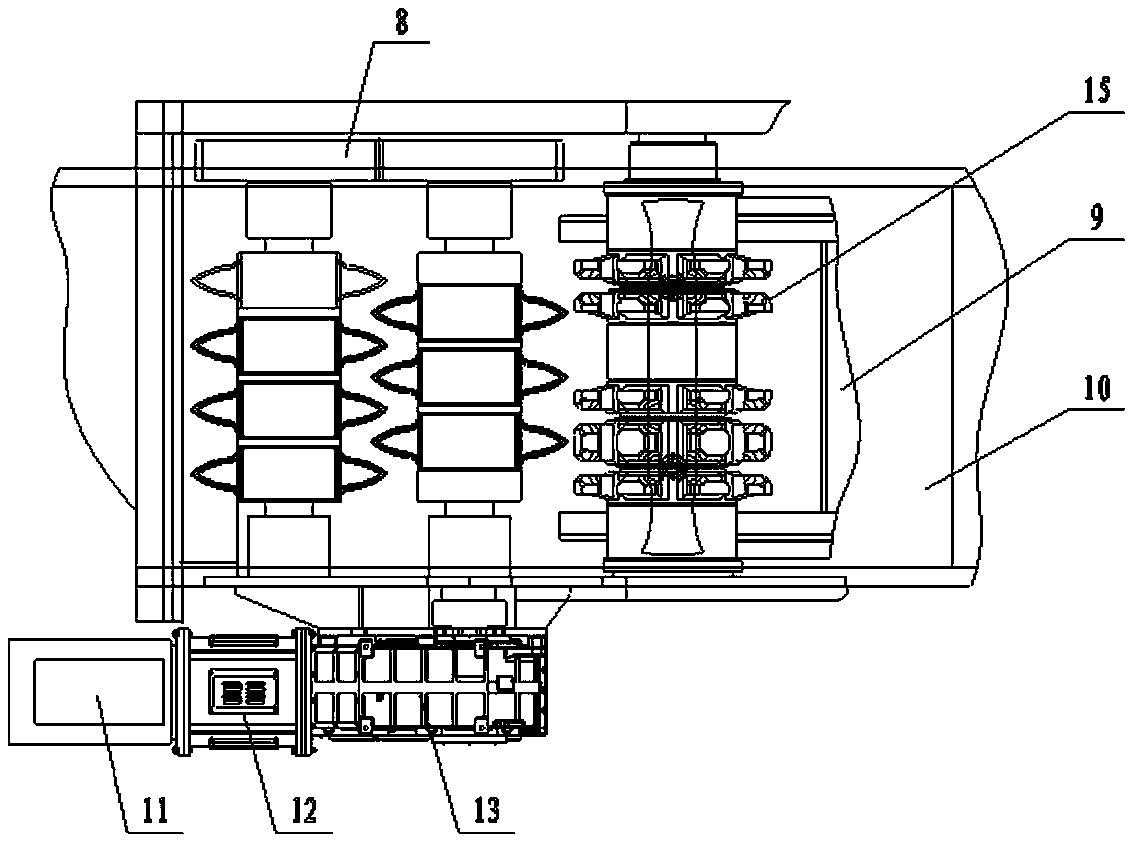

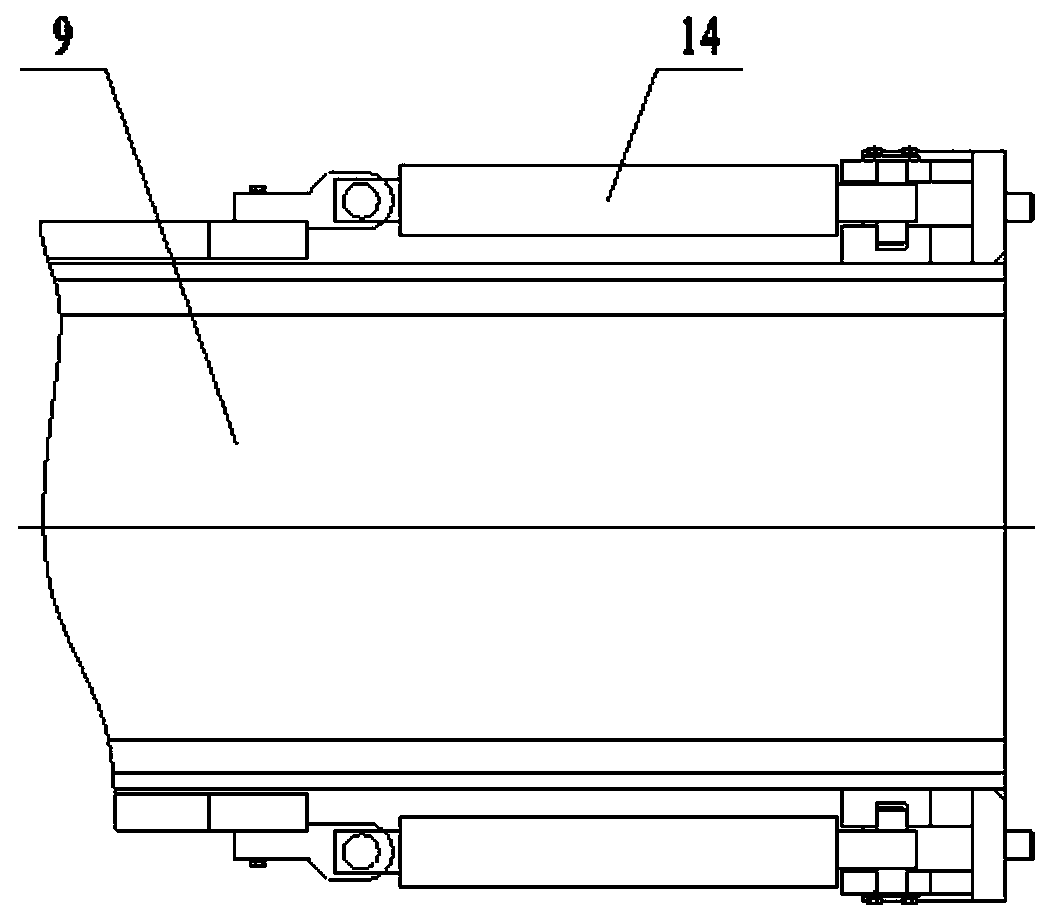

[0024] The following embodiments will further describe the present invention in conjunction with the drawings.

[0025] Such as Figure 1-Figure 3 As shown, the detachable frame 1 is connected to the head of the transfer machine through a screw and nut structure 7 for easy disassembly. Two toothed rollers 2 and a transfer machine head sprocket assembly 4 are installed on the detachable frame 1. The sprocket assembly 4 is connected to a telescopic groove 9 which is adjusted by the hydraulic control structure 14 to move left and right; There is no traditional tongue plate structure between the wheel assembly 4 and the telescopic groove 9, which can preliminarily screen coal and ore of suitable particle size to avoid over-crushing; the toothed roller 2 adopts a spiral structure, and one of the toothed rollers 2 is the main One end of the drive shaft is connected to the reducer 13, the coupler 12 and the motor 11, and the other end is connected to the other toothed roller 2 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com