Preparation system and method of rock-fill dam bedding material

A technology for preparing a system and a cushion material, which is applied in the field of reducing consumption and completing a cushion material preparation system for a rockfill dam with high quality, can solve the problems of high cost, discontinuous gradation, and difficulty in meeting the permeability coefficient of cushion material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

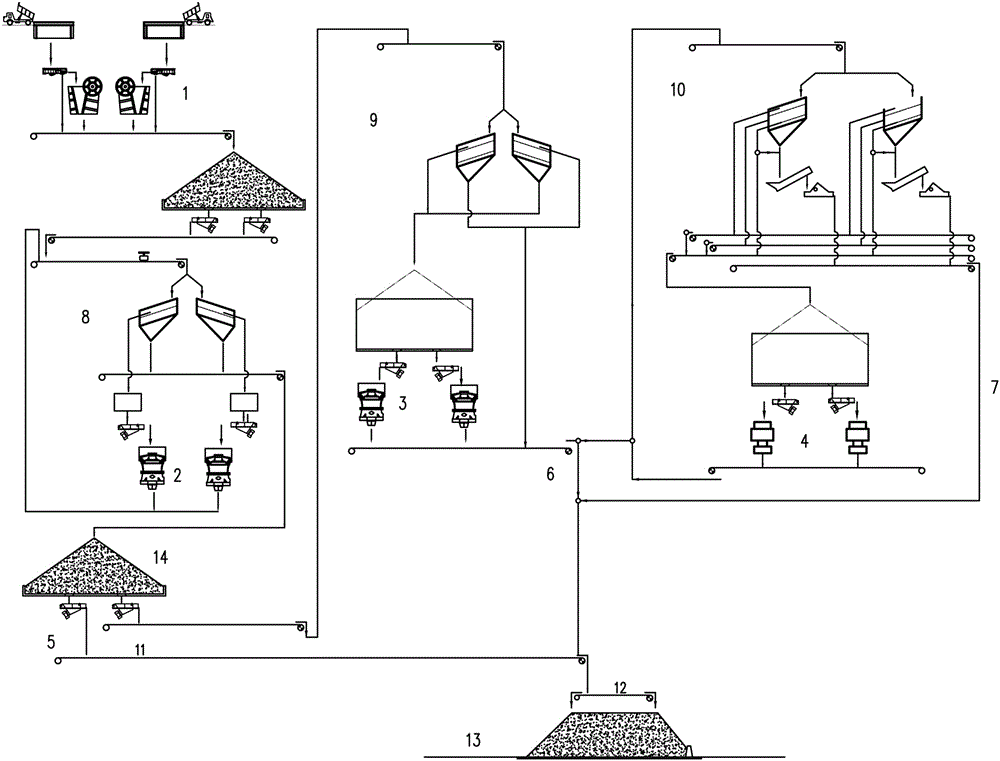

[0021] A preparation system for cushion material of a face rockfill dam, the system includes a coarse crushing section 1, a first screening section 8 is provided under the coarse crushing section 1, a secondary crushing section 2 is provided below the first screening section 8, and a secondary crushing section 2 is provided below the primary screening section 8. The second screening section 9 is provided under the section 2, the fine crushing section 3 is arranged under the second screening section 9, the main screening section 10 is arranged under the fine crushing section 3, and the ultrafine crushing section 4 is arranged under the main screening section 10; After the crushing section 2, there is a first-stage cushion finished material retrieving point 5, after the fine crushing section 3, a second-stage cushion product retrieving point 6, and after the ultra-fine crushing section 4, a third-stage cushion product The material retrieving point 7, the cushion finished material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com