Handheld force feedback device and method for realizing force sense reproduction using the device

A force feedback, handheld technology, applied in the direction of manipulators, program control manipulators, manufacturing tools, etc., can solve the problems of poor practicability and achieve the effect of strong practicability and avoiding fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

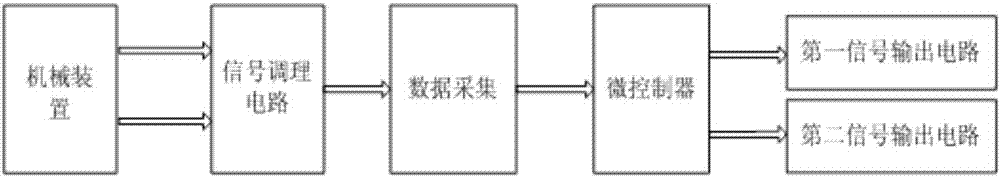

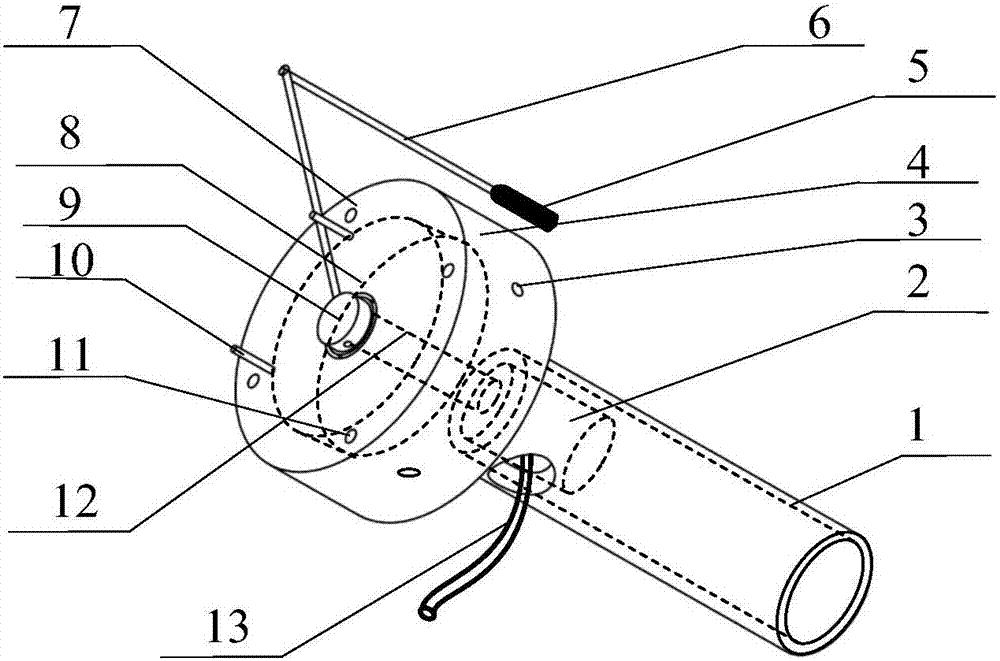

[0018] refer to Figure 1-2 . In the mechanical device of the hand-held force feedback device, the torque motor drives the rocker for finger grasping, and the rocker is equipped with a force sensor to measure the grasping force of the finger. The torque motor is coaxially fixed with an encoder for measuring angular displacement. The force feedback device provides the two signals of the angular displacement measured by the encoder and the force signal of the rocker to the microcontroller for data collection through signal conditioning and data conversion interfaces. The microcontroller converts the angular displacement signal into a certain format and outputs it to the remote end through the first signal output circuit for the remote end to obtain information from the manipulator. The second signal output of the microcontroller realizes the given control signal to the torque motor.

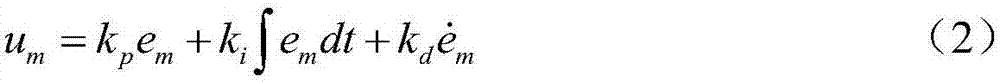

[0019] In the mechanical device of the force feedback device, the reproduction of the local ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com