System and method for adjusting the land channel length of an extrusion die

A technology of extrusion die and flat part, which is applied in the system field of channel length of the flat part, can solve problems such as product orientation and shrinkage, damage to processing characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following detailed description is exemplary in nature and is not intended to limit the scope, applicability, or configuration of the invention in any way. The description provides practical illustrations for implementing certain preferred embodiments of the invention. Examples of configurations, materials, dimensions, and manufacturing processes are provided for selected elements; all other elements use what is known to one of ordinary skill in the field of the invention. Those of ordinary skill in the art will recognize that there are many suitable substitutions for many given examples.

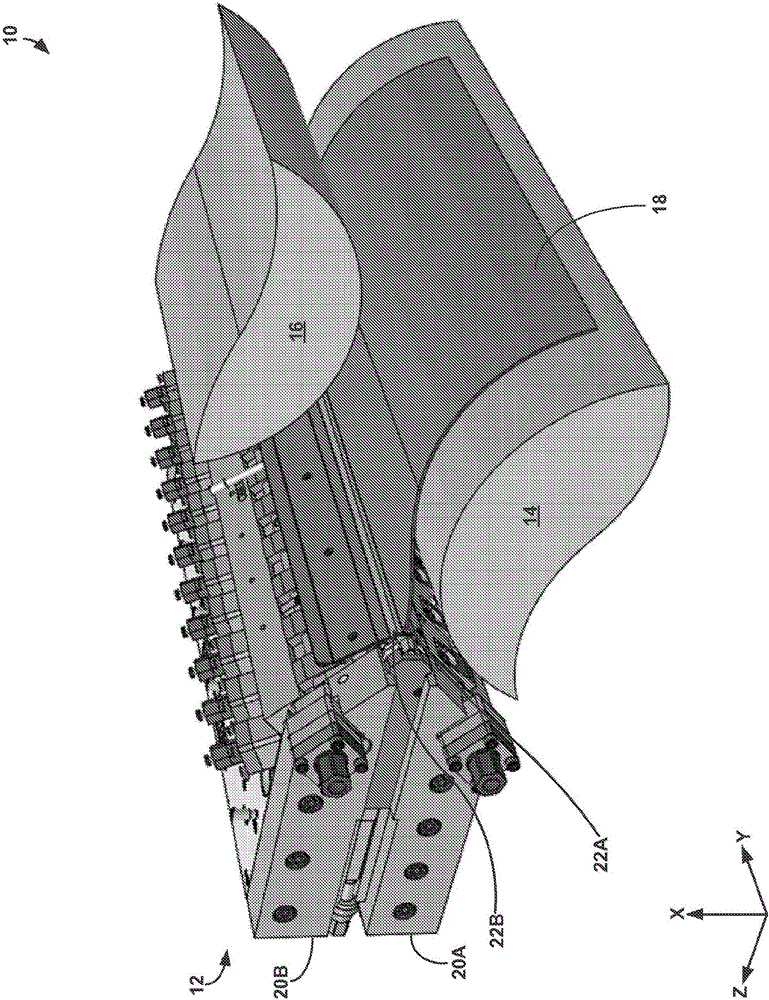

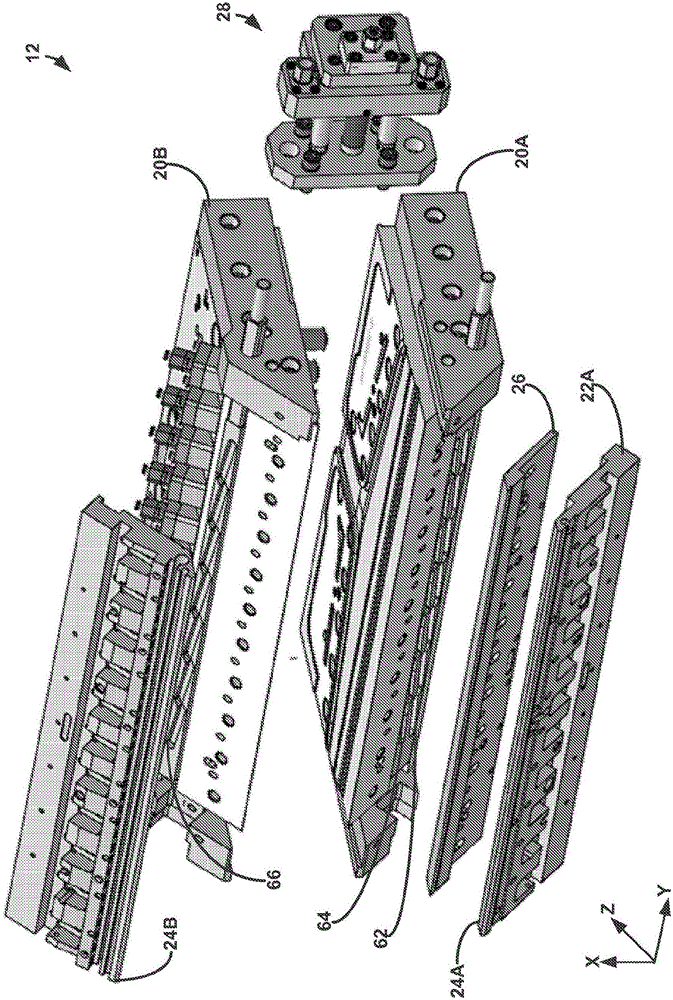

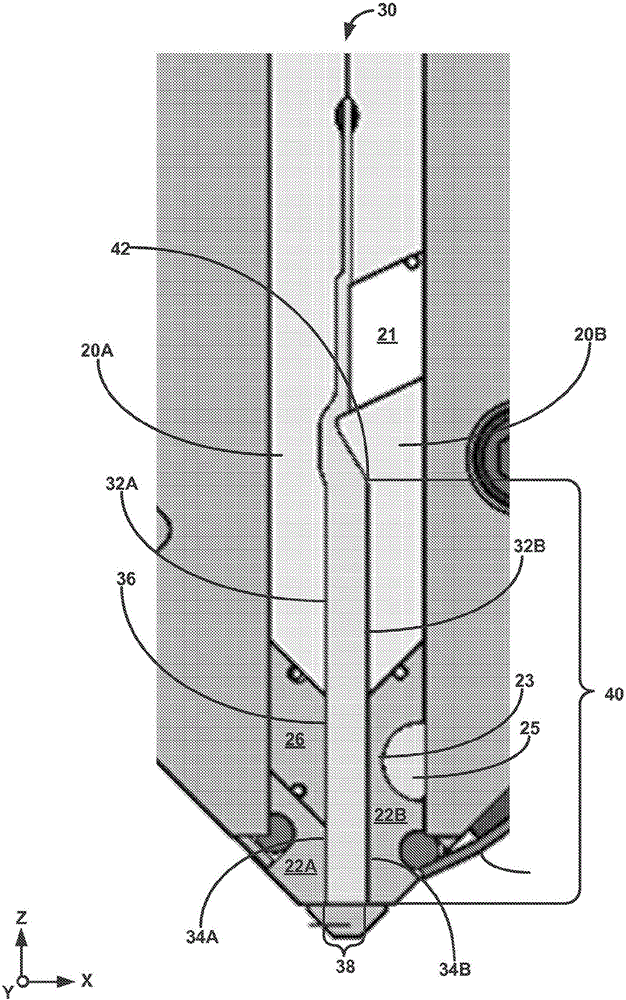

[0019] The present disclosure relates to an extrusion die having a flat channel and a method for adjusting the length of the flat channel. In one embodiment, the extrusion die has a pair of die body portions providing polymer flow channels therethrough. The die body portion has a corresponding pair of die lips that form an outlet hole to a polymer flow channel. The terminal por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com