Movable type cleaning system of oil pressing mechanism

A cleaning system and movable technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of affecting the oil output efficiency of the pressing mechanism, difficult cleaning of the pressing rod and the pressing chamber, and troublesome operation of the pressing mechanism, so as to achieve easy processing and easy falling off , easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

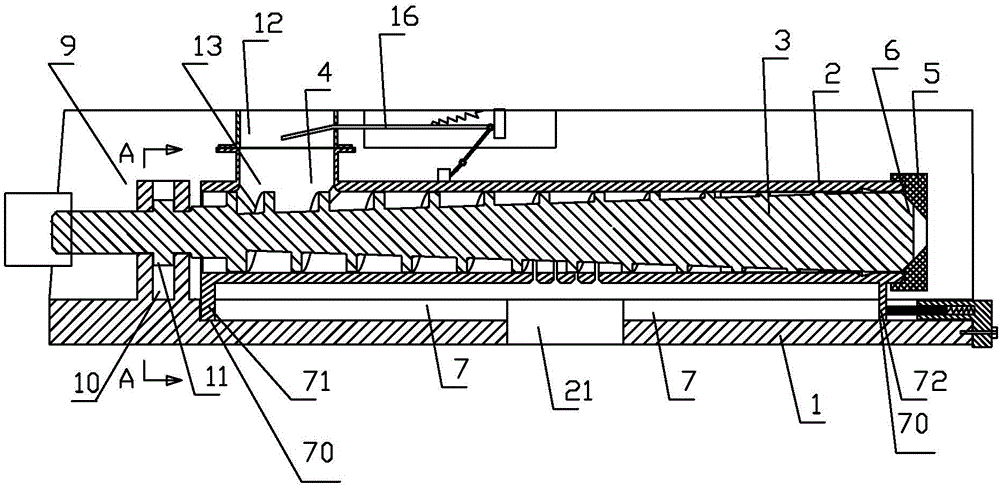

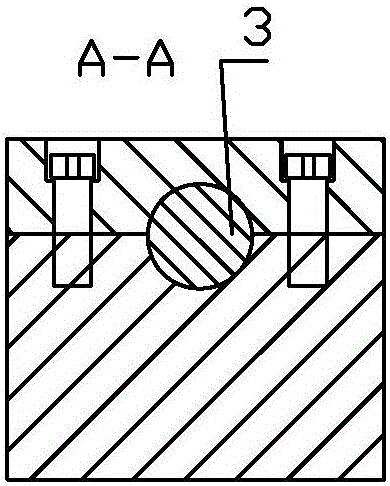

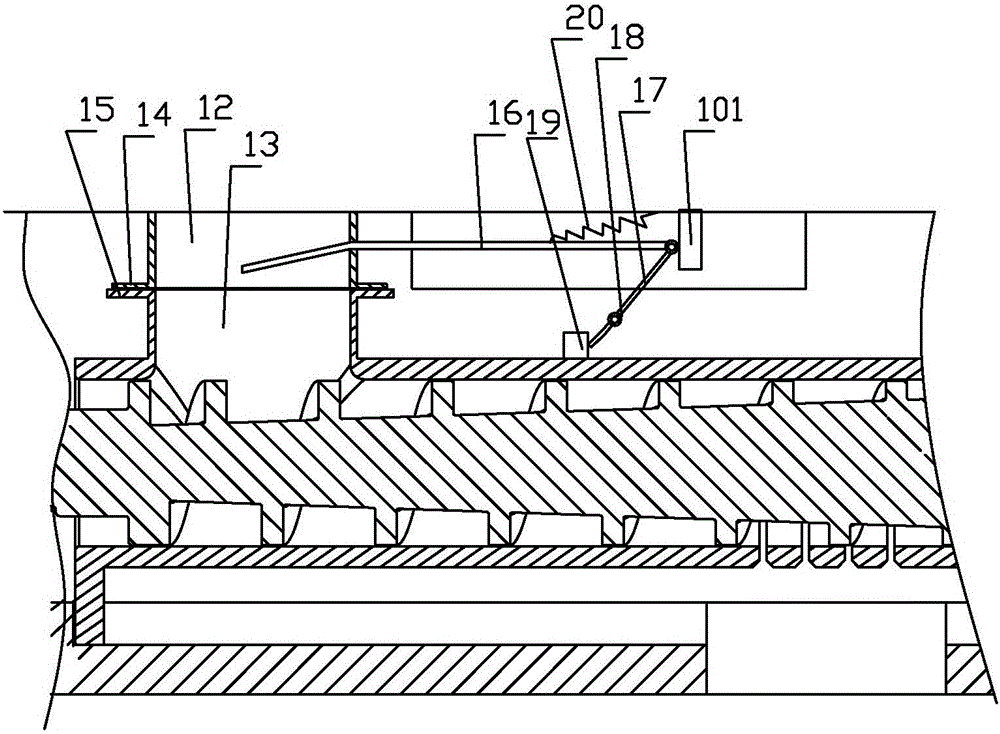

[0045] Embodiment 1: as Figure 1 to Figure 11 As shown, a movable oil press mechanism cleaning system includes a component seat 1, a press chamber 2, and a press rod 3, and the press rod 3 is located in the press chamber; the press chamber 2 includes a conveying material section and a pressing section; the conveying material section is provided with The feeding hole 4, the conveying section and the pressing section are arranged in sequence, the conveying section and the pressing section are integrally formed, and the conveying section and the pressing section are on the same axis; the end of the pressing section is detachably connected with a tail sleeve 5; The tail end of the platform is provided with a platform body section 6, the outer diameter of the platform body section 6 gradually becomes smaller in the axially outward direction, and the inner wall of the tail sleeve 5 matches the outer wall 60 of the platform body section 6. The movable oil pressing mechanism includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com