Automatic film tearing mechanism

An automatic and mechanism-adjusting technology, which is applied in packaging, transportation and packaging, and unsealing of objects, can solve problems such as high cost, easily damaged electronic products, and complex structure, and achieve low cost, environmentally friendly and clean cost, and compact mechanism structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

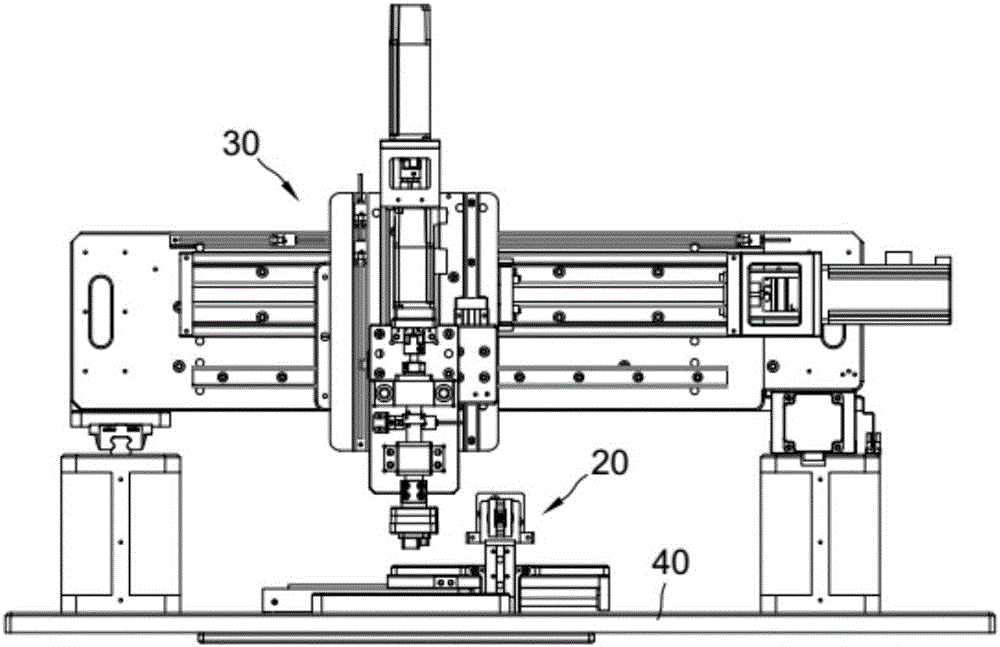

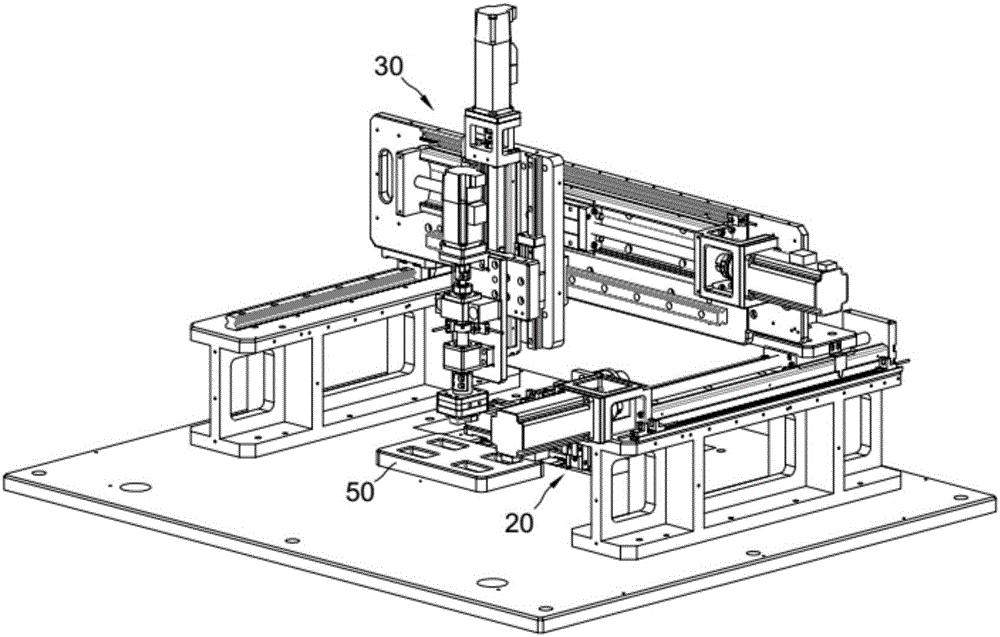

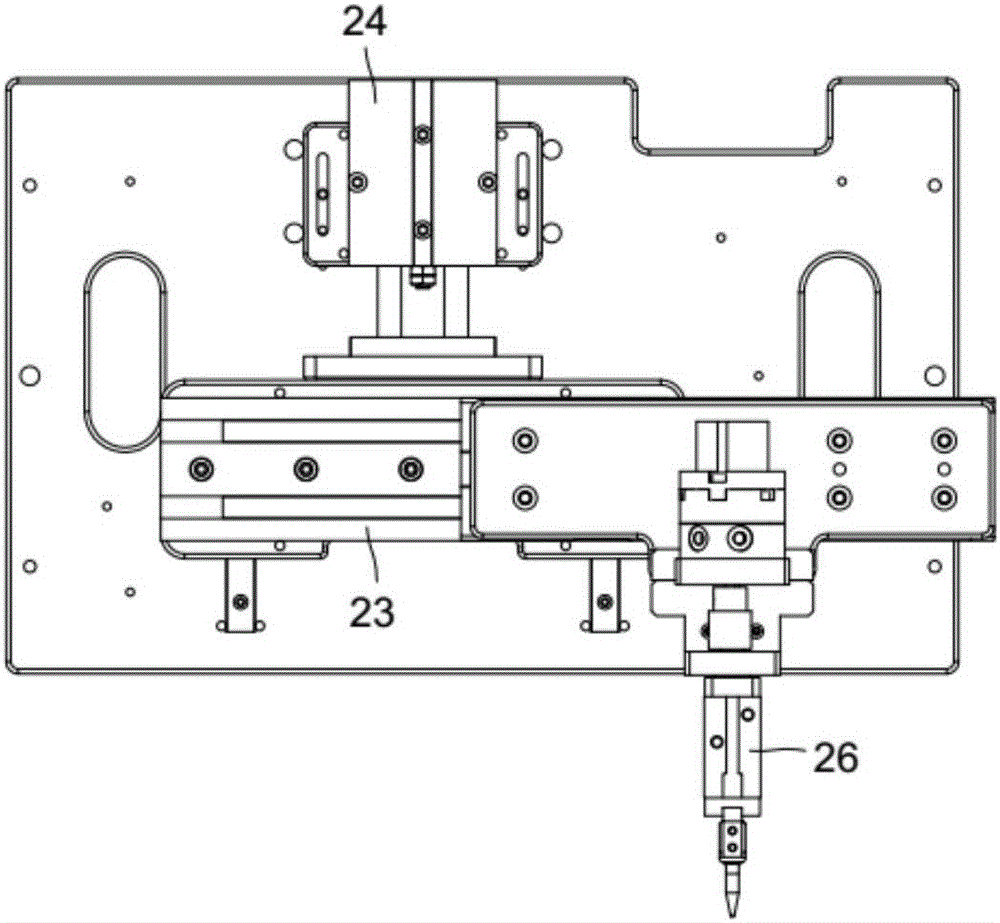

[0035] combine figure 1 , figure 2 , an automatic film tearing mechanism, including an adsorption pressure head 10 for absorbing products, and a film tearing mechanism 20 for tearing off the film material from the product; On the bit moving mechanism 30.

[0036] combine Figure 6 to Figure 8 , the alignment movement mechanism 30 includes an X-axis adjustment mechanism 31 , a Y-axis adjustment mechanism 32 , a Z-axis adjustment mechanism 33 , and an R-axis adjustment mechanism 34 .

[0037] Regarding the above-mentioned alignment movement mechanism 30, the Y-axis adjustment mechanism includes a pair of parallel Y-axis slide rails 321, a Y-axis slide block 322 matched on the Y-axis slide rails, and drives the Y-axis slide block to move along the Y-axis slide rails. The Y-axis drive mechanism. The Y-axis slide rail 321 is installed on the Y-axis support plate 326, and the Y-axis support plate 326 is installed on the mechanism bottom plate; the Y-axis slider is fixed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com