Blanking carrying suction cup frame drive mechanism

A technology of driving mechanism and suction cup frame, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low efficiency, high labor intensity of unloading and handling, and achieve a clear working principle, reduce handling intensity, and mechanism structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

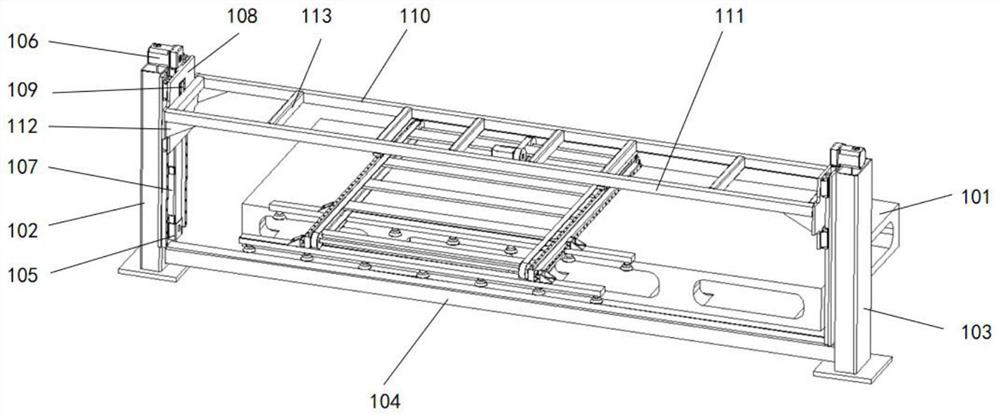

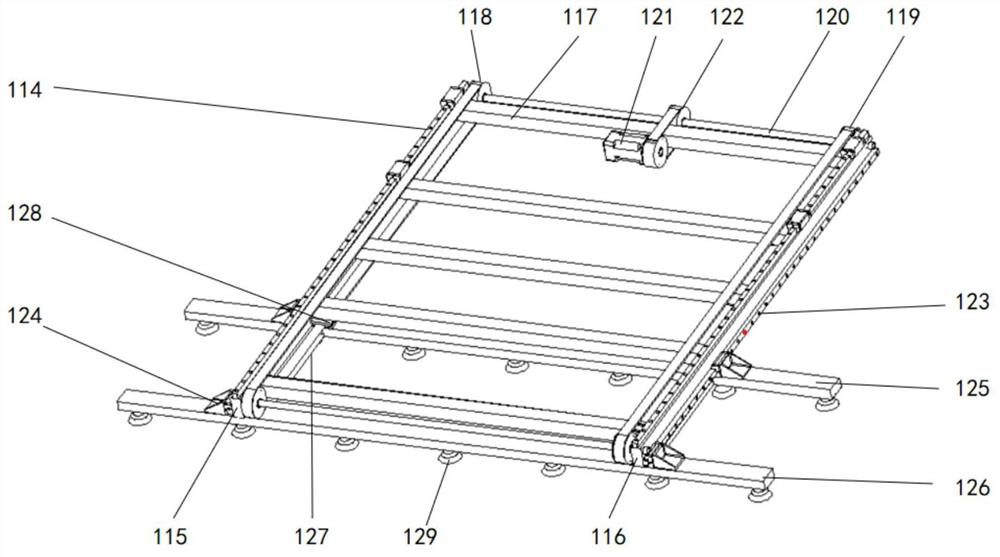

[0014] Such as Figure 1-2 As shown, a driving mechanism for a blanking and handling suction cup frame is composed of a material stacking platform 101, a first support 102, a second support 103, a beam 104, a mobile module 105, a mobile module drive motor 106, a connecting plate guide rail 107, and a connecting plate 108 , connecting plate slide block 109, connecting frame first bracket 110, connecting frame second bracket 111, stiffener plate 112, connecting frame crossbeam 113, mechanical arm carrying frame guide rail 114, mechanical arm carrying frame first support 115, mechanical arm carrying Frame second support 116, mechanical arm carrying frame crossbeam 117, mechanical arm first belt conveying mechanism 118, mechanical arm second belt conveying mechanism 119, mechanical arm connecting rod 120, mechanical arm belt conveying mechanism driving motor 121, mechanical arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com