A method for preparing nanorod crystal hydroxyapatite hydrosol

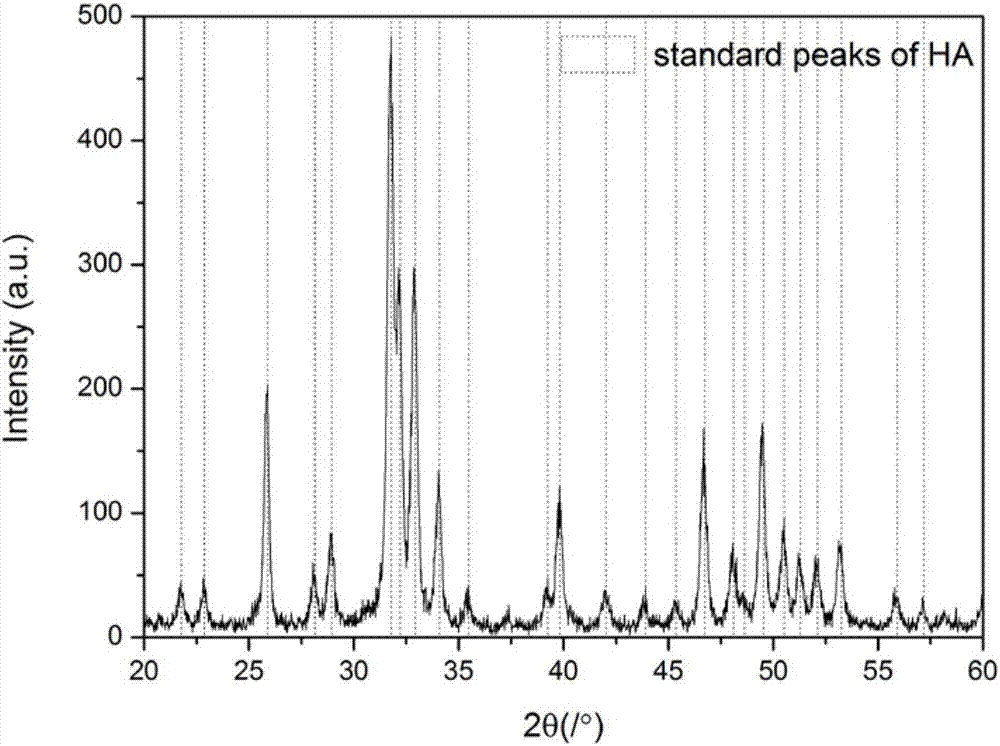

A technology of crystalline hydroxyapatite and hydroxyapatite, which is applied in the field of synthesis of nano-biological ceramics, can solve the problems of strict reaction conditions, etc., and achieve the effect of rich sources, fine grains, and increased nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) prepare the mixed solution of calcium nitrate and calcium chloride of 0.1M, add citric acid, form mixed solution A; Prepare the mixed solution B of 0.1M potassium phosphate and ammonium phosphate; Calcium ion in two kinds of solutions: phosphate ion: lemon The molar ratio of acid radical ion is 1:0.67:1;

[0025] 2) Slowly add the above-mentioned mixed solution A into the solution B at a rate of 0.5ml / min, and stir while dropping to form a mixed solution C. After the addition, add ammonia water to adjust the pH of the solution to 9, and fully react Afterwards, the mixed solution C was aged at room temperature for 24h;

[0026] 3) The above-mentioned aged mixed solution C was stirred again at high speed for 1.5 h, aged for 24 h, and repeated 2 times;

[0027] 4) Use a high-speed centrifuge to centrifuge the above solution to obtain a precipitate, use deionized water and absolute ethanol to alternately centrifuge and wash the precipitate 4 times to remove excess elect...

Embodiment 2

[0030] 1) Prepare 0.5M calcium nitrate solution, add citric acid to form mixed solution A; prepare 0.5M ammonium phosphate solution B; in the two solutions, calcium ion: phosphate ion: the molar ratio of citrate ion is 1:0.67:0.7 ;

[0031] 2) Slowly add the above-mentioned mixed solution A into the solution B at a rate of 1ml / min, and stir while dropping to form a mixed solution C. After the addition is completed, add ammonia water to adjust the pH value of the solution to 11, and fully react Afterwards, the mixed solution C was aged at room temperature for 24h;

[0032] 3) The above-mentioned aged mixed solution C was stirred again at high speed for 2 hours, aged for 24 hours, and repeated twice;

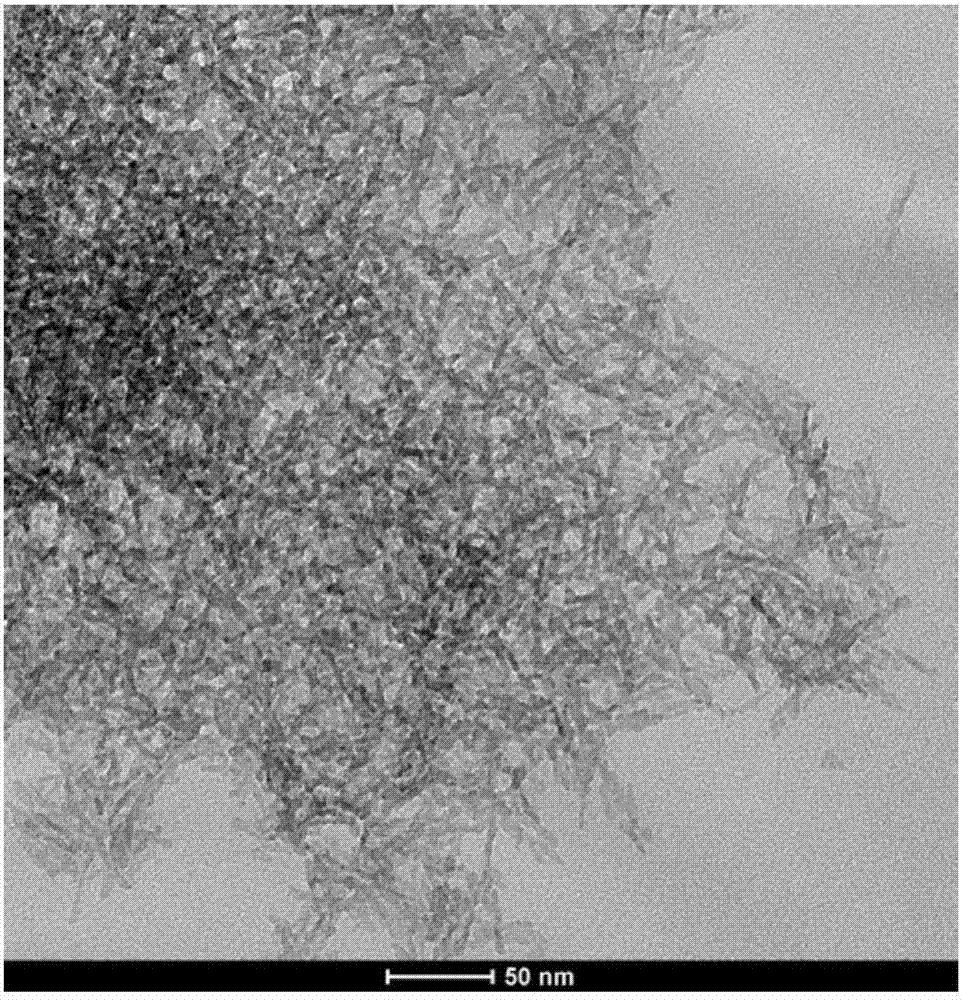

[0033] 4) Use a high-speed centrifuge to centrifuge the above solution to obtain a precipitate, use deionized water and absolute ethanol to alternately centrifuge and wash the precipitate twice to remove excess electrolyte in the system, and obtain a crystal with a diameter of 5-...

Embodiment 3

[0036] 1) prepare the mixed solution of 0.3M calcium nitrate and calcium acetate, add citric acid, form mixed solution A; prepare the mixed solution B of 0.3M ammonium phosphate and potassium phosphate; calcium ion in two kinds of solutions: phosphate ion: citrate ion The molar ratio is 1:0.67:1.2;

[0037] 2) Slowly add the above-mentioned mixed solution A into the solution B at a rate of 0.8ml / min, and stir while dropping to form a mixed solution C. After the addition, add ammonia water to adjust the pH value of the solution to 10, and fully react Afterwards, the mixed solution C was aged at room temperature for 24h;

[0038] 3) The above-mentioned aged mixed solution C was stirred again at high speed for 1 h, aged for 24 h, and repeated 2 times;

[0039] 4) Use a high-speed centrifuge to centrifuge the above solution to obtain a precipitate, and use deionized water and absolute ethanol to alternately centrifuge and wash the precipitate 3 times to remove excess electrolyte ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com