Device and process for producing high-purity parachlorophenol

A p-chlorophenol and production device technology, applied in the chemical industry, can solve the problems of inability to extract high-purity p-chlorophenol and environmental pollution, and achieve the effects of reducing equipment maintenance costs, reducing production costs, and simple production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

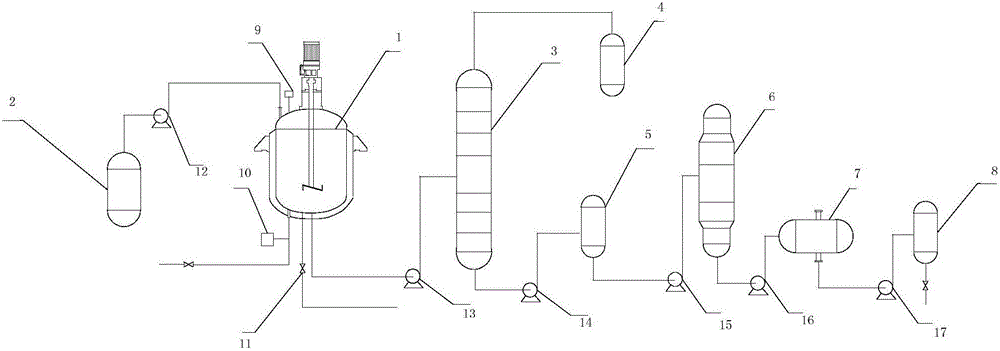

[0025] Present embodiment provides a kind of production device of high-purity p-chlorophenol, structure such as figure 1 As shown, it includes reactor 1, storage tank 2, distillation tower 3, receiving tank 4, condensation tank 5, decompression tower 6, separator 7, product tank 8; the top of the reactor is provided with feed inlet and temperature Measuring port 9, a discharge port, a chlorine gas pipeline and an exhaust valve are provided at the bottom of the reaction kettle, a gas flow meter 10 is arranged on the chlorine gas pipeline, and a connecting pipeline and a first centrifugal pump 12 are arranged between the reaction kettle 1 and the storage tank 2 , a connecting pipeline and a second centrifugal pump 13 are provided between the discharge port at the bottom of the reactor 1 and the distillation tower 3, a connecting pipeline is provided between the receiving tank 4 and the top of the distillation tower 3, and the condensation tank 5 and the distillation tower 4 A co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap