Self-balancing reverse locking wheel structure of suspension basket

It is a self-balancing technology with reverse buckle, which is applied in the erection/assembly of bridges, bridges, buildings, etc. It can solve the problems of derailment, overturning, and poor self-balancing ability of hanging baskets, and achieves improved construction efficiency, simple structural design, and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

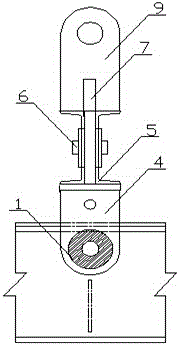

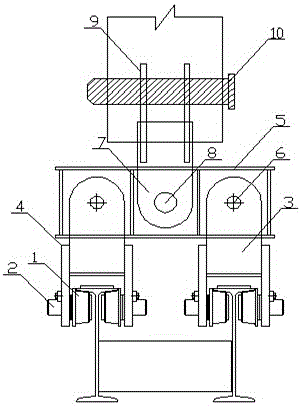

[0013] Embodiments of the present invention: it includes reverse buckle wheel 1, reverse buckle wheel connecting plate 4, reverse buckle wheel pin shaft 2, reverse buckle wheel suspension plate 3, distribution beam 5, reverse buckle wheel suspension plate pin shaft 6, distribution beam suspension Plate 7, distribution beam hanging plate pin shaft 8, hanging basket rear anchor hanging plate 9, hanging basket rear anchor pin shaft 10; reverse buckle wheel 1 and reverse buckle wheel connecting plate 4 are connected through reverse buckle wheel pin shaft 2, and reverse buckle wheel The hanging plate 3 is welded between two connecting plates 4 of the buckle wheel, the hanging plate 3 of the buckle wheel is connected to the distribution beam 5 through the pin shaft 6 of the hanging plate of the buckle wheel, and the hanging plate 7 of the distribution beam is connected to the distribution beam through the hanging plate of the distribution beam Bearing pin 8 is pinned, distribution be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com