A kind of enamel steel plate and its construction structure and construction method

A steel plate and enamel technology, which is applied in the field of enamelled steel plate and its construction structure and construction method, can solve the problems of flatness and verticality error, straight line and plane error, and affect the effect of perception, so as to reduce the error requirement, ensure the construction effect, The effect of reducing the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 An enamelled steel plate

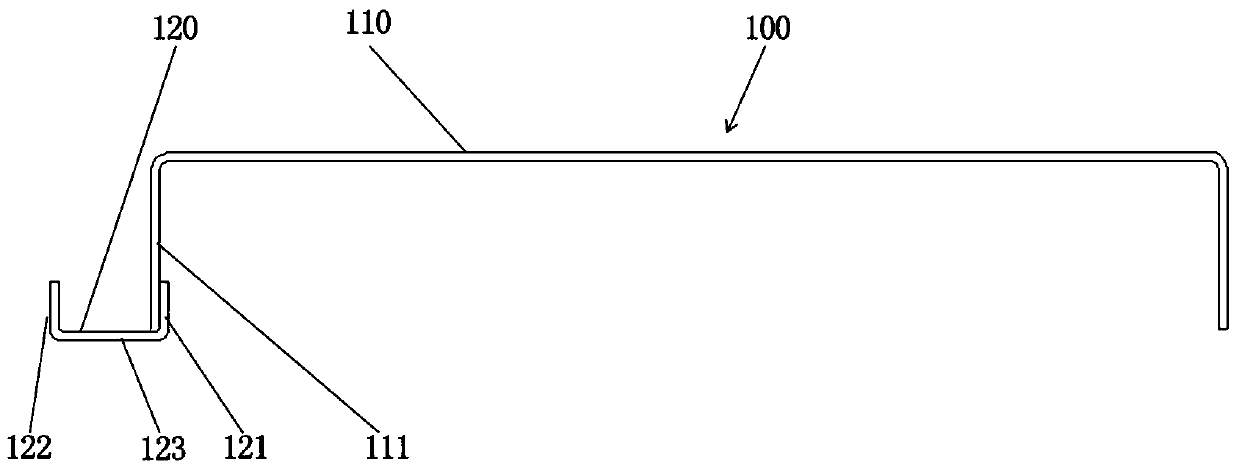

[0025] Such as figure 1 As shown, the present embodiment provides an enamelled steel plate 100 , which includes an enameled steel plate body 110 and a connecting bar 120 .

[0026] The edge of the enamelled steel plate body 110 is folded toward one side to form a wrapping 111 . In this embodiment, the enamelled steel plate body 110 is planar, and its cross section is U-shaped.

[0027] One side of the enamelled steel plate body 110 is provided with a connecting bar 120 . The connecting bar 120 is strip-shaped and arranged along the length direction of the side of the enamelled steel plate body 110 . The cross section of the connecting strip 120 is U-shaped, which is interlocked with the enamelled steel plate body 110. One longitudinal surface 121 is arranged in the inner surface of the wrapping 111 and is superimposed and fixed with the inner surface of the wrapping 111. The other longitudinal surface 122 and the transverse sur...

Embodiment 2

[0029] Embodiment 2 An enamelled steel plate and its construction structure and construction method

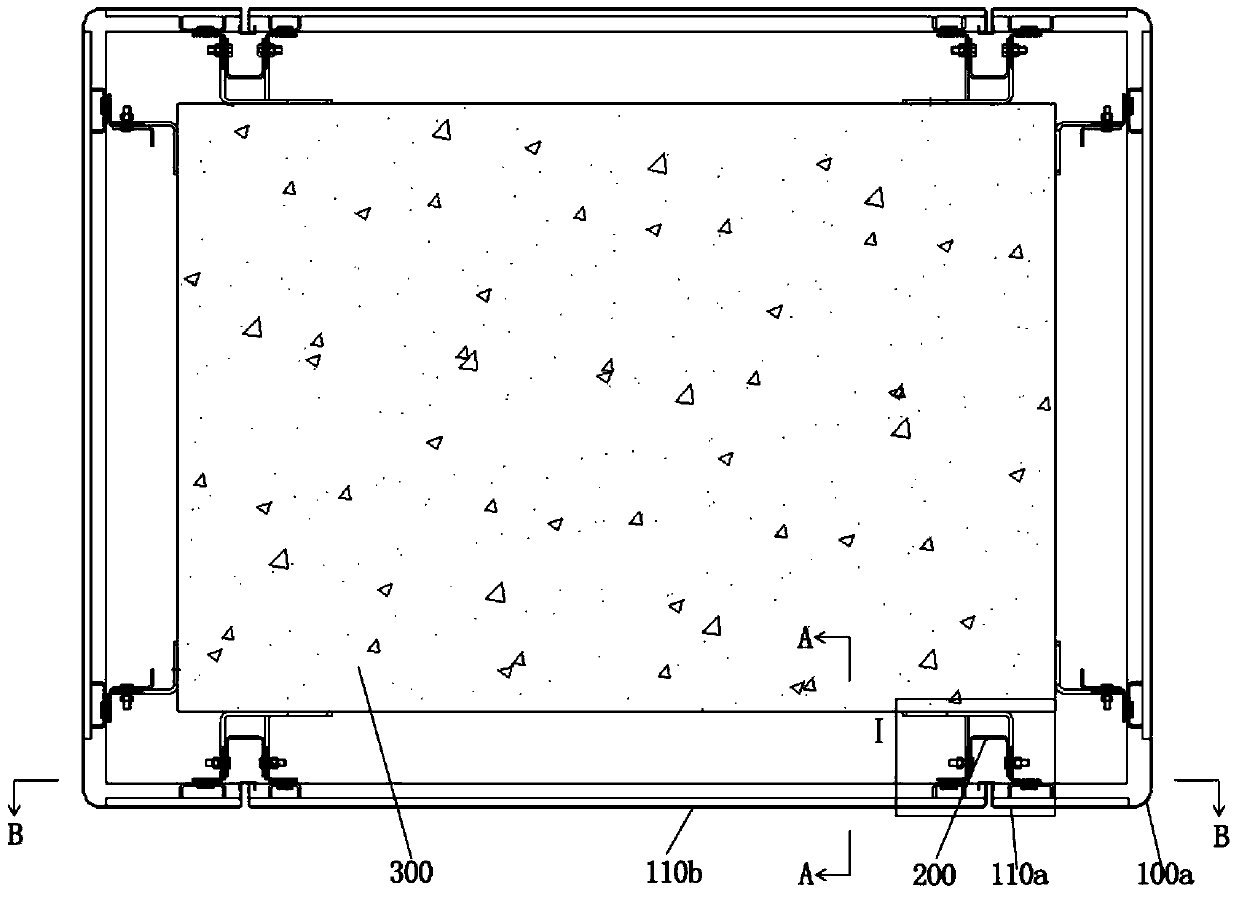

[0030] Such as figure 2 and 3 As shown, this embodiment provides an enameled steel plate 100a, which is the same as the enameled steel plate provided in Embodiment 1, including an enameled steel plate body 110a and a connecting bar 120a; the only difference is that the enameled steel plate body 110a is bent.

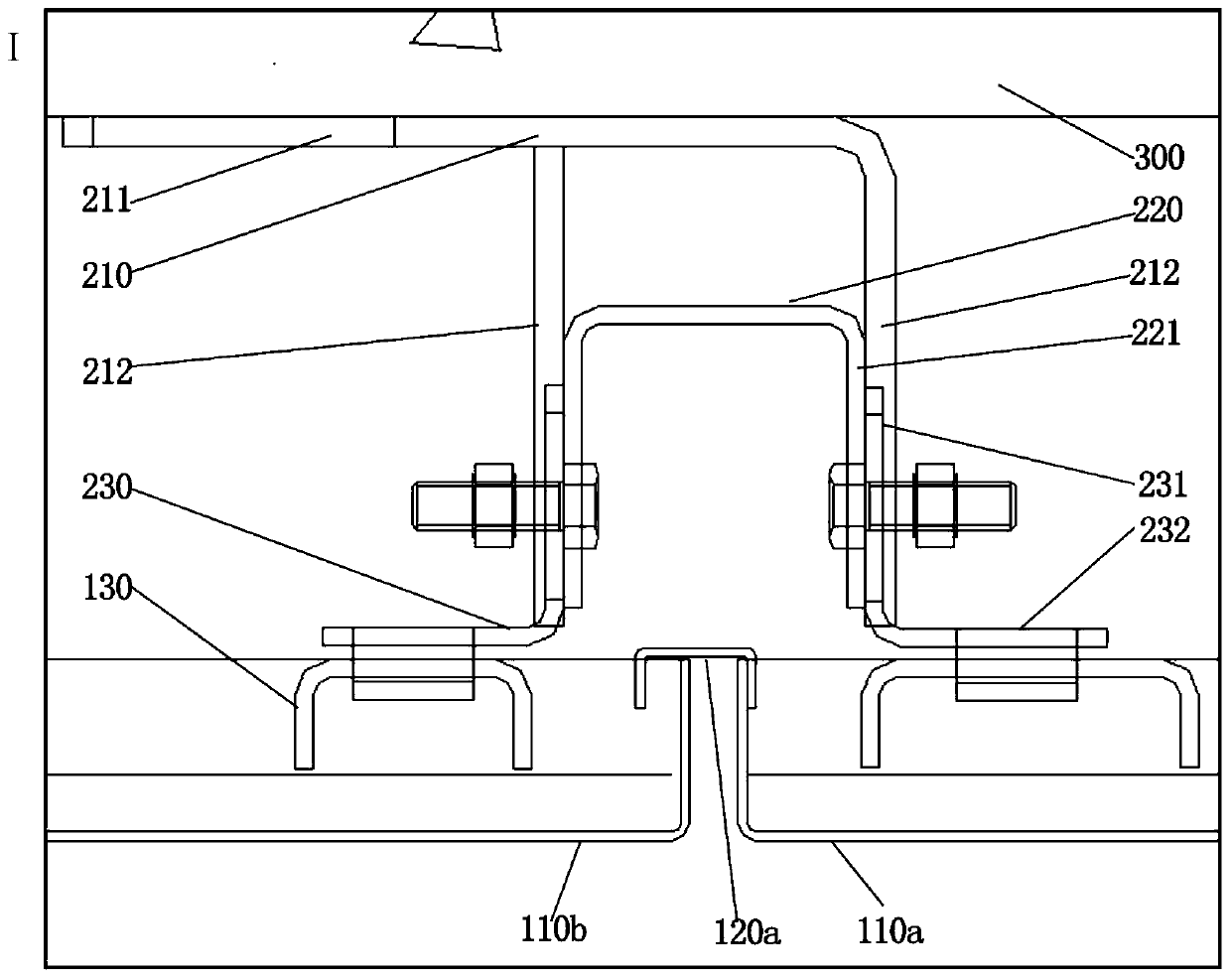

[0031] Such as figure 2 and 3 As shown, this embodiment also provides the construction structure of the enamelled steel plate 100a, including the enameled steel plate 100a, the enameled steel plate body 110b and the installation system 200. This embodiment uses the cylindrical surface 300 as the construction surface to describe the implementation mode in detail.

[0032] The installation system 200 includes a wall member 210 , a keel 220 and a hanger 230 . Wherein, the wall connecting piece 210 is installed on the cylinder 300 , the keel 220 is installed on the wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com