A Segmented Mutual Capacitance Displacement Sensor for Roof Delamination Monitoring

A displacement sensor, top plate separation technology, applied in the direction of using electrical devices, electromagnetic means, instruments, etc., can solve the problems of increasing absolute measurement error and large sensor size, and achieve the effect of reducing requirements and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

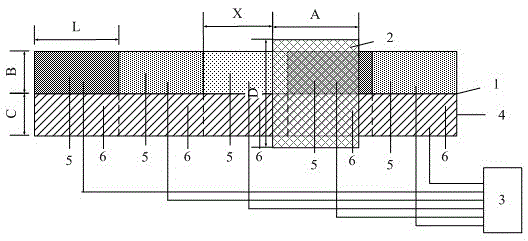

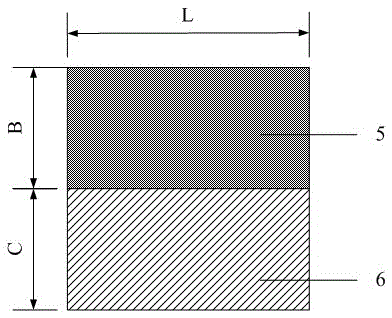

[0033] Embodiment 1: as figure 1 , figure 2 As shown, the segmented mutual capacitance displacement sensor of this embodiment includes a fixed pole plate 1, a sliding pole plate 2 and a capacitance measurement circuit 3, wherein the fixed pole plate 1 is a segmented conductive unit structure, the number is five, and the segment The conductive unit includes a receiving electrode 5 and a transmitting electrode 6. The receiving electrode 5 has a width of 12.7mm and a length of 24.8mm. mm, the shape is square, the material is copper, the total length of the fixed pole plate 1 is 125mm; the width of the sliding pole plate 2 is 30mm, the length is 24.8mm, the quantity is one piece, the shape is square, the material is copper, and the sliding pole plate 2 is used for displacement measurement At most two segmented conductive units can be covered at the same time; the emitting electrodes 6 of each segmented conductive unit are connected together to form the total emitting electrode 4...

Embodiment 2

[0036] Embodiment 2: The fixed pole plate 1 of the present embodiment adopts the silk screen printing method, and according to the accompanying drawings, the conductive paste is printed on the horizontal arm (circle) of the mechanical top plate delamination instrument, and after the conductive layer is printed, coat A layer of insulating layer, the lead-out line of the segmented conductive unit is led to the capacitance measurement circuit with a flexible printed cable, and the main chip is AD7153. The sliding plate 2 is made of circular conductive material. The maximum measurement error of this embodiment is 1.12mm, in a mine 15 # It is better applied in the monitoring of the roof abscission of the return air trough in the coal seam 1501 working face. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com