Automobile insulation resistance detection circuit and method

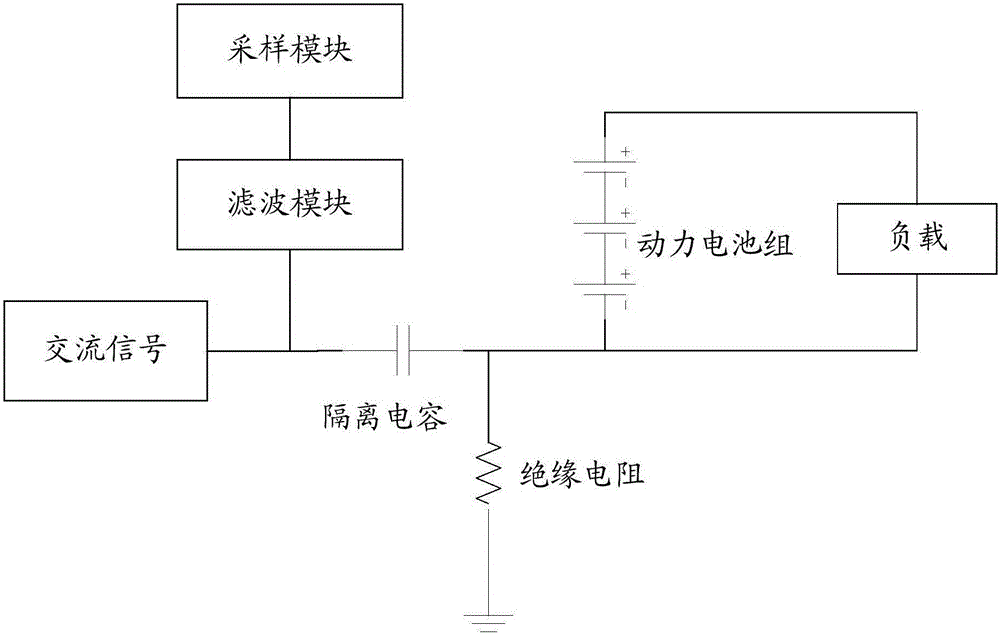

A technology of insulation resistance and detection circuit, which is applied in the direction of measuring resistance/reactance/impedance, high resistance measurement, and measuring devices, etc. It can solve the problems of uncertain insulation detection cycle, long stabilization time, and affecting the accuracy of insulation resistance acquisition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

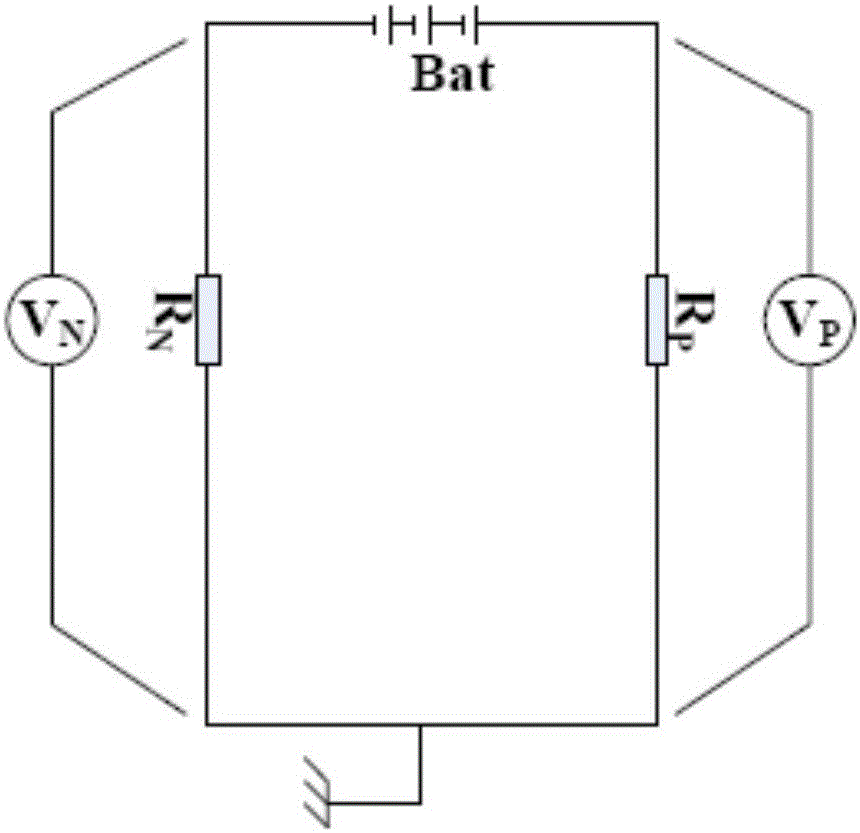

[0041] Embodiment 1 of the present invention provides an automobile insulation resistance detection circuit, Figure 6 It is the automobile insulation resistance detecting circuit diagram of embodiment one of the present invention, as Figure 6 As shown, the automobile insulation resistance detection circuit includes: negative discharge resistor R5, positive discharge resistor R6, first sampling resistor R1, second sampling resistor R2, third sampling resistor R3, fourth sampling resistor R4, fifth sampling resistor R7, sixth sampling resistor R8, negative switch Sn, positive switch Sp;

[0042] One end of the negative discharge resistor R5 is connected to the negative pole of the battery under test of the car, the other end of the negative discharge resistor R5 is grounded, one end of the positive discharge resistor R6 is connected to the positive pole of the battery under test, and the other end of the positive discharge resistor R6 is grounded;

[0043]One end of the first...

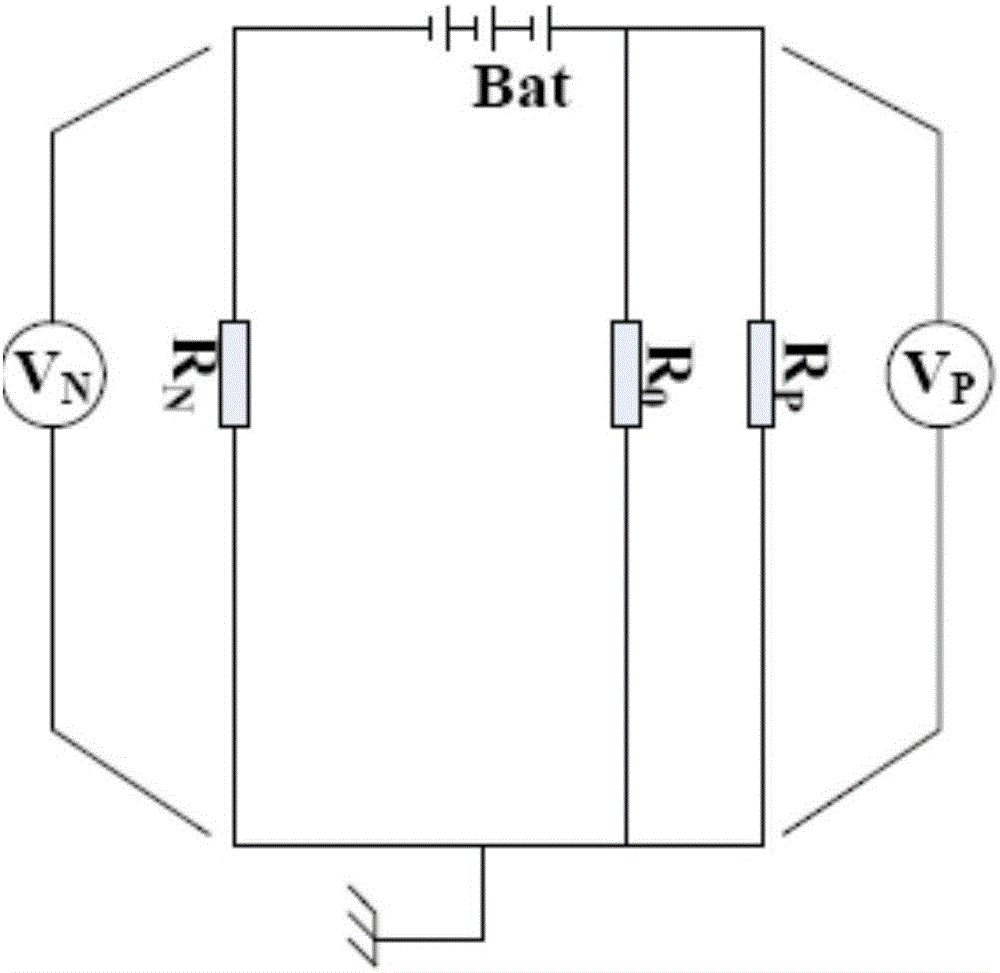

Embodiment 2

[0052] Embodiment 2 of the present invention provides an automobile insulation resistance detection circuit, Figure 8 It is the automobile insulation resistance detection circuit diagram of the second embodiment of the present invention, which shows a schematic diagram of the circuit structure of a preferred example of the automobile insulation resistance detection circuit of the present invention. The detection circuit can contain Figure 8 All shown in , may also include the part involved in Embodiment 1 and Figure 8 One of the parts shown in except the part involved in the first embodiment.

[0053] Such as Figure 8 As shown, the automobile insulation resistance detection circuit in the second embodiment can also include a microcontroller 101 on the basis of the first embodiment, and the microcontroller 101 is used to control the on-off of the negative switch Sn and the positive switch Sp, so as to The automatic control of the negative switch Sn and the positive switc...

Embodiment 3

[0064] Embodiment 3 of the present invention provides an insulation resistance detection method based on the automobile insulation resistance detection circuit in any one of the above embodiments. see Figure 9 As shown, it is a schematic flow chart of the implementation of the insulation resistance detection method according to the third embodiment of the present invention. Such as Figure 9 As shown, the insulation resistance detection method of the third embodiment includes the following steps:

[0065] Step S201: closing the negative pole switch and the positive pole switch to obtain the first negative pole-to-ground voltage value and the first positive pole-to-ground voltage value;

[0066] Step S202: Determine whether the first negative pole-to-ground voltage value is greater than the first positive pole-to-ground voltage value, if yes, go to step S203, if not, go to step S205;

[0067] Step S203: Turn off the negative pole switch, and acquire the second positive pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com