Wafer divider and wafer division method

一种晶片、载置的技术,应用在精细的工作装置、电气元件、电固体器件等方向,能够解决增加分割、分割晶片、困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

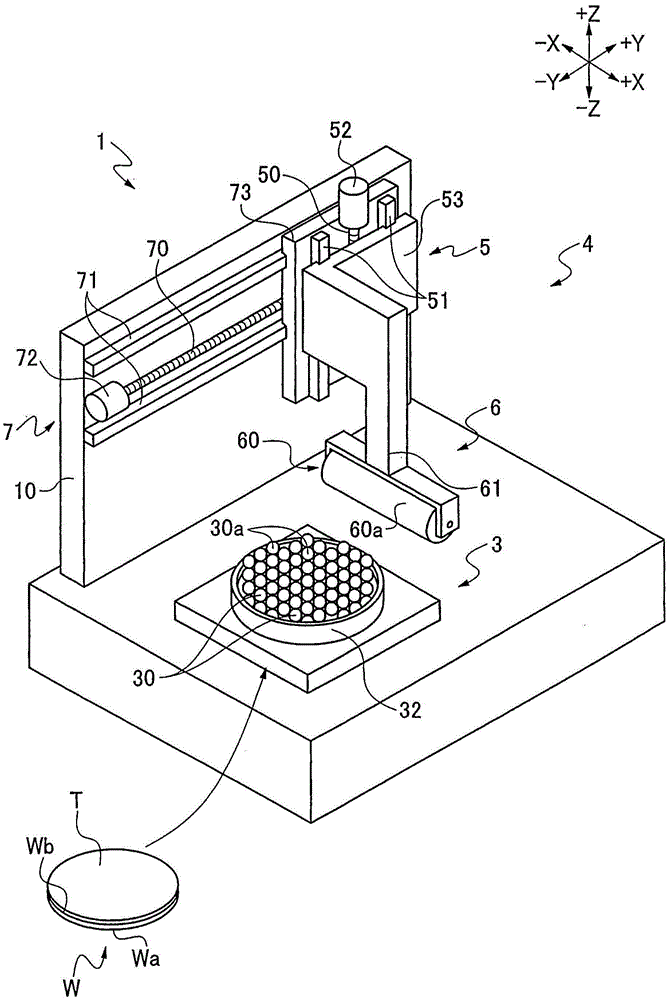

[0025] figure 1 The shown splitting device 1 is a device for splitting a wafer W placed on a mounting table 3 into a plurality of chips by a splitting unit 4 .

[0026] Such as figure 1 As shown, a mounting table 3 is disposed on the dividing device 1 . The mounting table 3 has a plurality of spherical bodies 30 and a container 32 for accommodating the plurality of spherical bodies 30 in close contact.

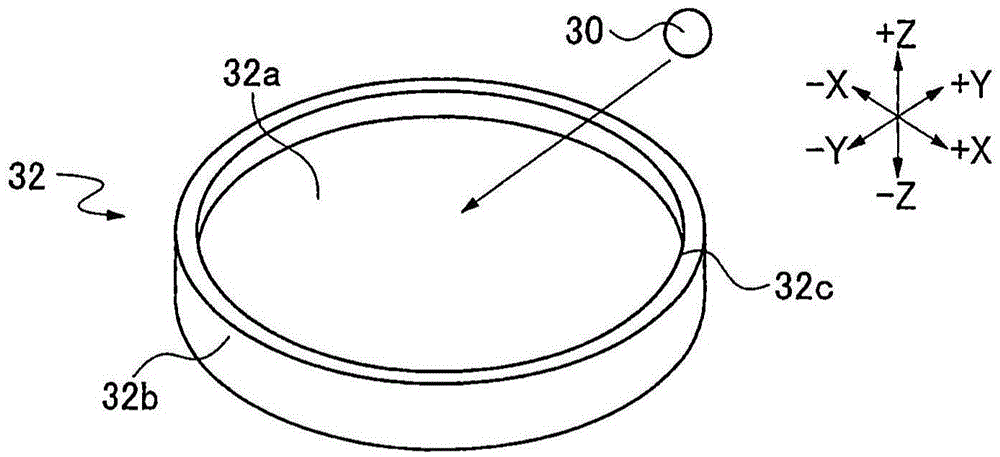

[0027] figure 2 The shown container 32 is composed of, for example, a disc-shaped bottom plate 32a and a side plate 32b vertically erected from the outer peripheral portion of the bottom plate 32a in the +Z direction, and can be placed in the same space in the space surrounded by the bottom plate 32a and the side plate 32b. The spherical body 30 is arranged in a plurality of spaces of the diameter. In addition, the outer shape of the bottom plate 32a is not limited to a disc shape, and may be a quadrangle or the like.

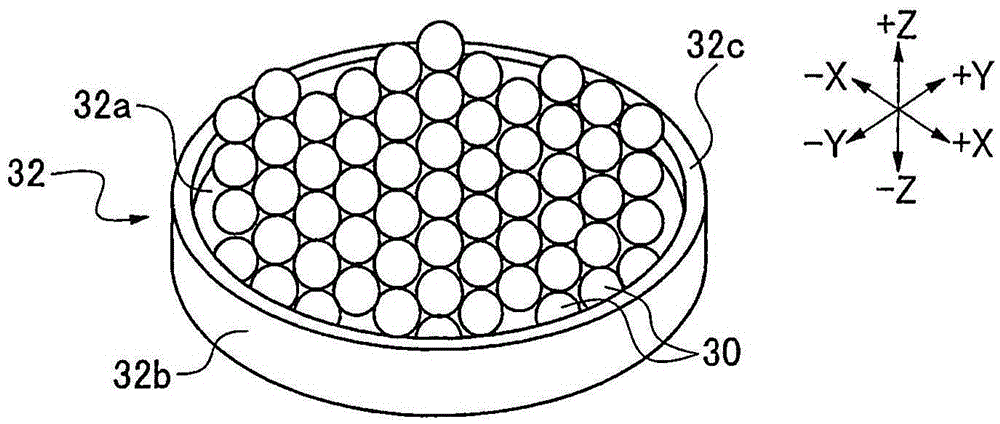

[0028] Such as image 3 As shown, in the space sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com