Anti-condensation method and device for enclosed busbar of hydrogen-cooled generator

A hydrogen-cooled generator and closed busbar technology, which is applied in fully enclosed busbar installations, busbar installations, cable installations, etc., can solve generator outlet grounding short-circuit accidents, closed busbar condensation, failure to meet clean and dry air requirements, etc. problem, to avoid insulation drop, prevent closed bus explosion, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

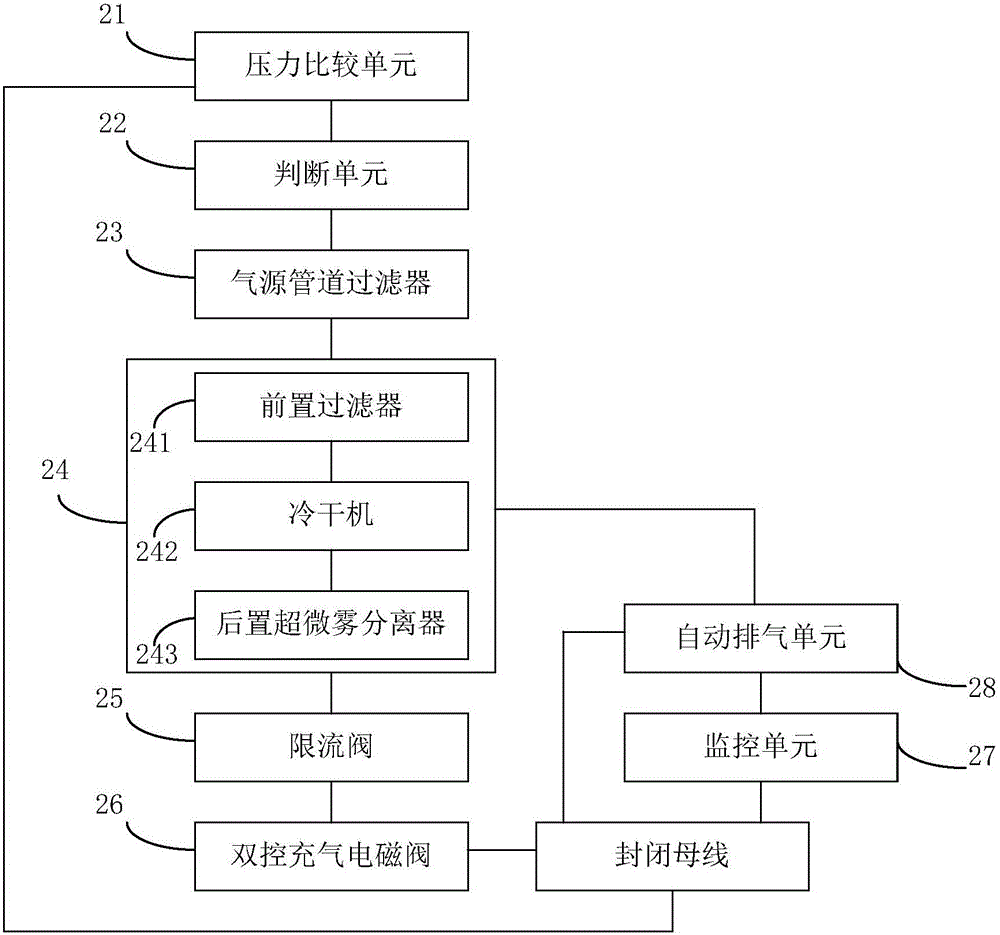

[0034] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

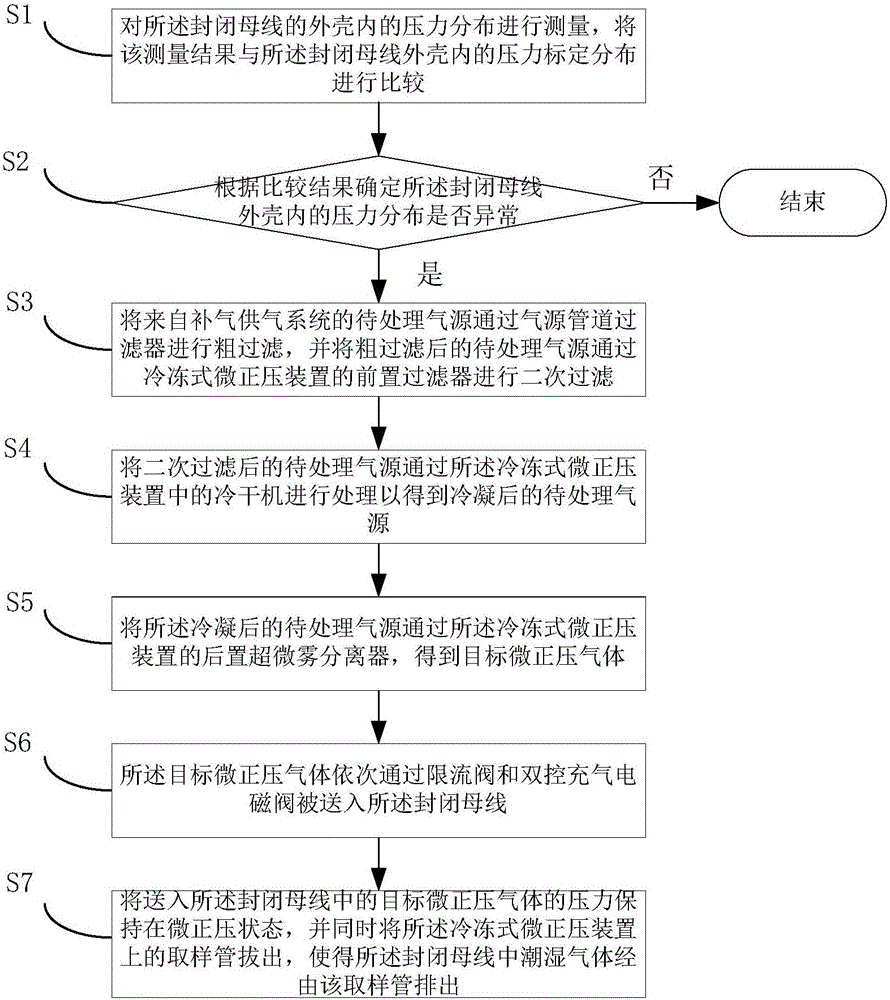

[0035] The anti-condensation method for a closed busbar of a hydrogen-cooled generator according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings. Such as figure 1 As shown, the anti-condensation method for the closed busbar of the hydrogen-cooled generator comprises the following steps:

[0036] S1: Measure the pressure distribution in the enclosure of the enclosed busbar, and compare the measurement result with the pressure calibration distribution in the enclosure of the enclosed busbar.

[0037] Generally speaking, the existing micro-positive pressure device for hydrogen-cooled generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com