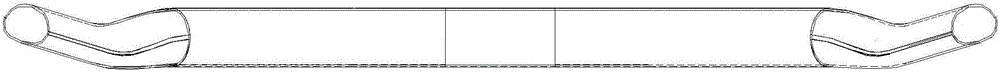

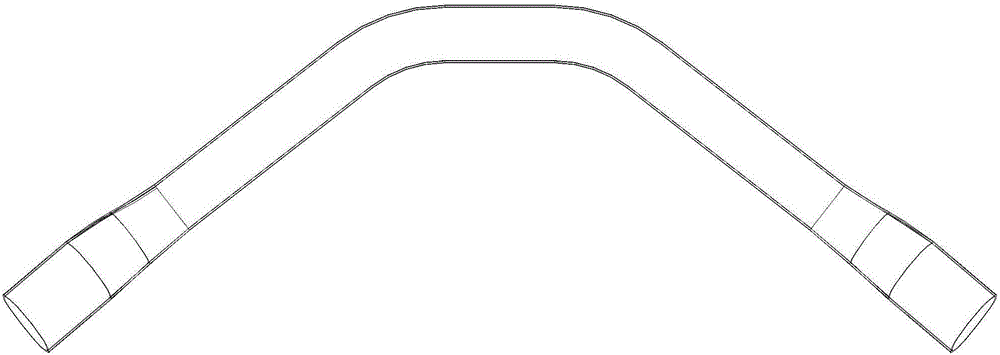

End punching die of automotive chassis suspension upper bending pipe fitting semi-finished product

A technology for automobile chassis and bending pipes, which is used in perforating tools, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to connect production, high logistics turnover costs, and low production efficiency of CNC machine tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

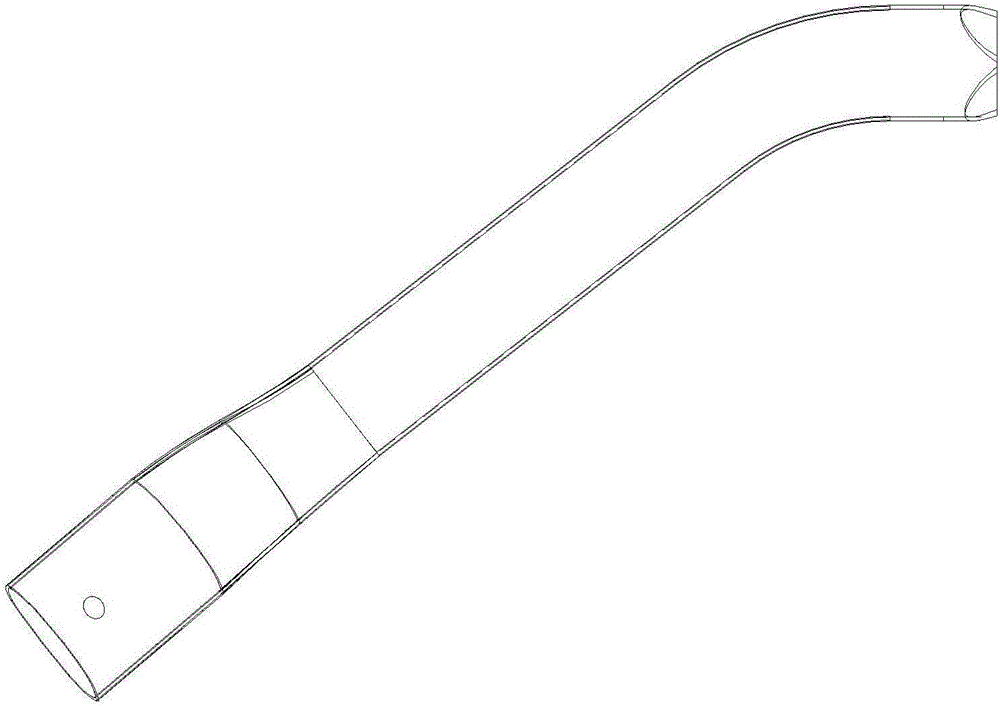

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] like Figure 4 As shown in -5, an end punching die for the semi-finished product of bending pipe fittings on the chassis suspension of an automobile, including an upper mold base 8 and a lower mold base 1;

[0028] The lower mold base 1 is provided with a left material holder 2 and a right material holder 3 arranged side by side. The left material chute, the right material chute 3 is provided with the right material chute, and the lower mold base 1 is provided with sliding blocks 4 at the two ends of the left material 2 and the right 3 respectively, The lower mold base 1 is provided with four nitrogen gas springs that respectively drive the four sliding blocks 4 to reset. The sliding block 4 is provided with a mandrel 5 that matches the shape of the inner end surface of the workpiece to be processed. The corresponding forming hole of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com