Packaging bag opening device

A packaging bag and piston rod technology, applied in the field of packaging bag opening device, can solve the problems of high energy consumption, large space occupation of vacuum pump, complicated maintenance of solenoid valve and electric control, etc., and achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

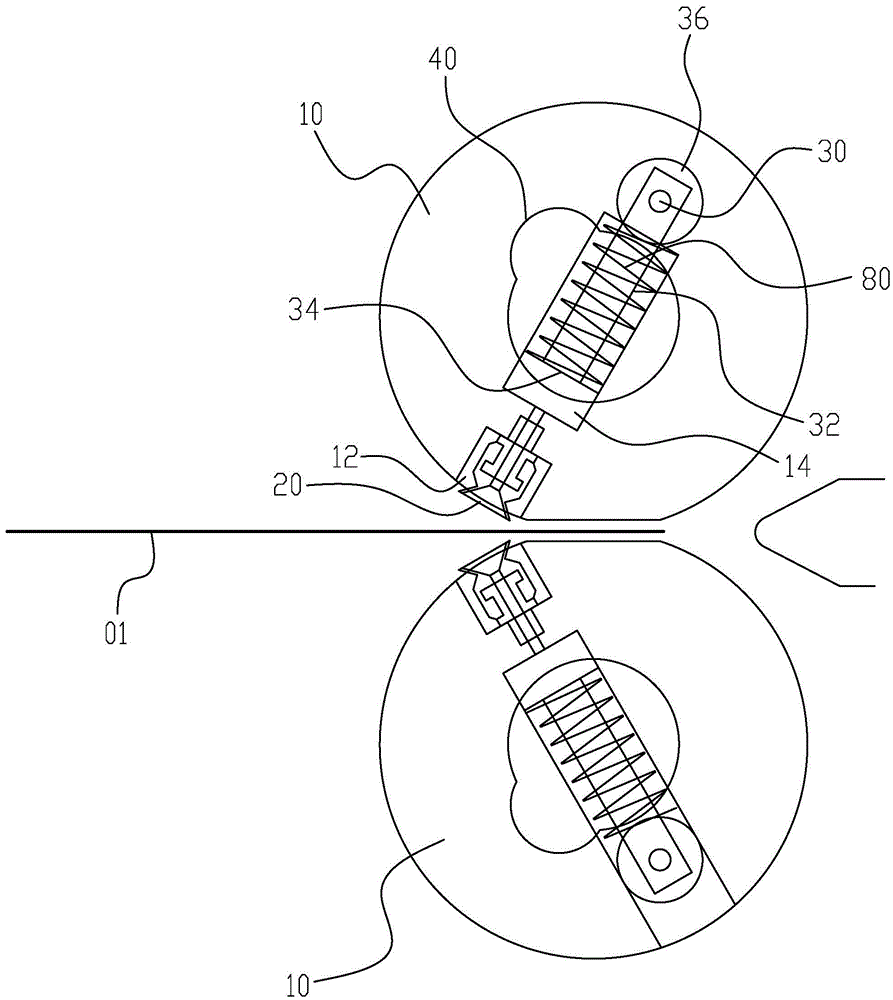

[0028] Please refer to figure 1 , a packaging bag opening device of the present invention includes two rollers 10 symmetrically arranged on both sides of the packaging bag 01, the outer peripheral surface of the rollers 10 is provided with a suction nozzle 20, and the outer surface of the rollers 10 is A groove 12 is provided, and the suction nozzle 20 is located in the groove 12; the suction nozzle 20 is connected with a suction mechanism 30 for pumping air and generating suction, the suction nozzle 20, the roller 10, the suction mechanism 30 and the three rotate synchronously; the pumping mechanism 30 includes a reciprocatingly movable piston rod 32, a piston 34 connected to the bottom end of the piston rod 32, and a bearing 36 connected to the top end of the piston rod 32; When leaning on the packaging bag 01, push the piston rod 32 to move upwards to make the suction nozzle 20 generate suction to absorb the fixed bump 40 of the packaging bag 01, and to push the piston rod ...

Embodiment 2

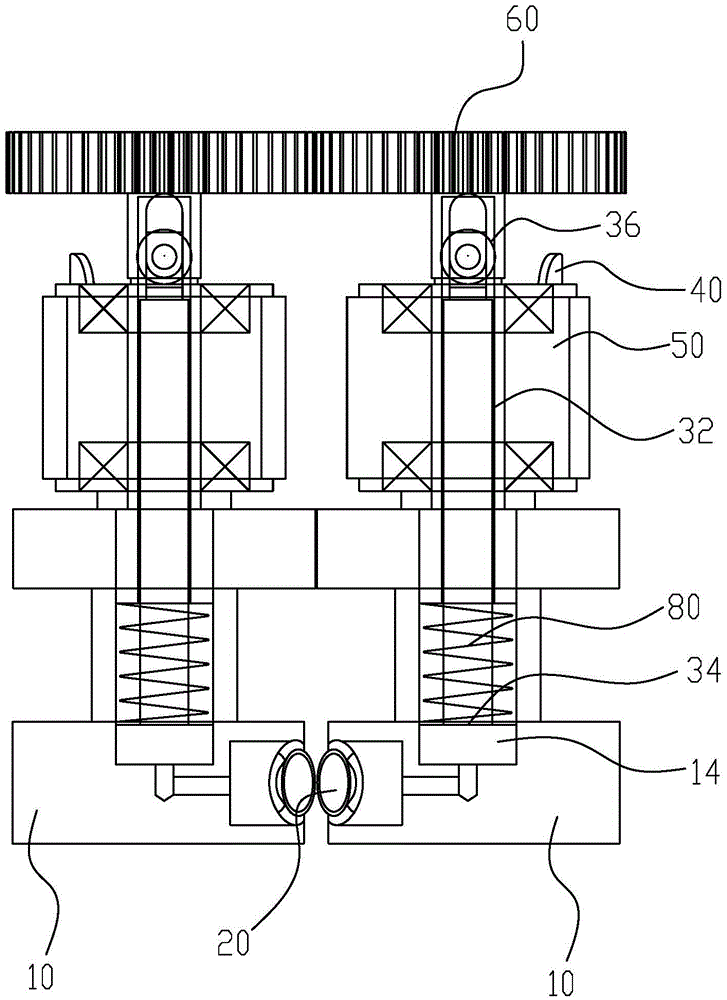

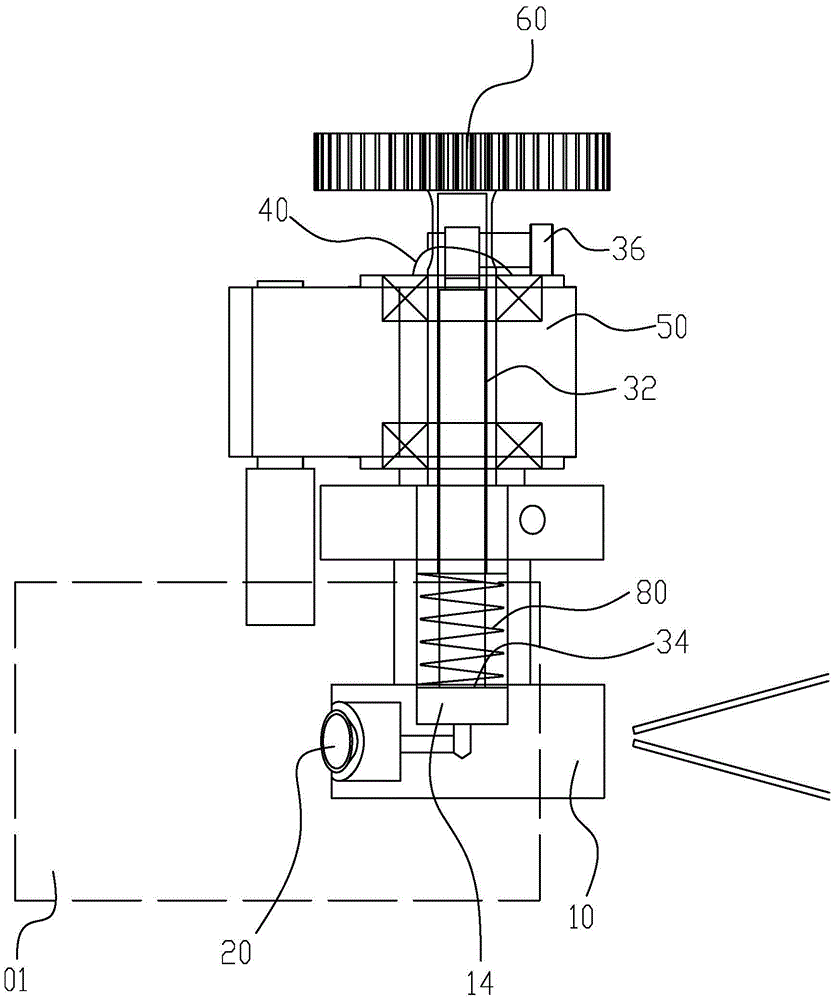

[0032] Please refer to Figure 2 to Figure 4 The difference between the second embodiment and the first embodiment is that the chamber 14 has a circular groove structure and is located at the center of the end surface of the roller 10; it also includes a bearing seat 50 through which the piston rod 32 passes; the bearing 36 is connected On the side of the piston rod 32 top, the fixed projection 40 is arranged above the bearing seat 50, and the fixed projection 40 and the bearing seat 50 are located on the same circumference; the top of the piston rod 32 is connected with a gear 60, and the two piston rods 32 The gear 60 is engaged; the reset member 80 is sleeved on the piston rod 32 and generates a downward force on the piston 34 .

[0033] By arranging the bearing seat 50 and extending the piston rod 32 to the outside of the roller 10, the moment arm can be increased, so that the suction mechanism can generate greater suction force.

[0034] The piston rod 32 and the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com