A new method for preparing dental colored nano-zirconia powder

A nano-zirconia, a new method technology, applied in zirconia, dental prosthesis, dentistry, etc., can solve the problems of large particle surface energy, poor powder dispersibility, and easy agglomeration of particles, so as to achieve uniform powder particle size and low cost. Low, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

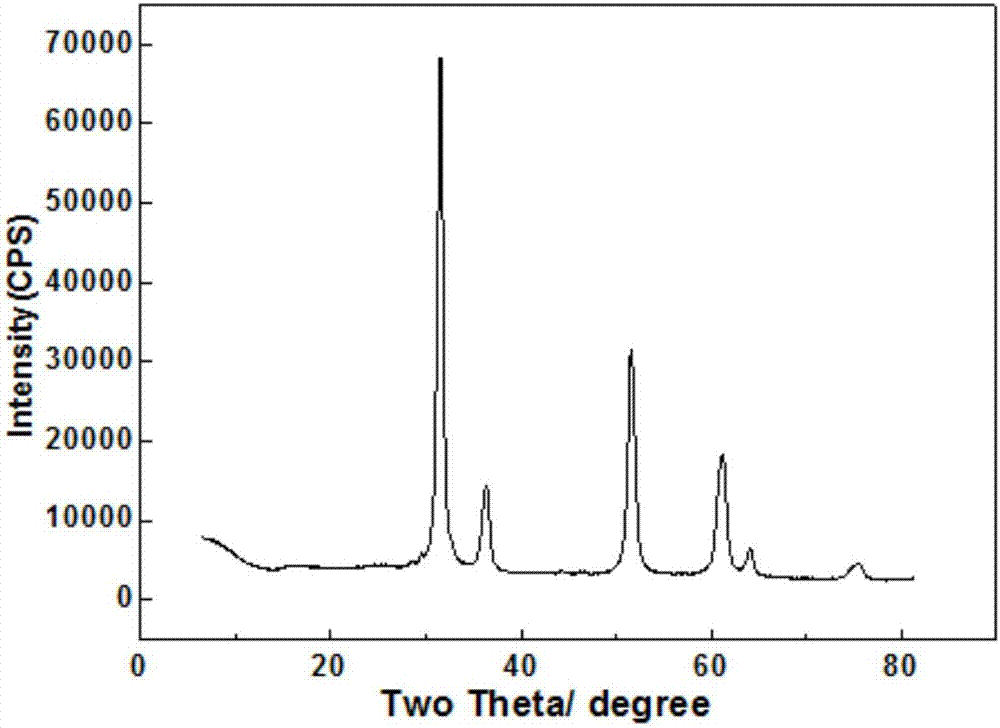

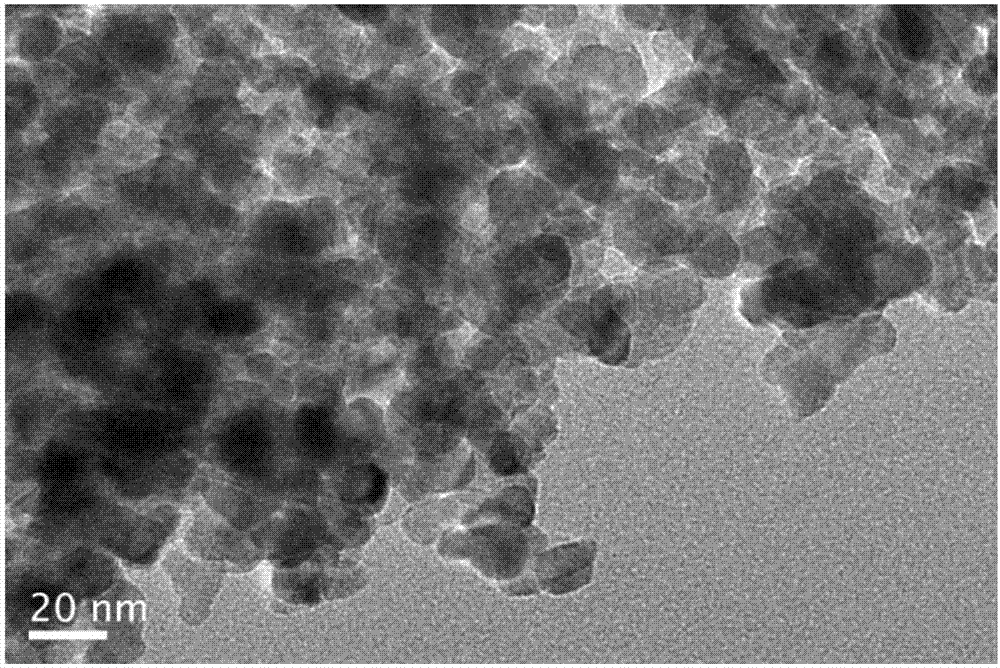

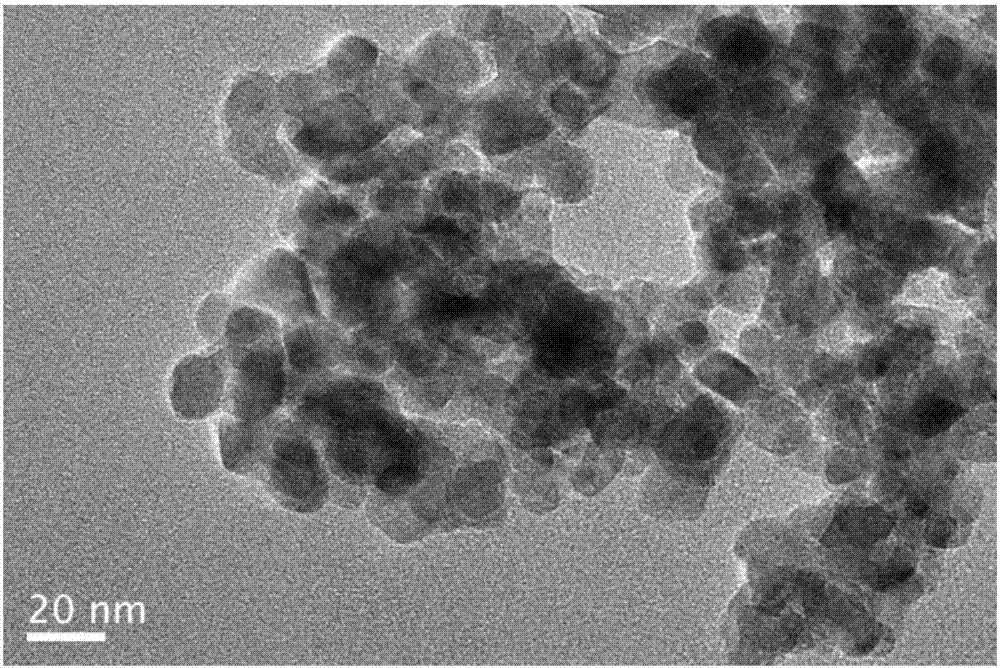

[0032] ZrOCl 2 ·8H 2 O, Y (NO 3 ) 3 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, Ce(NO 3 ) 3 ·6H 2 O, Er(NO 3 ) 3 ·6H 2 After O is dissolved in deionized water respectively, stir and mix to form a mixed solution of zirconium salt, yttrium salt and colorant; the concentration of zirconium salt, yttrium salt and colorant mixed solution is 0.6mol / L; the total amount of mixed solution is 1mol calculation, ZrOCl 2 ·8H 2 O is 0.95mol, Y 2 o 3 0.05mol; iron oxide 800ppm, cerium oxide 500ppm, erbium oxide 500ppm; dispersant absolute ethanol was added to the mixed solution and ammonia solution, stirred, and constant volume; the amount of absolute ethanol accounted for zirconium salt, yttrium salt and colorant 20% of the volume of the mixed solution and the aqueous ammonia solution; the amount of the ammonia solution is 10% excessive on the basis of meeting the amount required for the chemical reaction with the zirconium salt, yttrium salt and coloring agent, so as to adjust the pH valu...

Embodiment 2

[0034] ZrOCl 2 ·8H 2 O, Y (NO 3 ) 3 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, Ce(NO 3 ) 3 ·6H 2 O, Er(NO 3 ) 3 ·6H 2 After O is dissolved in deionized water respectively, stir and mix to form a mixed solution of zirconium salt, yttrium salt and colorant; the concentration of zirconium salt, yttrium salt and colorant mixed solution is 0.6mol / L; the total amount of mixed solution is 1mol calculation, ZrOCl 2 ·8H 2 O is 0.95mol, Y 2 o 3 0.05mol; iron oxide 1000ppm, cerium oxide 500ppm, erbium oxide 500ppm; the dispersant absolute ethanol was added to the mixed solution of zirconium salt, yttrium salt and coloring agent and ammonia solution, stirred and constant volume; the amount of absolute ethanol was respectively Accounting for 20% of the volume of the mixed solution of zirconium salt, yttrium salt and colorant and the volume of ammonia water solution; the amount of ammonia solution is 10% in excess of the amount required for chemical reaction with zirconium salt, yttrium s...

Embodiment 3

[0036] ZrOCl 2 ·8H 2 O, Y (NO 3 ) 3 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, Ce(NO 3 ) 3 ·6H 2 O, Er(NO 3 ) 3 ·6H 2 After O is dissolved in deionized water respectively, stir and mix to form a mixed solution of zirconium salt, yttrium salt and colorant; the concentration of the mixed solution of zirconium salt, yttrium salt and colorant is 0.6mol / L; The total amount of the mixed solution with the colorant is calculated as 1mol, ZrOCl 2 ·8H 2 O is 0.95mol, Y 2 o 3 0.05mol; iron oxide 1200ppm, cerium oxide 500ppm, erbium oxide 500ppm; dispersant absolute ethanol is added zirconium salt, yttrium salt and coloring agent mixed solution and ammonia solution respectively, stirs, constant volume; The amount of absolute ethanol accounts for respectively 20% of the volume of zirconium salt, yttrium salt and colorant mixed solution and ammonia water solution; the amount of ammonia solution is 10% in excess of the amount required for chemical reaction with zirconium salt, yttrium salt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com