Reinforcing method and structure for earth-retaining oblique wall

A technology for retaining sloping walls and reinforcing structures, which is applied to underwater structures, infrastructure engineering, excavation, etc., can solve problems such as high cost and troublesome construction, and achieve the effect of reducing waste and improving material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

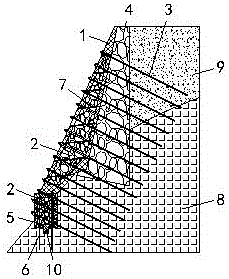

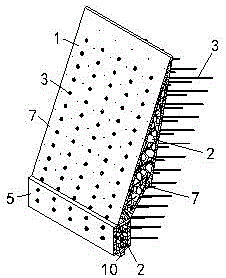

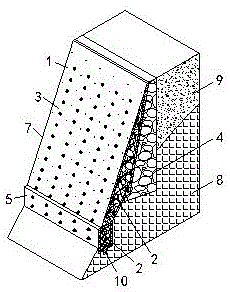

[0019] This example picture 1-3 As shown, it is made of thin-walled cavities to reinforce the walls 1 , thin-walled cavity base with tenons 5 , Anchor 3 with basic reinforcement 6 The support and reinforcement structure composed of thin-walled cavity reinforcement walls 4 Drain pipe installed inside 7 . Thin-Walled Cavity Reinforced Walls 4 with thin-walled cavity base with tenons 5 Filled with graded homogeneous stones 2 . Thin-Walled Cavity Reinforced Walls 4 with thin-walled cavity base with tenons 5 The material is reinforced concrete. Retaining wall to be reinforced 4 The surface should be brushed. Anchor 3 Construction should be carried out first, going deep into the retaining wall to be reinforced 4 inside, and with the retaining wall to be reinforced 4 An effective tie is formed on the inside, and the outside end should meet the thin-walled cavity reinforcement wall 1 with thin-walled cavity base with tenons 5 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com