Dredger of improved structure

A technology to improve the structure and dredger, which is applied in the field of ships, can solve the problems of complicated equipment composition and control, energy waste, and inability to cooperate with each other, so as to achieve the effect of improving energy utilization rate, improving economic benefits, and reducing direct impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

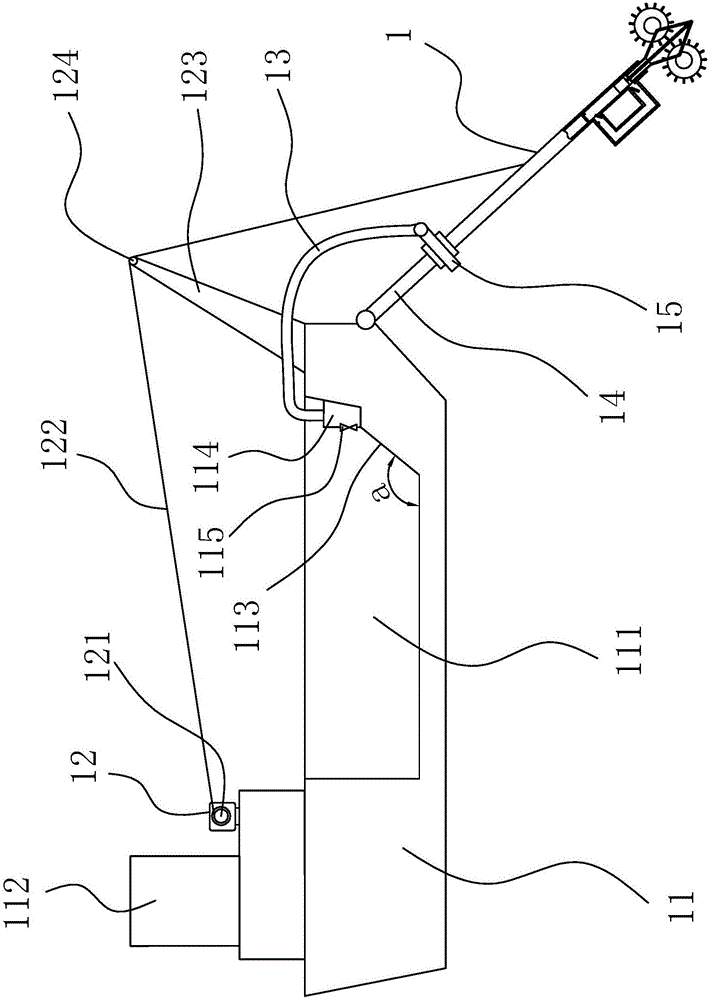

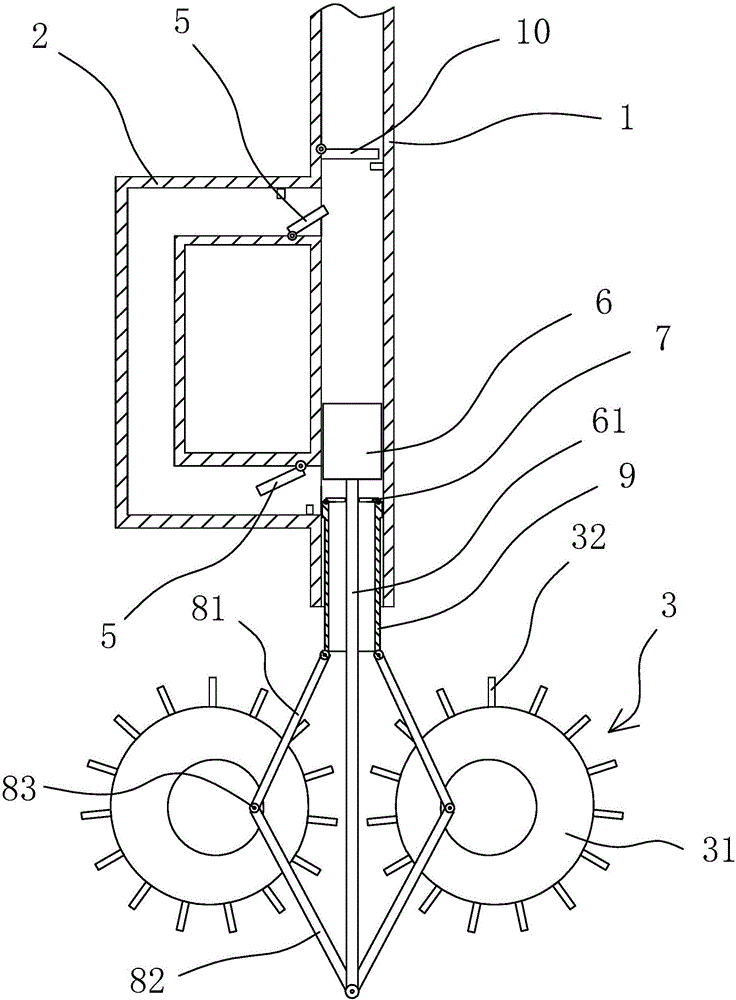

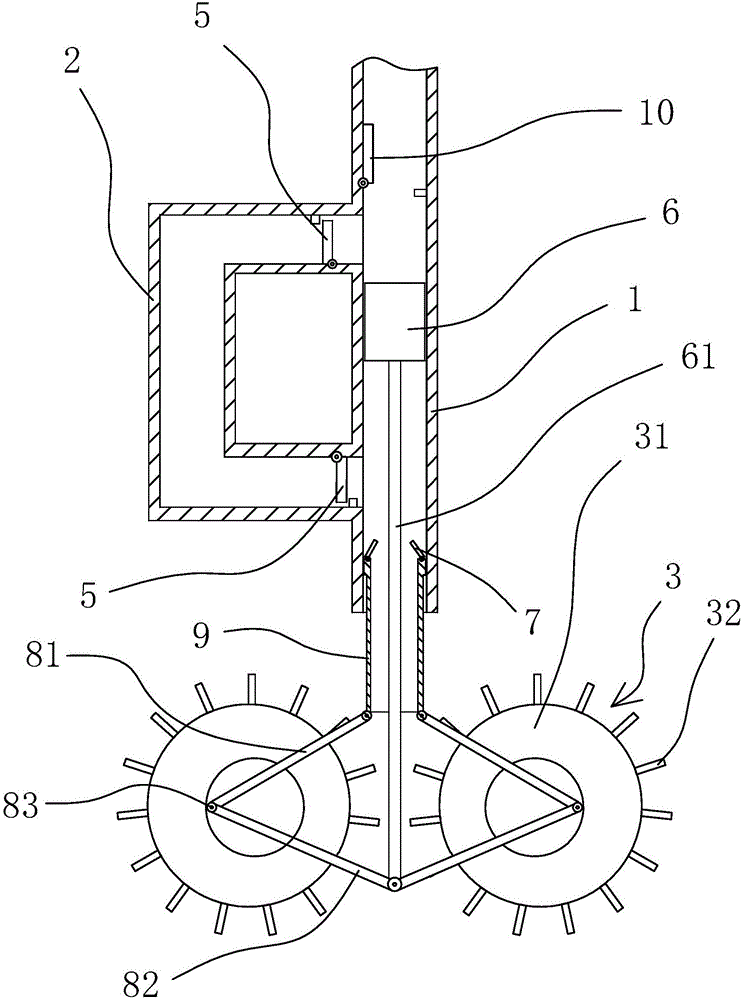

[0028] Such as Figure 1-4As shown, a dredger with an improved structure includes a hull 11, a mud tank 111 is provided inside the hull 11, a fixed frame 14 is hinged on the bow of the hull 11, and a suction bracket 14 is arranged on the fixed frame 14. A mud pump 15, the inlet of the dredge pump 15 communicates with one end of the dredging main pipe 1, the other end of the dredging main pipe 1 is provided with a sediment collection device, the outlet of the dredging pump 15 is connected to the mud discharge pipe 13 The other end of the mud discharge pipe 13 communicates with the mud tank 111, and the sand collection device includes a bypass pipe 2, two sand mining wheels 3 for collecting sand and two sand mining wheels th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com