Automatic-positioning building handing basket device

An automatic positioning and hanging basket technology, applied in construction, building structure, accessories of scaffolding, etc., can solve the problems of hanging basket shaking, hoisting wire rope breakage, building exterior wall damage, etc., and achieves simple transmission mechanism design and stable work. The effect of improving the performance and improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

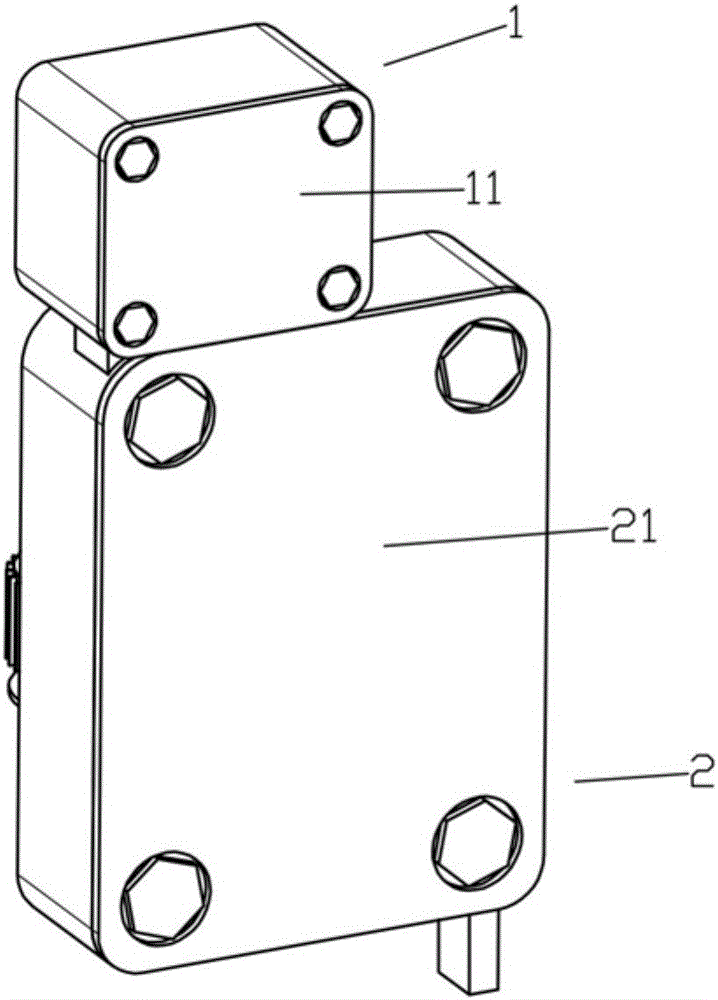

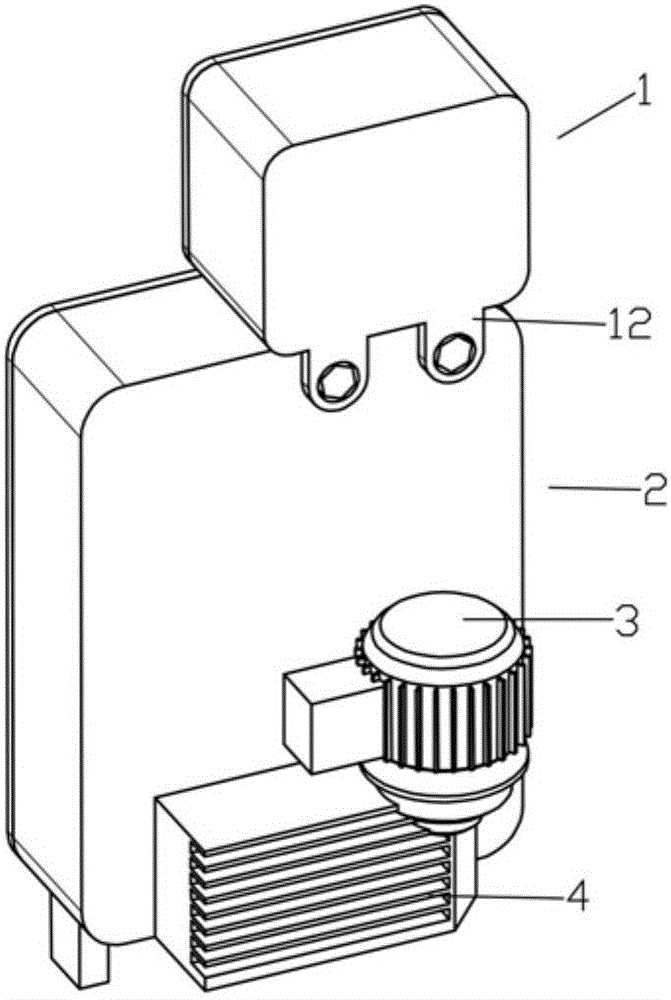

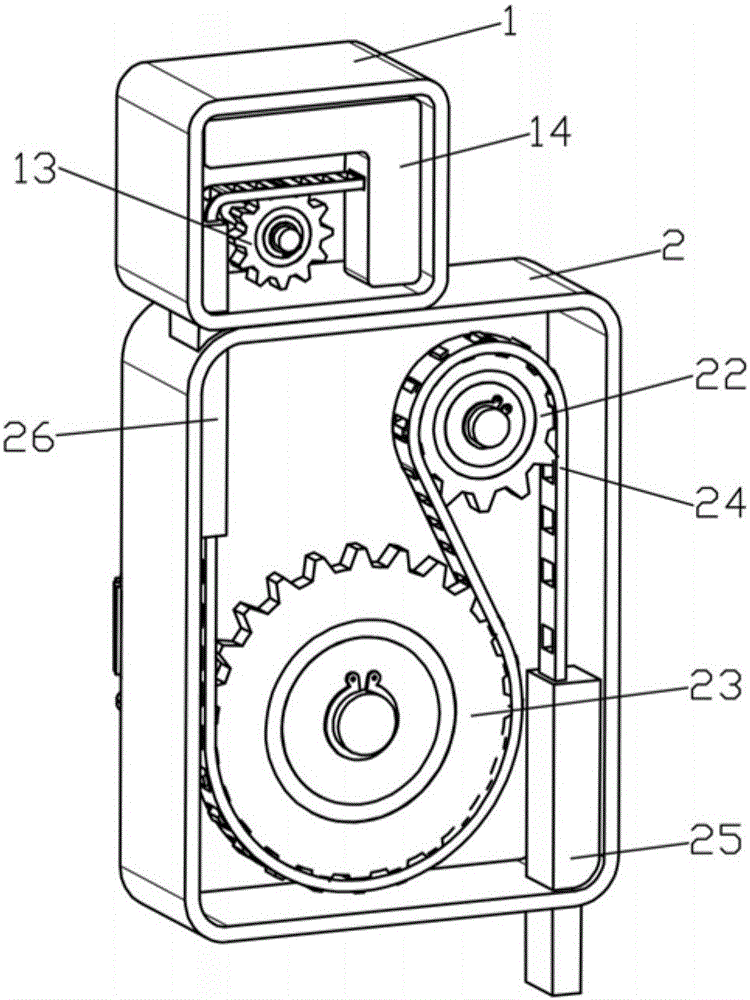

[0019] Such as Figure 1-4 As shown, the automatic positioning construction hanging basket device includes a supporting mechanism, a chain transmission mechanism, a hanging basket main body and a control mechanism. The supporting mechanism is installed on the top of the building, and the chain driving mechanism is arranged on the supporting mechanism. connected, the control mechanism is fixed on the support mechanism and electrically connected with the chain transmission mechanism; the main body of the hanging basket 5 includes a bottom plate 51, the bottom plate 51 is a rectangular structure, and the bottom plate 51 has an uneven anti-skid portion 511, and the bottom of the bottom plate 51 is close to the wall One side is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com