Air valve for inflatable bag

A technology of inflatable bags and air valves, applied in the field of buffer air bags, can solve the problems of easy folding of the air-sealing film, low production efficiency, and small inflatable space, so as to solve the problems of easy flipping, improve production efficiency, and increase air outlet space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

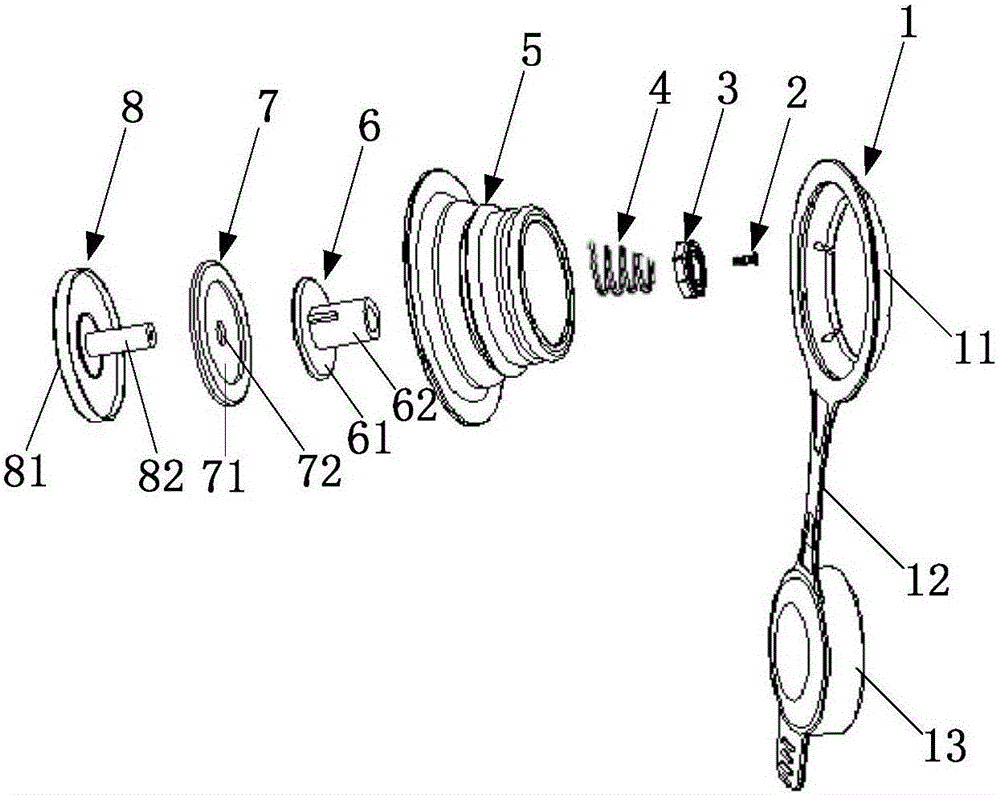

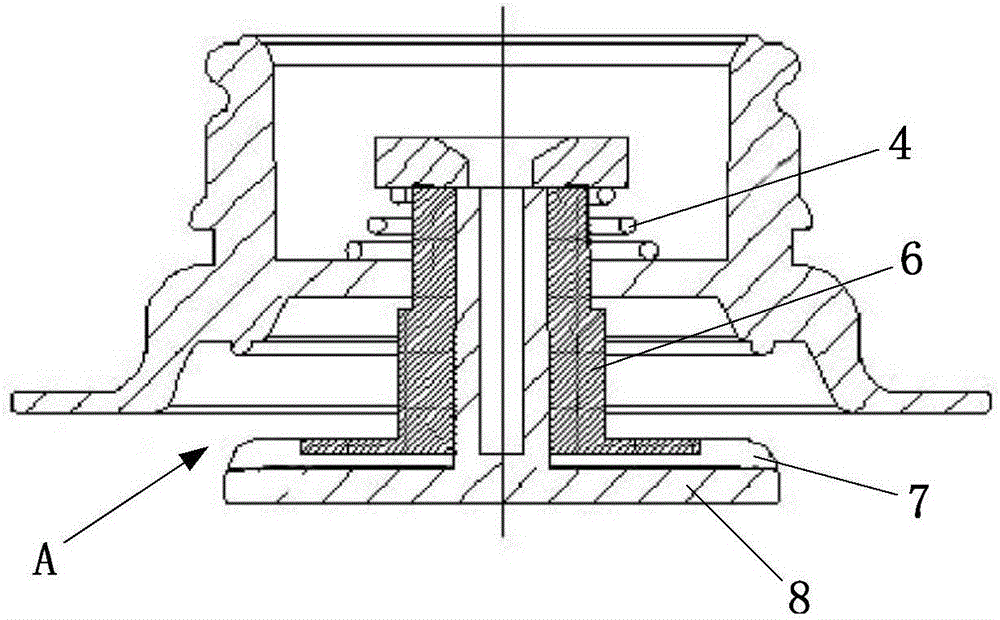

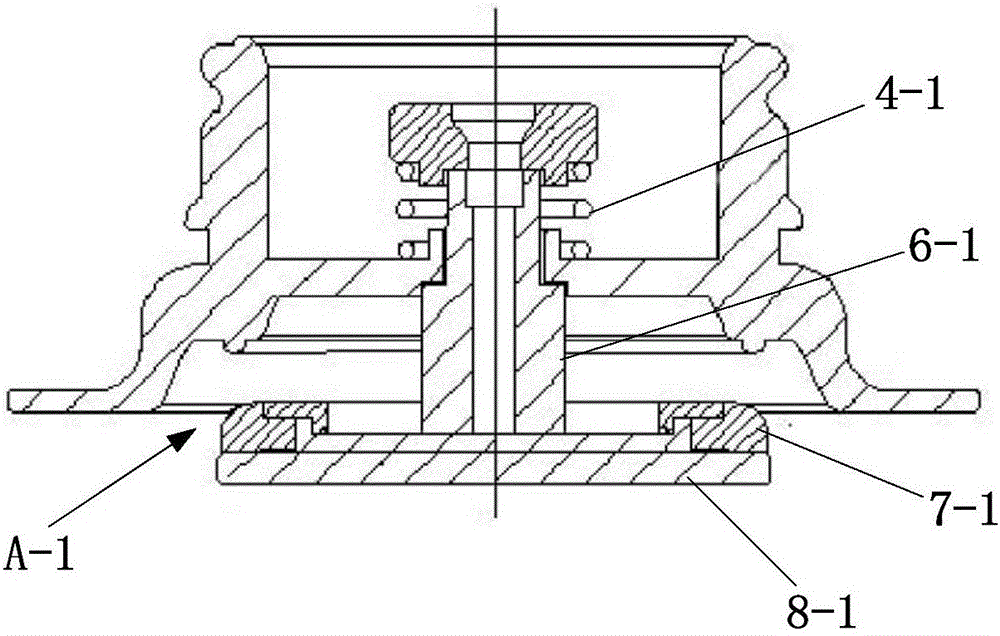

[0032] attached figure 1 Shown is a schematic diagram of the explosion structure of the present invention, which includes: dust cover 1, locking screw 2, latch 3, spring 4, body 5, cylinder core pressing piece 6, sealing rubber pad 7 and cylinder core 8. The cylinder core 8 includes a cylinder core disk 81 and a cylinder core tube 82, and the cylinder core tube 82 is located in the middle of the cylinder core disk 81 and integrally formed therewith. The core pressing piece 6 includes a pressing piece 61 and a sleeve 62, and the sleeve 62 is located in the middle of the pressing piece 61 and integrally formed therewith. The sealing rubber pad 7 is disc-shaped and has a central hole 72 in the middle. The middle part of the body 5 is provided with a support frame.

[0033] The connection relationship between the above parts is: the column core tube 82 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com